Patents

Literature

41results about How to "Suppress spawn rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

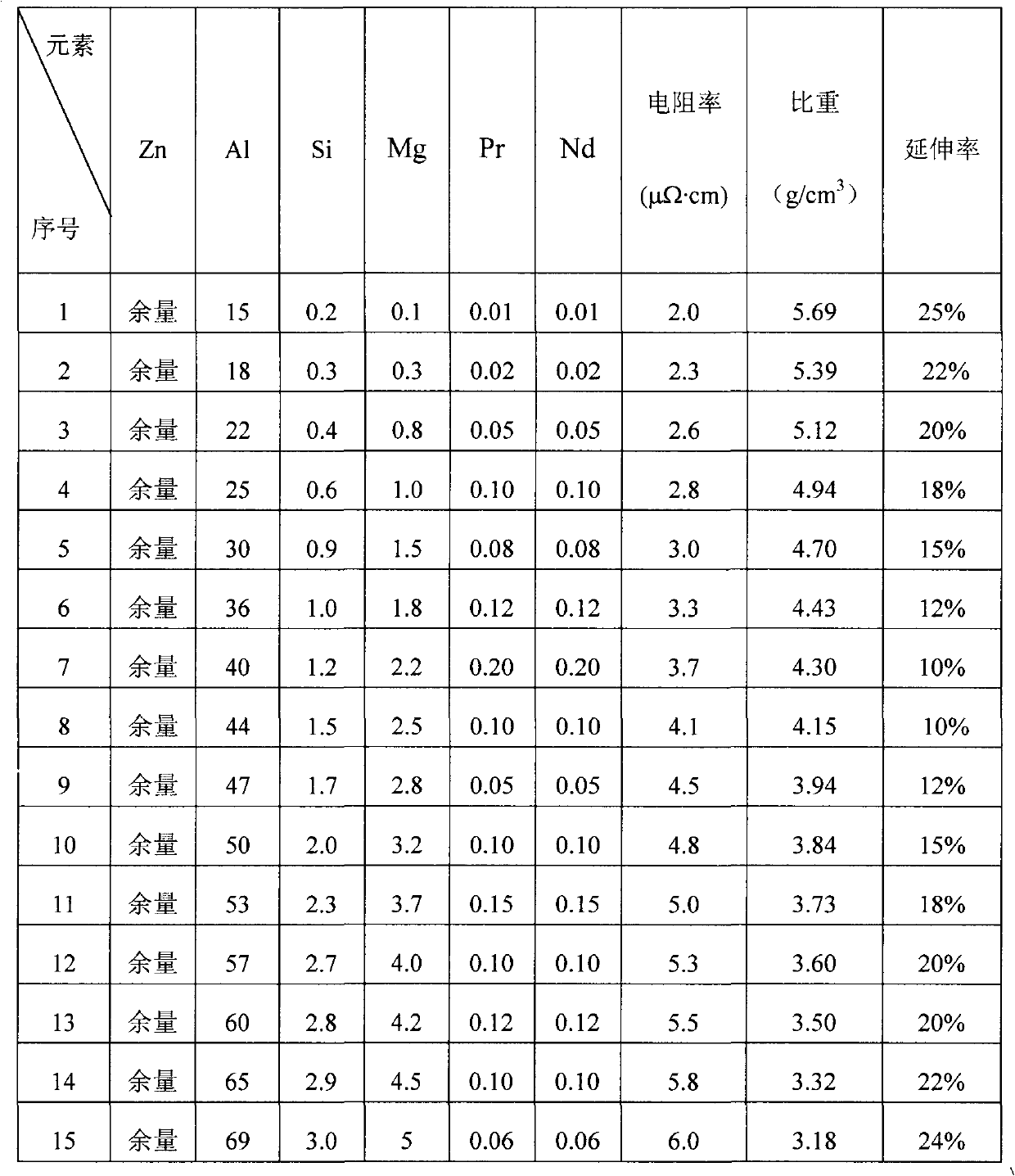

