Method for temperature compensation in sensor, computation program for method for temperature compensation, computation processing device, and sensor

A temperature compensation and sensor technology, applied in the temperature compensation of the sensor, the calculation program of the temperature compensation, the calculation processing device, and the field of sensors, can solve the problems of difficult diaphragm thinning, increase pressure sensitivity, etc., and achieve high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach >

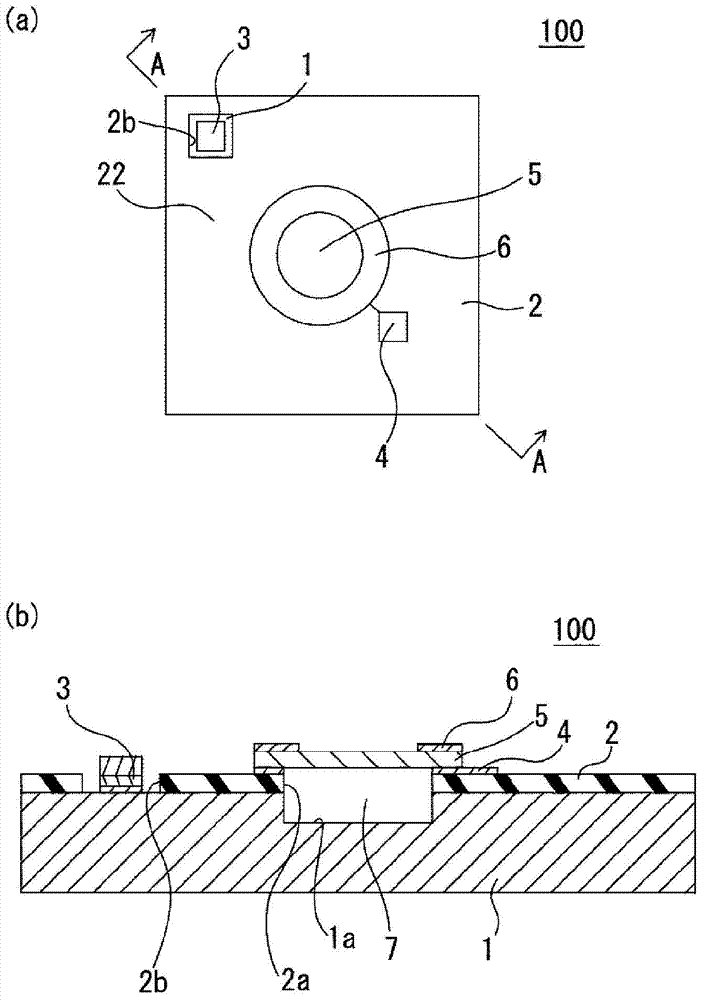

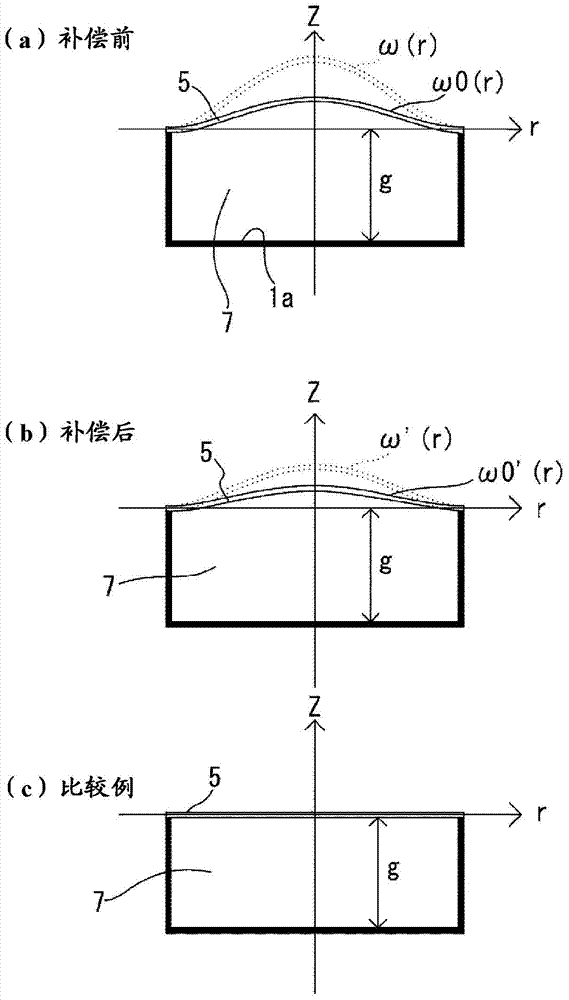

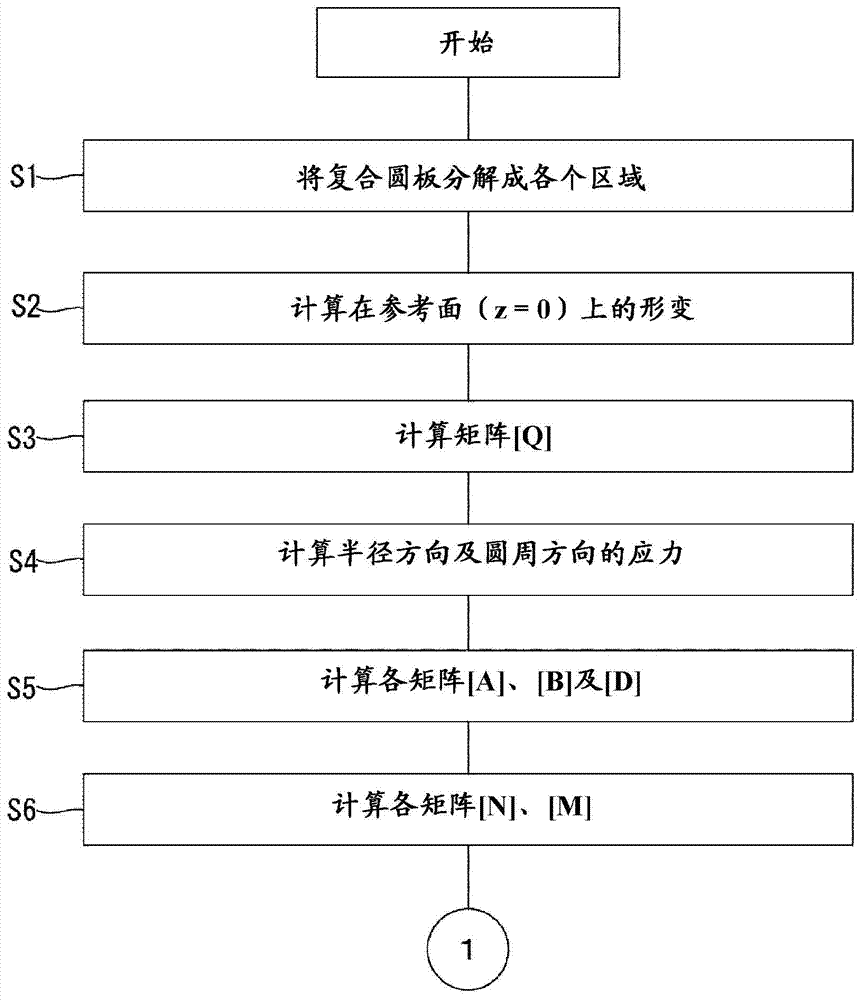

[0149] Below, refer to Figure 1-Figure 6 , the temperature compensation method of the sensor according to the first embodiment of the present invention will be described.

[0150] (Structure of Capacitive Sensor 100 )

[0151] Such as figure 1 As shown in (a) and (b), the capacitance type sensor (sensor) 100 to which the calculation result of the temperature compensation method of the capacitance type sensor is applied includes a substrate 1 , an insulator layer 2 , a first electrode portion 3 , and a second electrode portion (conductive part) 4 , diaphragm part 5 , temperature compensation ring (temperature compensation member) 6 , and sealed space 7 .

[0152] The substrate 1 is made of a semiconductor such as silicon, and has a circular concave portion 1 a in a substantially central portion.

[0153] The insulator layer 2 is a layer made of an insulator such as silicon dioxide, and is formed on one surface of the substrate 1 . In addition, the insulator layer 2 has a cir...

no. 2 approach >

