Sanitary type side-blowing air distribution plate

An air distribution board and hygienic technology, applied in the field of fluidized bed, can solve the problems of increased processing difficulty, increased cost, high temperature denaturation, etc., and achieve the effect of easy control of size and processing, reduced processing difficulty and cost, and guaranteed strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

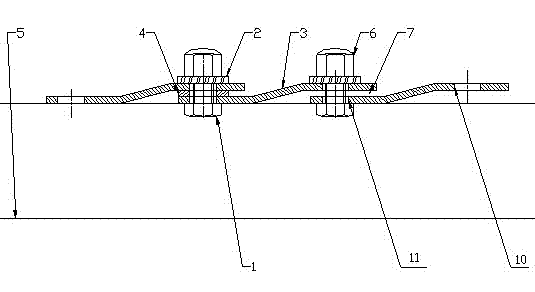

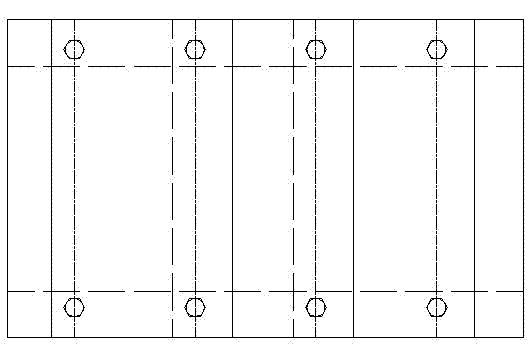

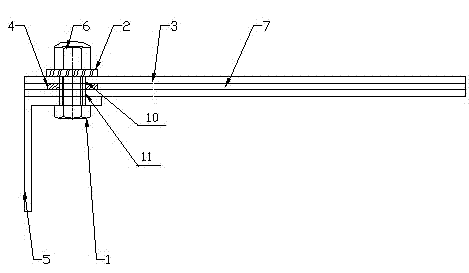

Examples

Embodiment 2

[0026] Example two such as Figure 4 As shown, the lower bolt hole ends of the various shaped slats 3 are bent downward to form a vertical reinforcement 8, and the ratio of the height of the vertical reinforcement 8 to the width of the special-shaped slat 3 is between 0.1:1 and 10:1. between. Through the design of the vertical reinforcement 8 of the special-shaped slat itself, the strength of each special-shaped slat 3 is sufficient, and the strength can be guaranteed without the base plate 9, which reduces the processing difficulty and cost.

[0027] Embodiments are not limited to the above methods, such as Figure 5 As shown, a base plate 9 is set below each shaped slat 3, and the base plate 9 is provided with air inlet strip holes, bolt holes, and reinforced slats.

[0028] In the present invention, the various shaped slats 3 constitute air distribution channels without dead angles, which are very suitable for hygienic fluidized beds. The present invention can be applied ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com