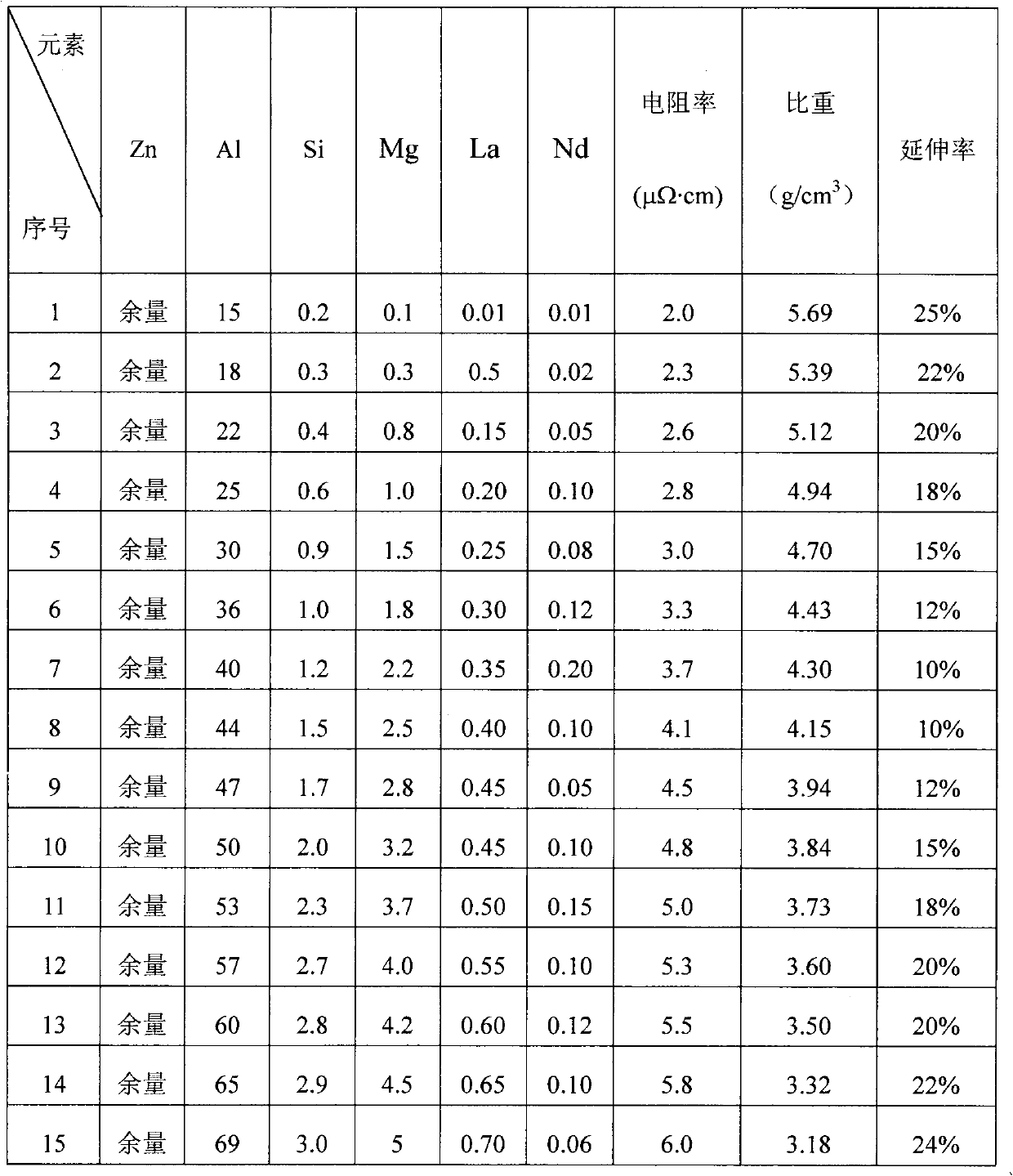

