Method for testing hydrogen diffusivity or permeability in metal and specific device therefor

A technology for testing device and penetration performance, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of test signal interference, low vacuum, affecting test accuracy, etc., and achieve the effect of improving test accuracy and accurate flow value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

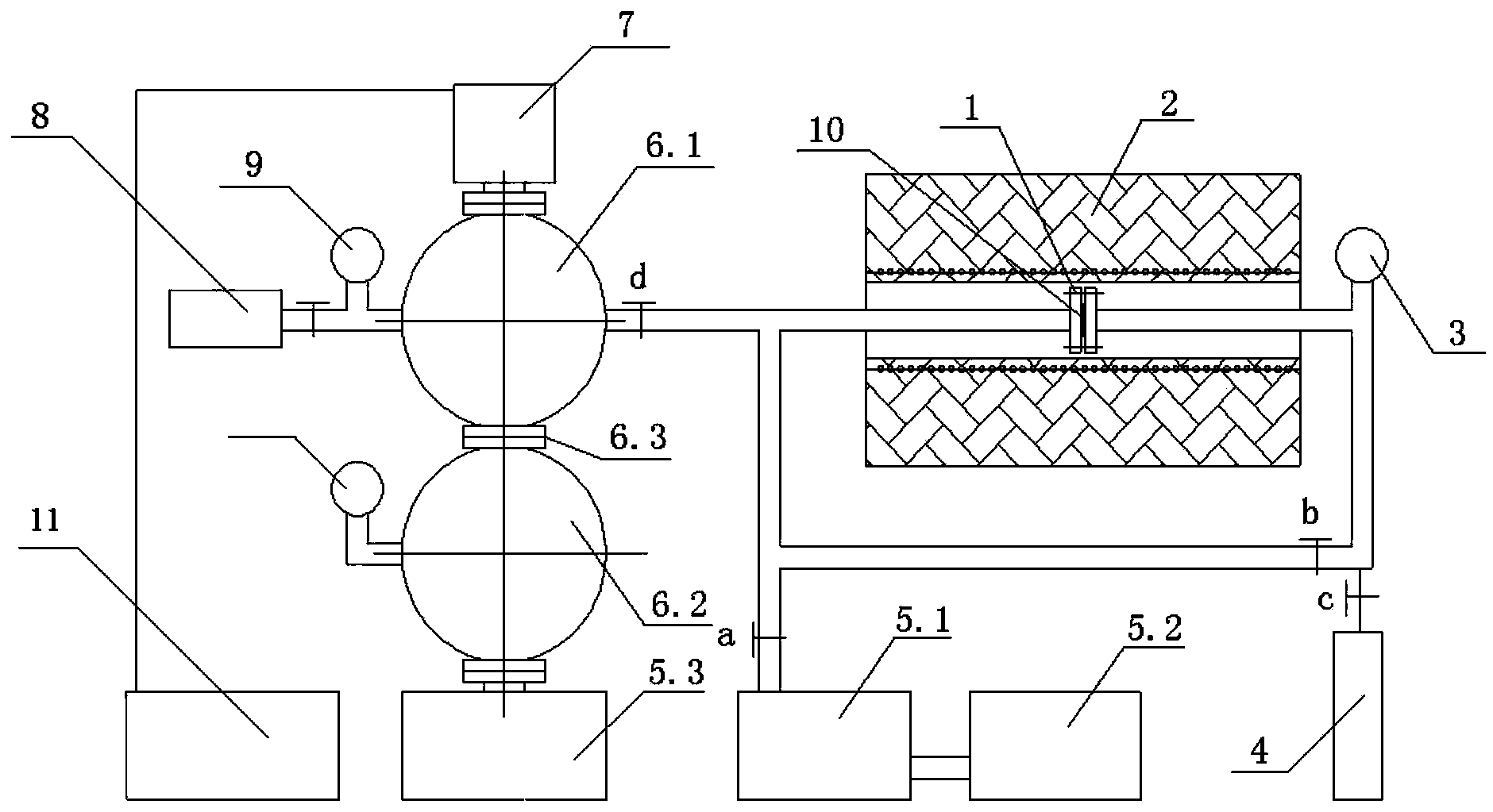

[0043] like figure 1 As shown, the device of the present invention consists of a sample chamber 1, a temperature control device 2, a pressure sensor 3, a hydrogen gas source 4, a vacuum system, a double spherical vacuum chamber, a quadrupole mass spectrometer 7, a standard hydrogen leak hole 8, a vacuum gauge 9. Composition of valves and pipelines;

