Double-layer super-junction Schottky diode

A diode and double-layer technology, applied in the field of double-layer superjunction Schottky diodes, can solve the problems of poor charge balance dynamic characteristics of superjunction power Schottky diodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

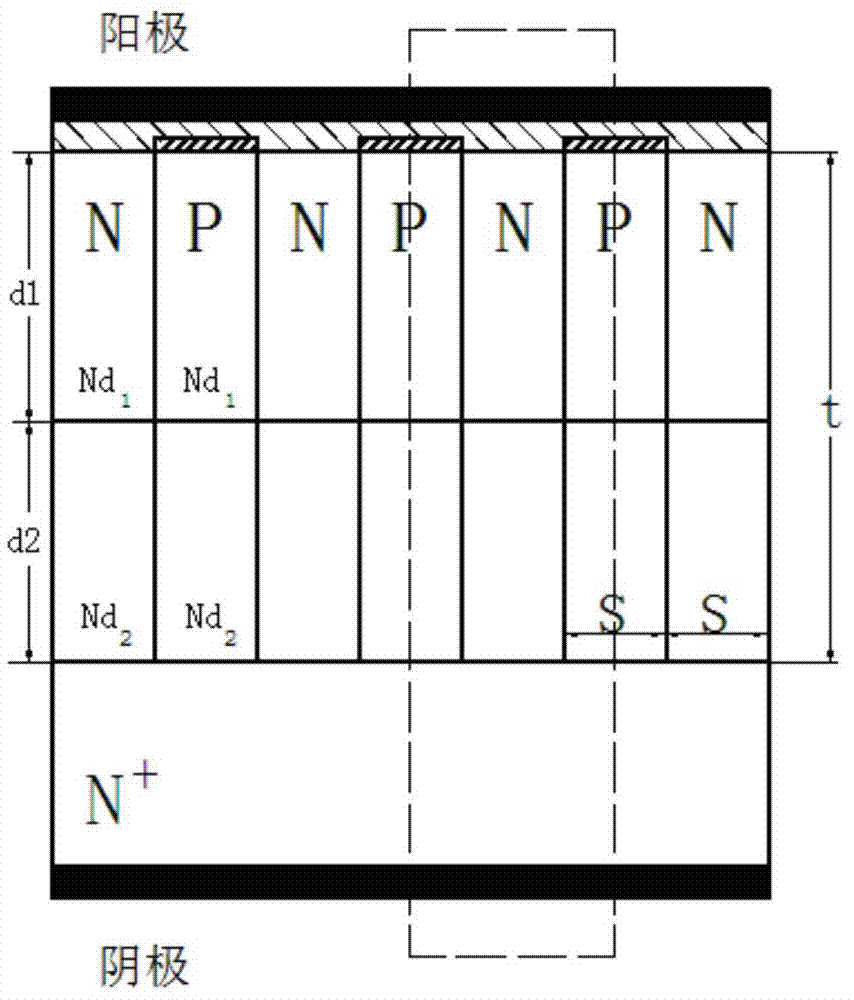

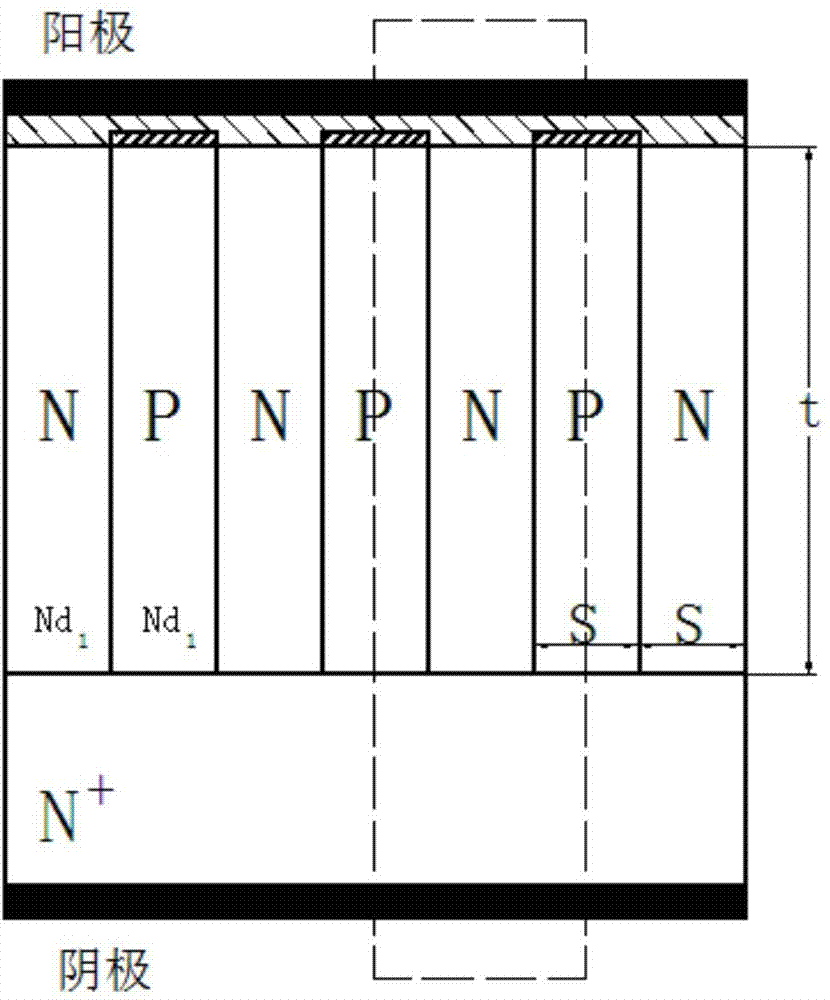

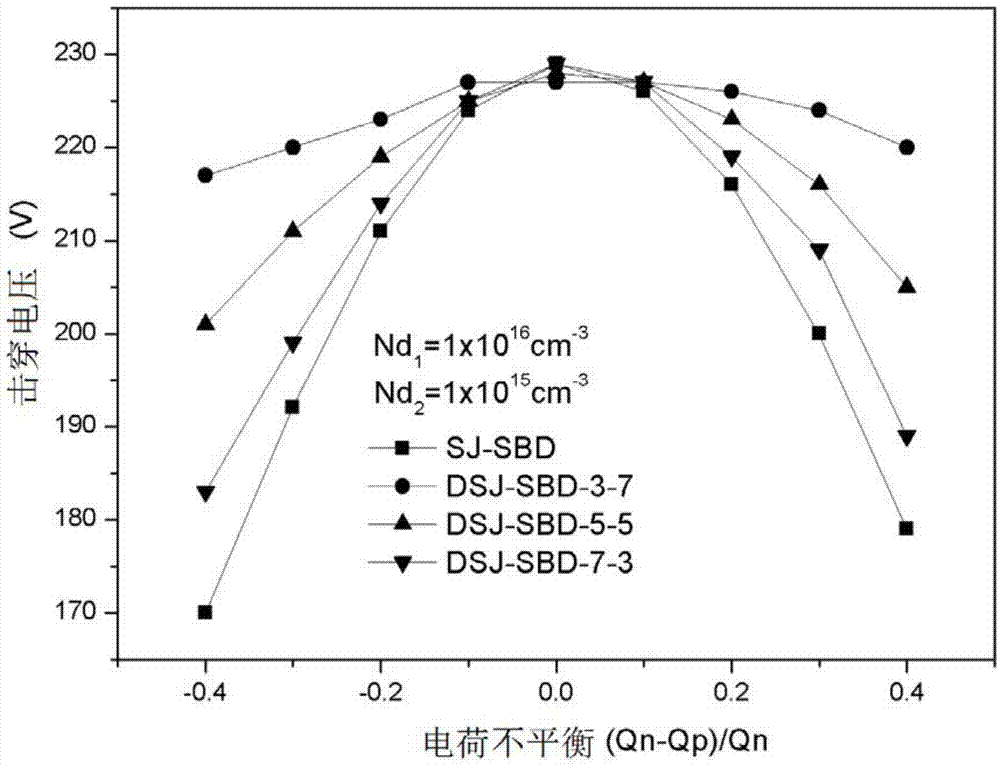

[0024] The technical solution of the embodiment of the present invention mainly includes: the drift region of the power Schottky device adopts a double-layer super junction structure, wherein the N column forms a Schottky contact with the metal anode, and the P column forms an ohmic contact with the metal anode. Wherein, the upper and lower double-layer superjunctions have the same width. The doping concentration of the upper superjunction is higher than that of the lower superjunction, and the depth and doping concentration of the upper and lower double-layer superjunctions are set in combination with the technical indicators of the actual power Schottky device.

[0025] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0026] refer to figure 1 , the basic structure of the double-layer super junction Schottky diode (DSJ-SBD) of the present invention. DSJ-SBD adopts a double-layer superjunction structure, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com