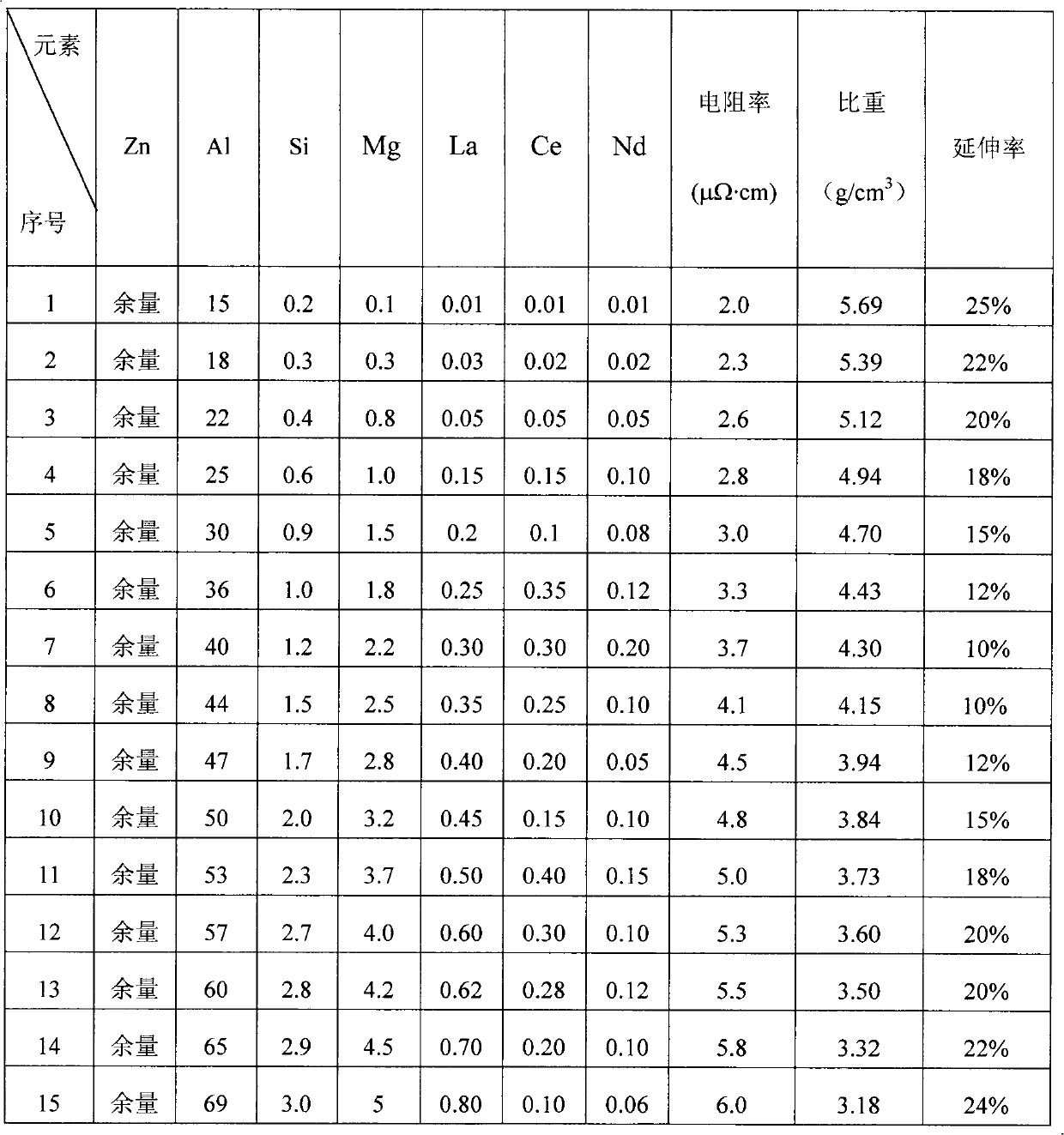

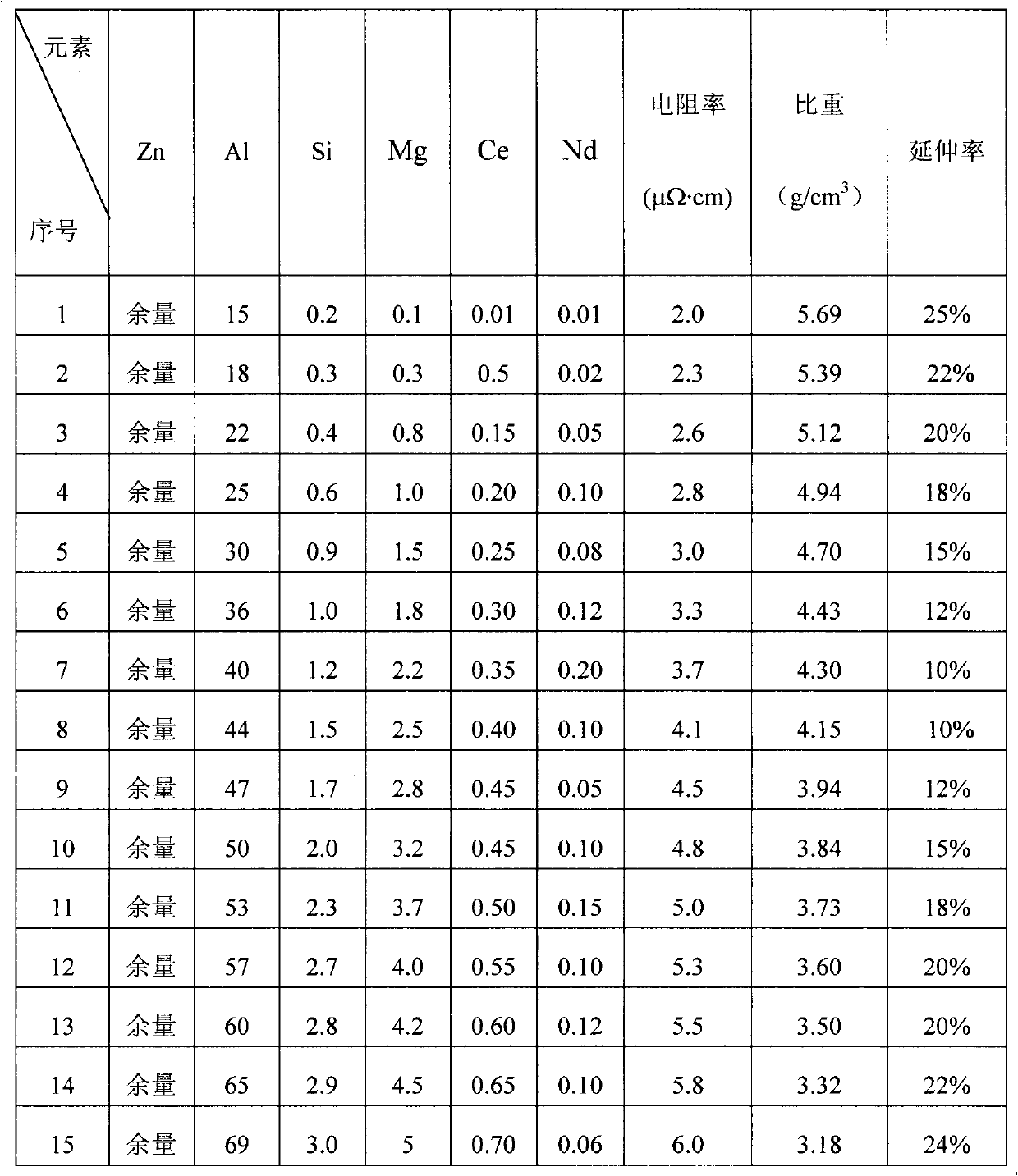