[0195] Next, use Figure 7-Figure 10 , the temperature compensation method of the sensor according to the second embodiment of the present invention will be described. In addition, since the positions 1-7 of the capacitance sensor 100 to which the calculation result of the temperature compensation method of the first embodiment is applied and the positions 21-27 of the capacitance sensor 200 to which the calculation result of the temperature compensation method of the present embodiment are applied (Some parts are not shown) are the same parts in order, so the description may be omitted.

[0196] (Structure of Capacitive Sensor 200 )

[0197] Such as Figure 7 As shown, the capacitive sensor (sensor) 200 includes the same substrate 21, insulator layer 22, first electrode part 23, second electrode part (conductive part) 24, diaphragm part 25, temperature The compensation ring (temperature compensation member) 26 , the closed space 27 , and a first barrier metal layer 28 are ...

no. 3 approach >

[0205] Next, use Figure 11-Figure 14 , the temperature compensation method of the sensor according to the third embodiment of the present invention will be described. In addition, since the positions 1-7 of the capacitance sensor 100 to which the calculation result of the temperature compensation method of the first embodiment is applied and the positions 31-37 of the capacitance sensor 300 to which the calculation result of the temperature compensation method of the present embodiment are applied (Some parts are not shown) are the same parts in order, so the description may be omitted.

[0206] (Structure of Capacitive Sensor 300 )

[0207] Such as Figure 11 As shown, the capacitive sensor (sensor) 300 has the same substrate 31 as the above-mentioned capacitive sensor 100, an insulator layer 32, a first electrode part 33, a second electrode part 34, a diaphragm part 35, a temperature compensation ring (temperature compensating member) 36 , a closed space 37 , and a seal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com