A design method for a pipeline to pass through a reverse fault with a vibration peak value of more than 0.4g

A design method and technology of reverse faulting, applied in calculation, seismic signal processing, and special data processing applications, etc., can solve problems such as large errors, different rupture angles of the surface rupture surface, different displacements in the rupture direction, and the consumption of manpower and material resources. To achieve the effect of closely linked links, good guiding significance, and smooth logic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

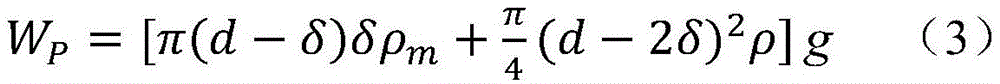

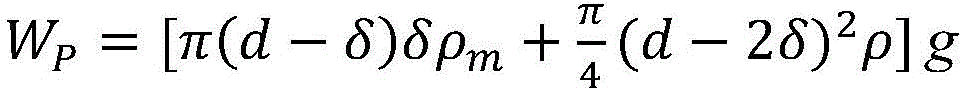

[0037] The present invention is mainly applied to how to design and install suitable pipelines when the active fault type is a reverse fault, so that the pipeline in the reverse fault has good anti-seismic performance. The present invention is especially designed for reverse faults with a vibration peak value above 0.4g, and the design process includes the following steps:

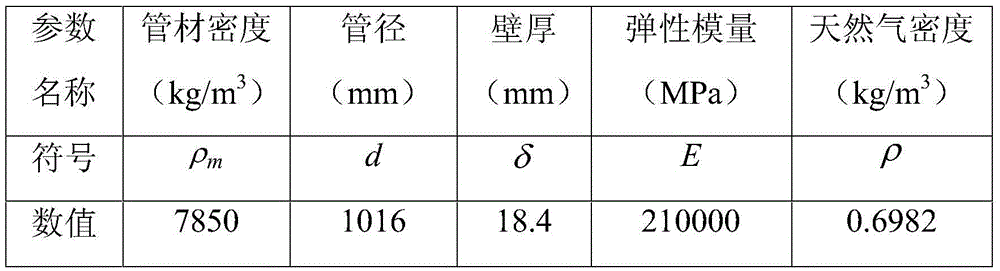

[0038] (1) Select the reverse fault, and arbitrarily select the pipeline to be installed in the reverse fault, and measure and record the parameters of the pipeline at the same time, the parameters include the pipe density ρ m , pipe diameter d, wall thickness δ and elastic modulus E; the parameters in this step can be measured by existing technical means;

[0039] (2) Measure the fault dip angle α of the reverse fault, and calculate the surface vertical dislocation D of the reverse fault respectively CV and surface level dislocation D CH ; The fault dip angle α in this step is also obtained by using the e...

example 1

[0058] For the reverse fault in the test, the covering soil layer thickness H is 0m (that is, the bedrock), the Richter magnitude M is simulated as 7.0, and the soil quality is clay.

[0059] The basic parameters of the reverse fault are shown in Table 2:

[0060]

[0061] Table 2

[0062] (1) Calculate the surface vertical dislocation D of the reverse fault CV :lnD CV =0.926×7.0-0.028×0+1.305×sin60°-7.192=0.42m, calculated as D CV =1.522m; calculate the surface horizontal dislocation D of the reverse fault CH :lnD CH =0.926×7.0-0.085×0-0.861×sin60°-5.573=0.163m, calculated as D CH =1.177m;

[0063] (2) The intersection angle β between the design pipeline and the fault is 30°, then the fault displacement parallel to the axis of the pipeline ΔX=D CH cosβ=1.177×cos30°=1.019m, the fault displacement ΔY=D in the normal direction of the pipeline CH sinβ=1.177×sin30°=0.589m;

[0064] (3) Calculation of the critical compressive stress σ when the pipeline is destabilized b...

example 2

[0077] The above parameters are still used, and the difference from Example 1 is that in this example, the covering soil layer thickness H is 15m, the Richter magnitude M is simulated as 7.2, and the reduction factor η is 4, then:

[0078] (1) Calculate the surface vertical dislocation D of the reverse fault CV:lnD CV =0.926×7.2-0.028×15+1.305×sin60°-7.192=0.185m, calculated as D CV =1.203m; Calculate the surface horizontal dislocation D of the reverse fault CH :lnD CH =0.926×7.2-0.085×15-0.861×sin60°-5.573=-0.926m, calculated as D CH =0.396m;

[0079] (2) Fault displacement parallel to the pipeline axis ΔX=D CH cosβ=0.396×cos30°=0.343m, the fault displacement ΔY=D in the normal direction of the pipeline CH sinβ=0.396×sin30°=0.198m;

[0080] (3) Calculation of the critical compressive stress σ when the pipeline is destabilized by compression c =555×10 6 pa;

[0081] (4) Calculate the friction force f per unit length of the pipeline s =6.169×10 4 N / m;

[0082] (5) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com