[0044] There is a temperature control system 2 outside the sample chamber 1 (the temperature control system 2 in this embodiment is a temperature-controlled electric furnace), and the two ends of the sample chamber 1 are respectively connected to the molecular pump 5.1 with an oil-free mechanical pump 5.2 connected in series through pipelines, close to the molecular pump There is a valve a on the pipeline of 5.1, which is the main valve for initial vacuuming; a pressure sensor 3 and a hydrogen gas source 4 are connected to the pipeline between one end of the sample chamber 1 and the molecular pump 5.1, and the hydrogen gas source ...

Embodiment 2

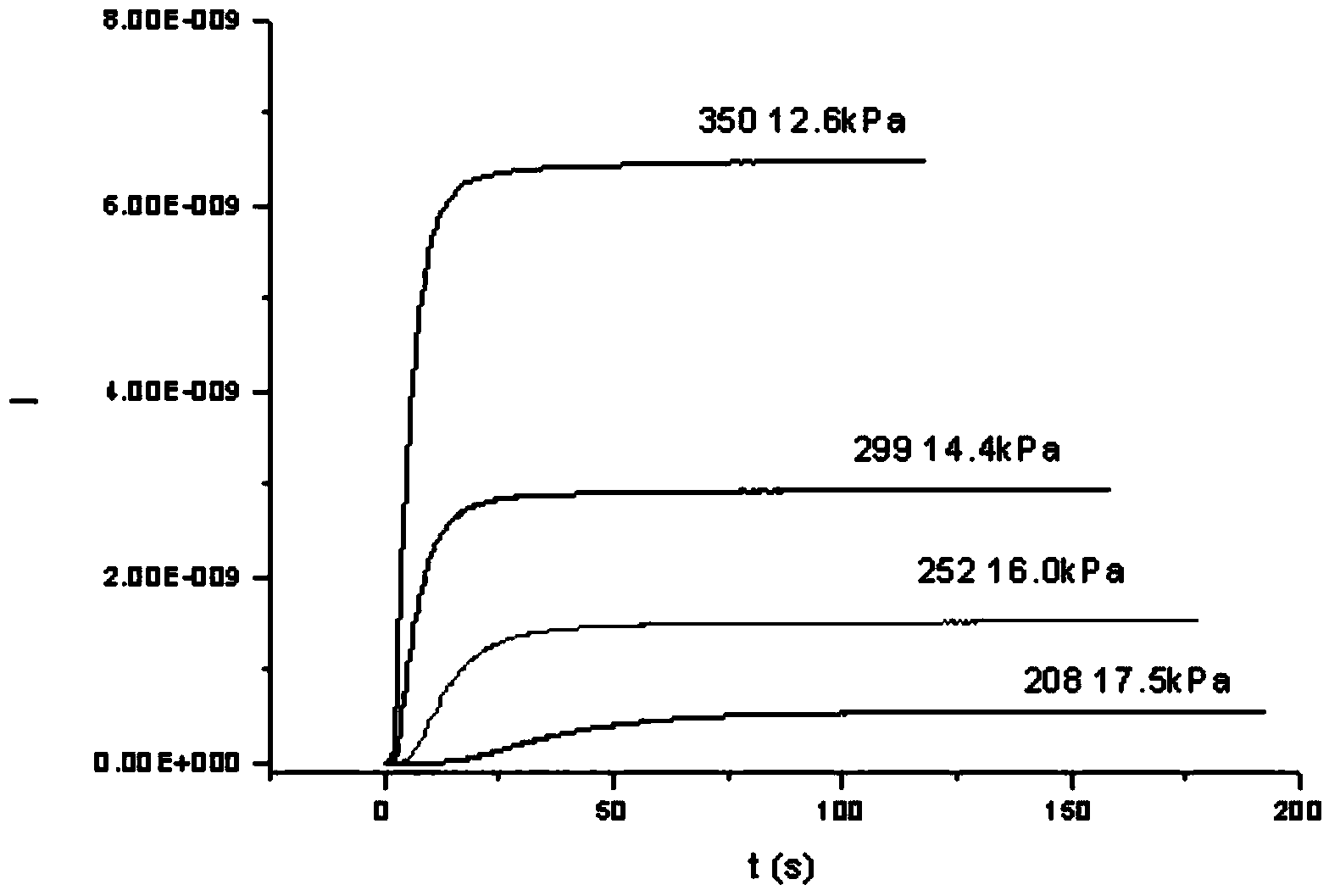

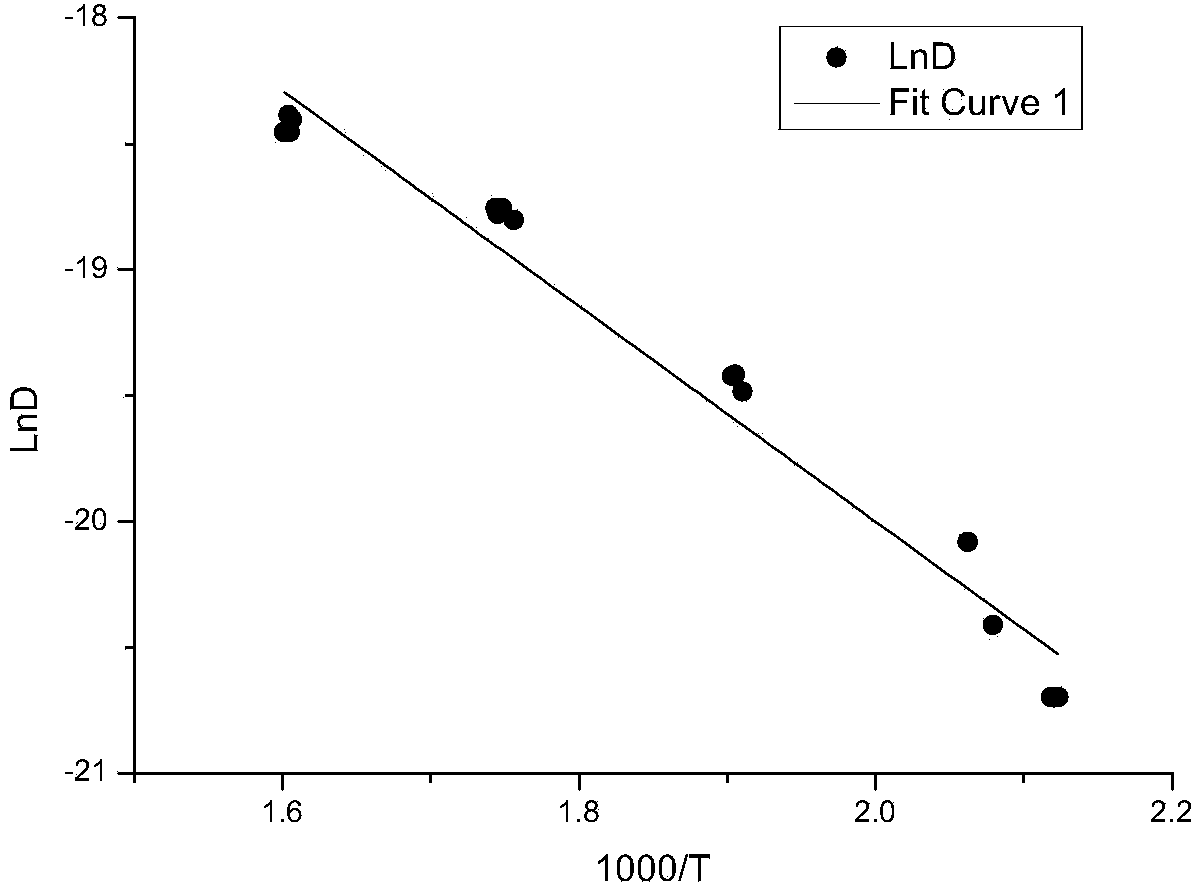

[0060] Measure the hydrogen diffusion coefficient and permeability coefficient of CLF-1 alloy (Fe-9Cr-1W) steel:

[0061] Sample: Fe-9Cr-1W alloy, thickness 0.590mm, diameter 20mm, surface mechanically polished.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com