Low-voltage electric motor protection controller and CAN bus connected multipoint remote-control device

A CAN bus and protection controller technology, applied in the field of low-voltage motor control devices, can solve problems such as inability to query motor operation data, operation status and protection faults, affecting the automation efficiency of production processes, and inability to monitor motors, so as to reduce motor burnout and Production hazard, cost reduction and maintenance cost, responsive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The structural principle of the present invention will be described in detail in conjunction with the accompanying drawings.

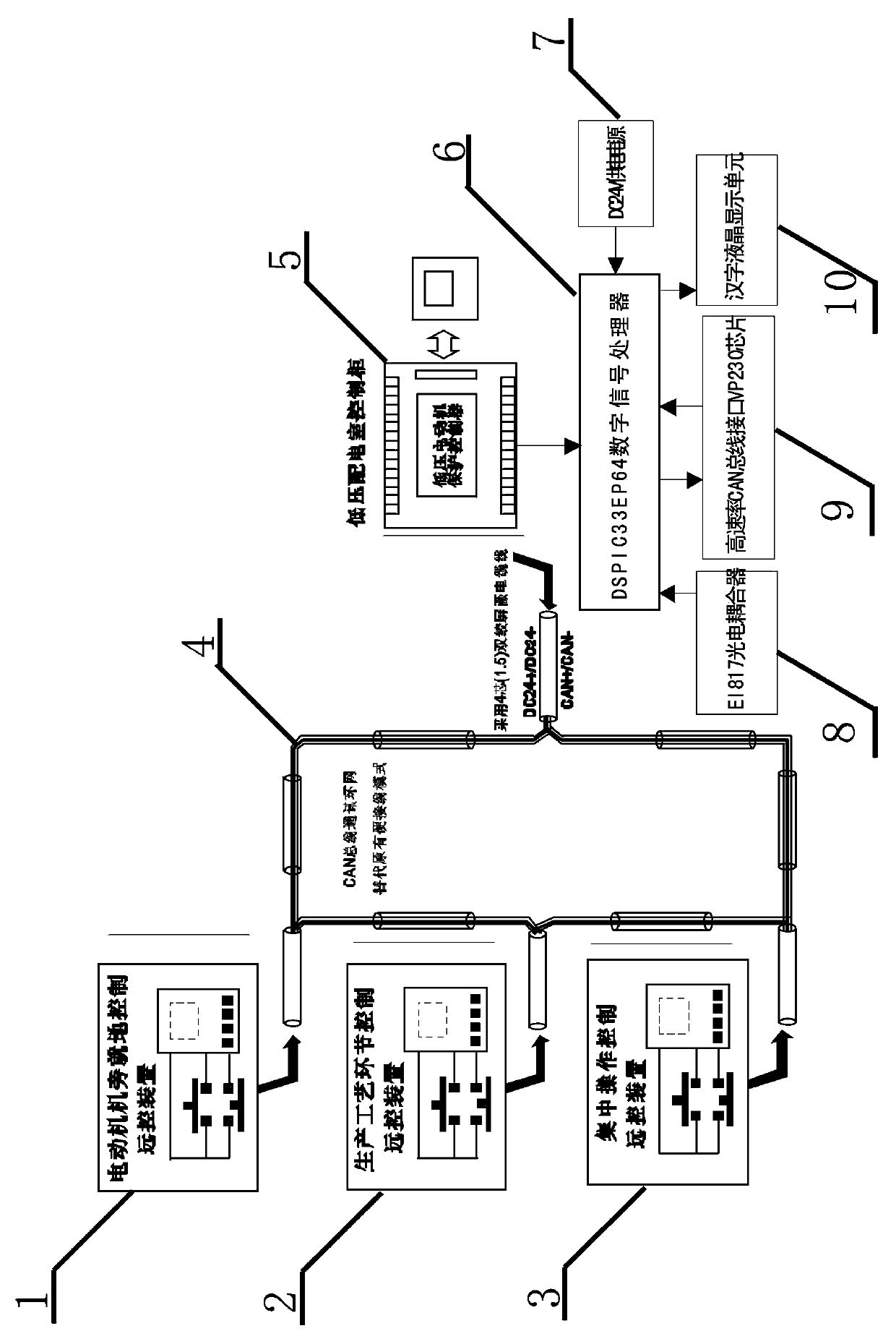

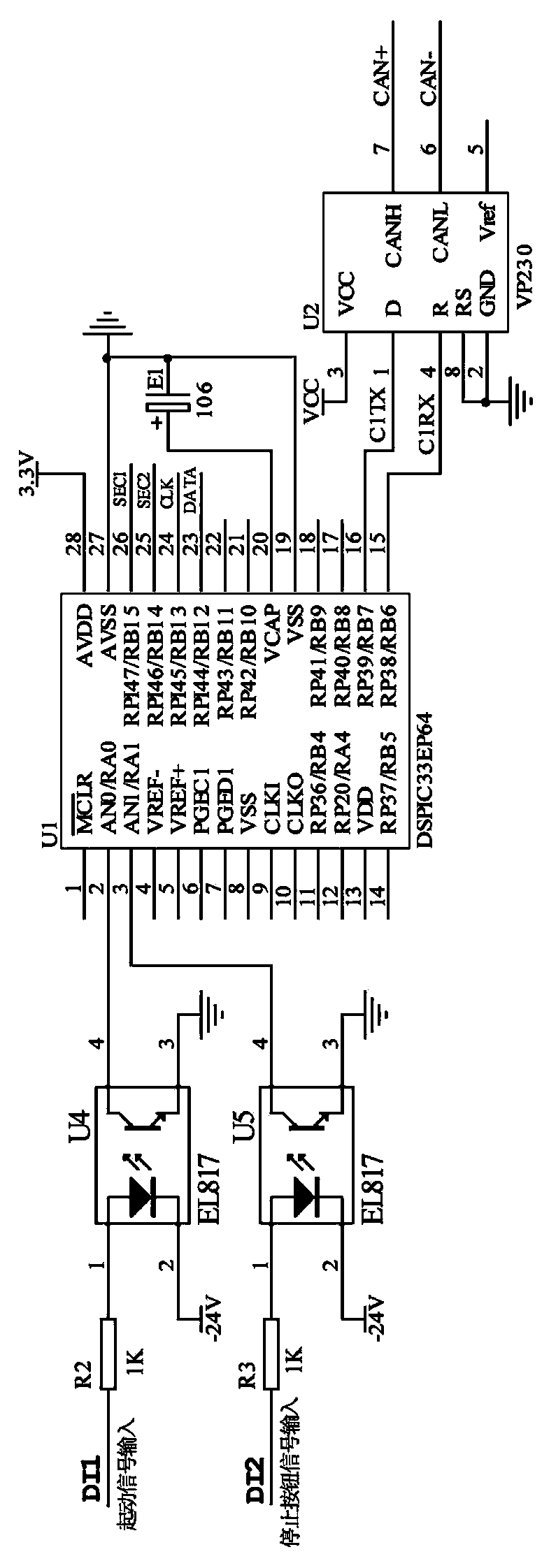

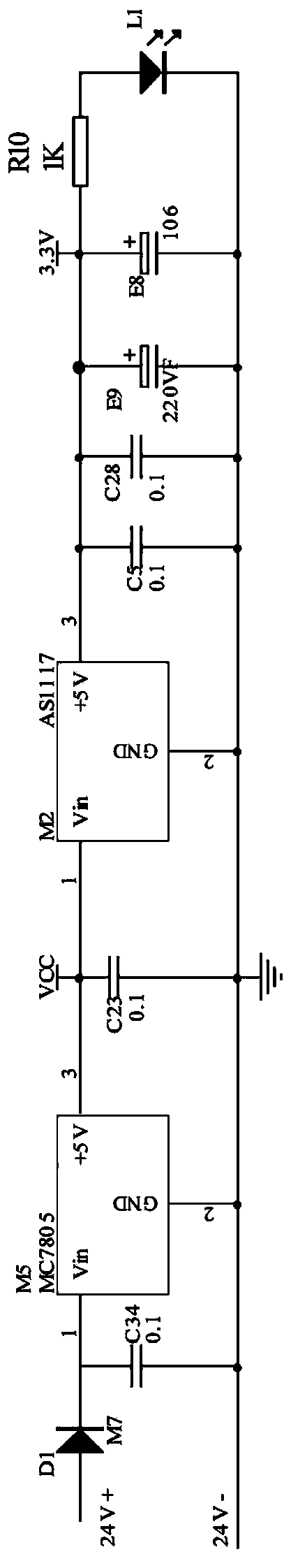

[0010] A multi-point remote control device that connects a low-voltage motor protection controller to a CAN bus, such as figure 1 As shown, through the use of CAN bus communication technology and an open communication network that conforms to global industrial standards, a cable is used to connect the low-voltage motor protection controller 5 with the local control remote device 1 next to the motor machine, and the remote control control 2 of the production process link. 1. Centralized operation control The remote control device 3 is connected to a ring CAN bus communication ring network 4 through a 4-core cable to collect data. Through the CAN bus communication ring network 4, the automation of the production process is improved. The low-voltage motor protection controller 5 receives and sends data during the operation of the CAN bus communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com