Motor damping vibration attenuation structure

A vibration reduction structure and damping technology, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of increasing the amount of materials and reducing the vibration effect of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

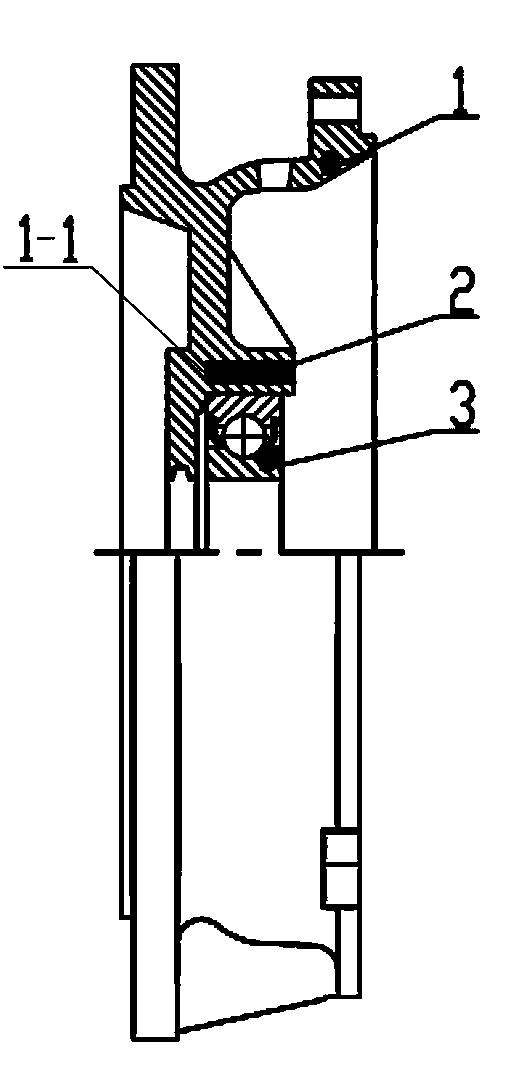

[0018] The motor damping vibration reduction structure of the present invention, including motor bearing 3, end cover 1, and damping ring 2. Among them, a loop groove 1-1 corresponding to the outer ring with the outer ring of the motor bearing 3 on the end cover 1 isThe section depth of the circular groove 1-1 is 2mm larger than that of the motor bearing 3 in the outer ring, and the cross-section width is set to 5mm.The damping ring 2 is installed in the ring groove 1-1 and adopts a proficiency.The damping ring 2 uses fluorine rubber parts, and its loss factor is 0.11. After comparison testing, the motor is made by the motor of the existing technology. The vibration acceleration level of the motor is 105DB.The acceleration test results are 100dB, which reduces 5DB.

Embodiment 2

[0020] The motor damping vibration reduction structure of this embodiment is basically the same as the embodiment 1. The difference is that the section depth of the ring groove 1-1 is 5mm larger than the outer width of the motor bearing 3, and the section width is 10mm;The mixture of silicon oil and metal particles is installed in the plastic pipe fittings that are adapted to the ring groove 1-1. The weight ratio of the silicon oil and metal particles in the mixture products is 1: 0.3. Among them, the metal particles are lead leadersThree kinds of mixed pills of pills, steel pills and aluminum pills. The mixing pills are based on the weight ratio: Lead Pill: Steel Pill: Aluminum Pill = 1: 1, the particle size of metal particles is 0.4 mm, silicone oilSelect the viscosity to 5000mm 2 / s (25 ° C) methyl silicon oil, the loss factor of 0.15.After comparison testing, the motor is made by the motor of the existing technology. The vibration acceleration level of the motor is 105 dB. Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com