Technological rolling lubricating system of finish rolling mill for hot-rolled strip steel

A lubrication system and hot-rolled strip technology, applied in metal rolling, metal rolling, rolls, etc., can solve problems such as unstable roll shape and size control, product surface quality degradation, and increased stress conditions , to achieve the effect of stable pattern and size control, improved pickling capacity, and reduced stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

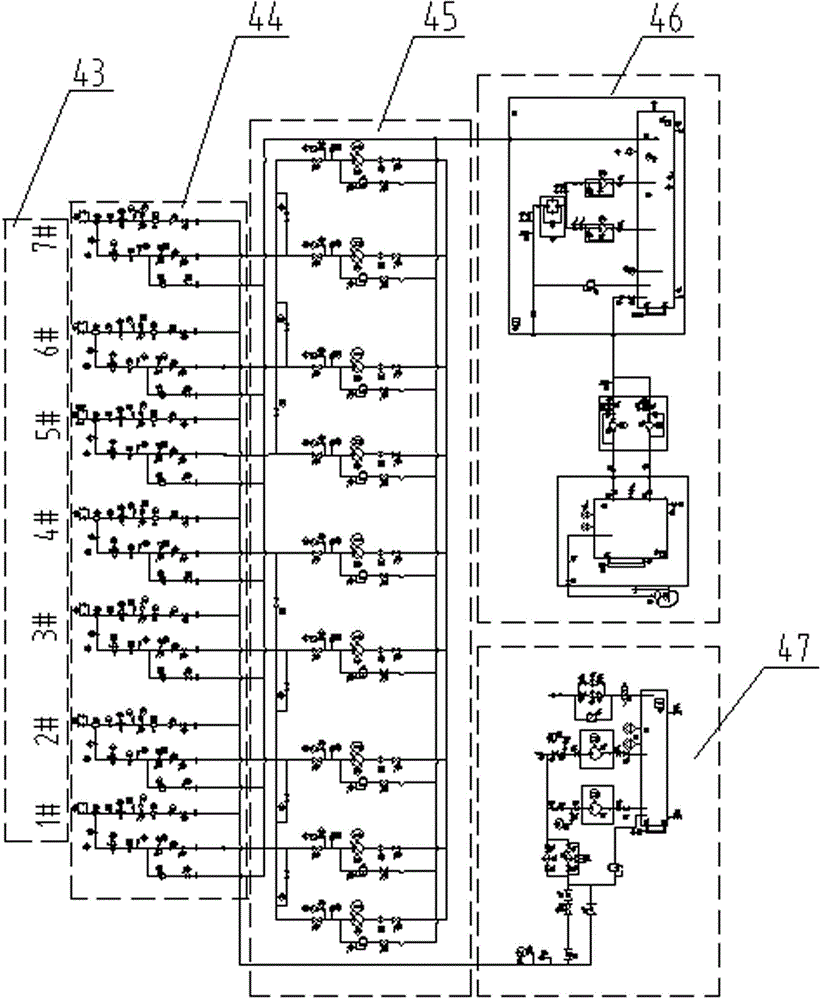

[0021] Such as figure 1 As shown, the hot-rolled strip finishing mill process rolling lubrication system includes a water supply device 47, an oil supply device 46 and a metering pump station 45, and the oil supply device 46 passes through the working oil pump 13 on the device and the oil inlet 28 of the metering pump station Connection, the water supply device 47 is connected to the water inlet 31 of the oil-water mixing control unit 44, the metering pump station 45 is connected to the oil inlet 30 of the oil-water mixing control unit 44, and the oil-water mixing control unit 44 is connected to the lubricating header 43.

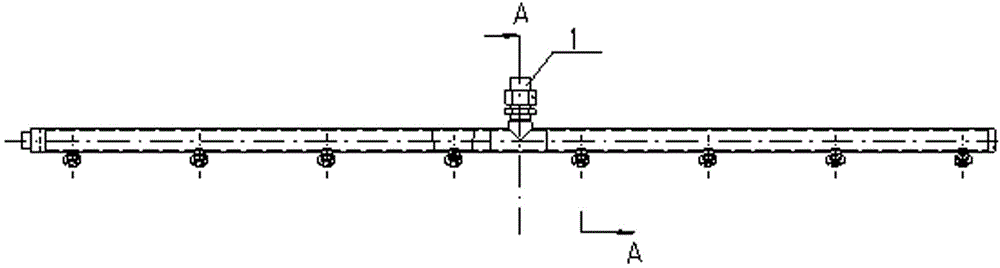

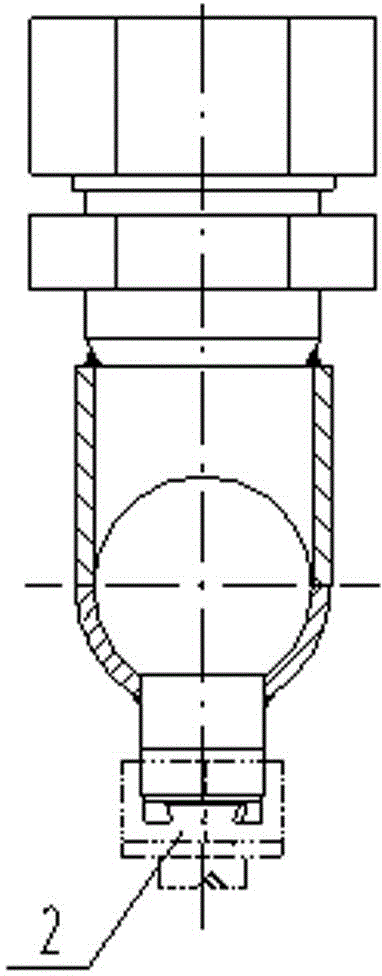

[0022] Such as figure 2 , image 3 As shown, the lubricating manifold 43 includes a mixed fluid inlet 1 and a nozzle 2, the mixed fluid inlet 1 is connected to the oil-water mixing control unit, and the lubricated manifold 43 is equipped with a nozzle 2, and the spray angle of the nozzle 2 is 4-10°.

[0023] Such as Figure 4 , Figure 5 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com