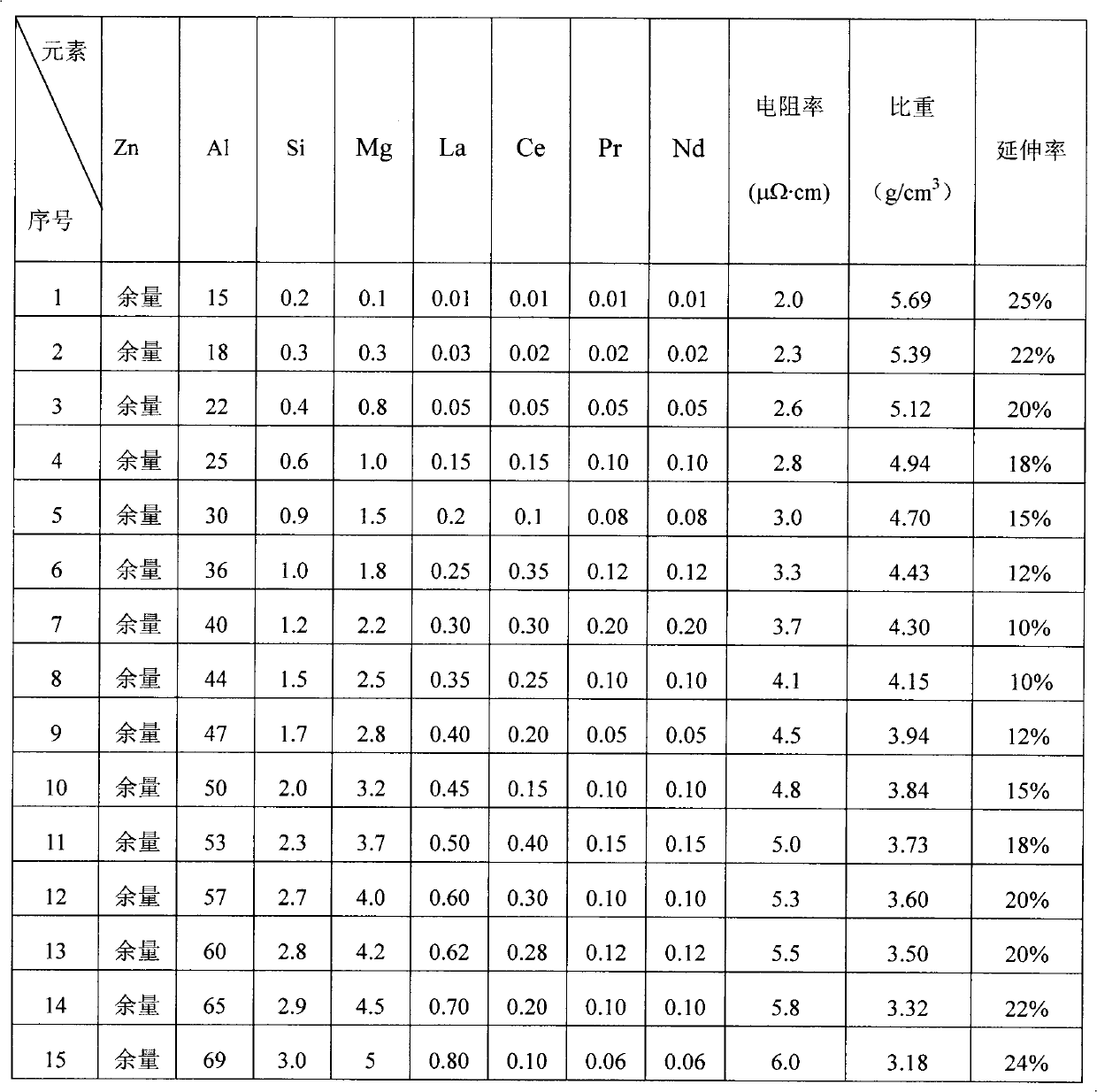

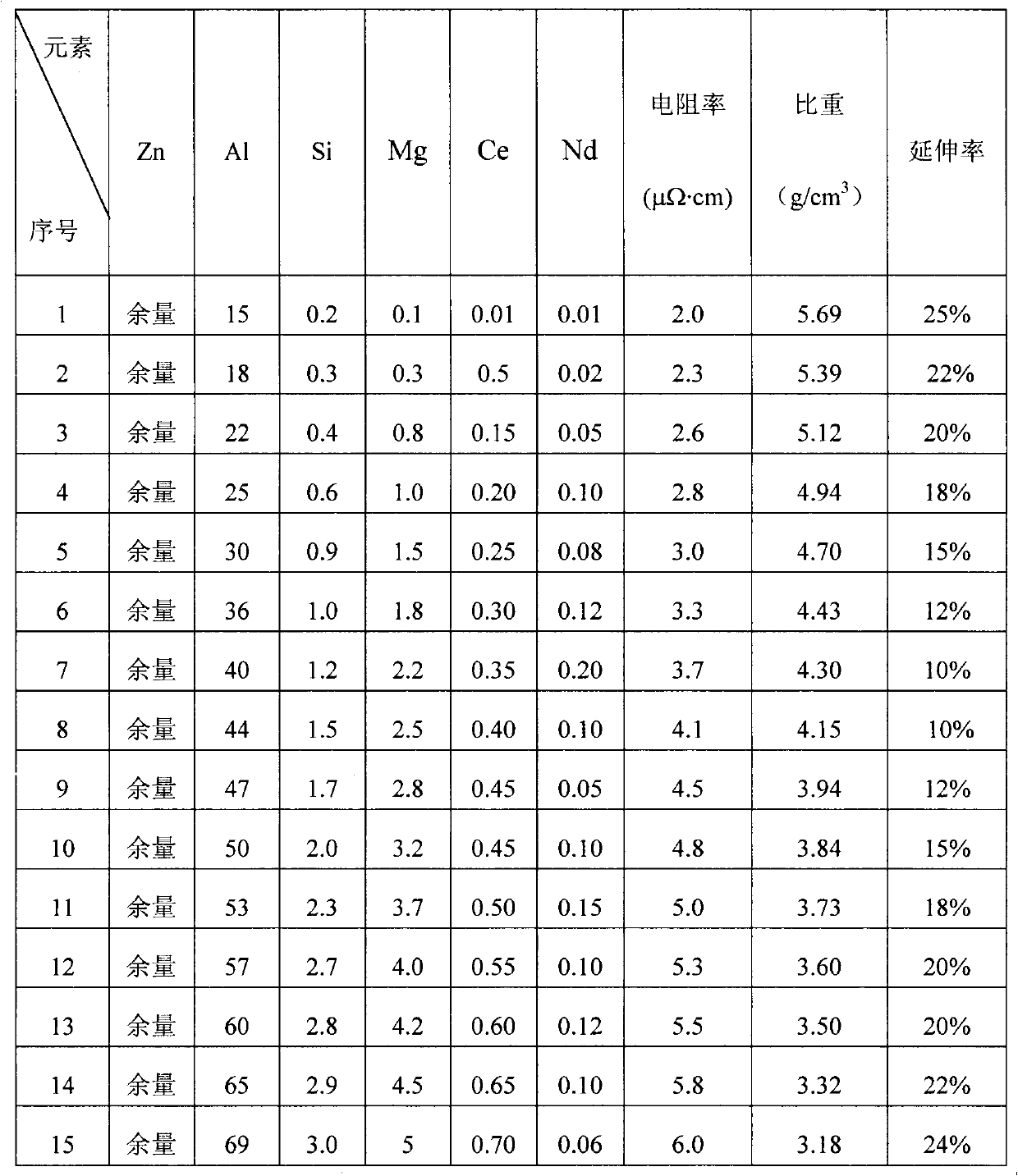

Multielement zinc-aluminum alloy wire and manufacturing method thereof

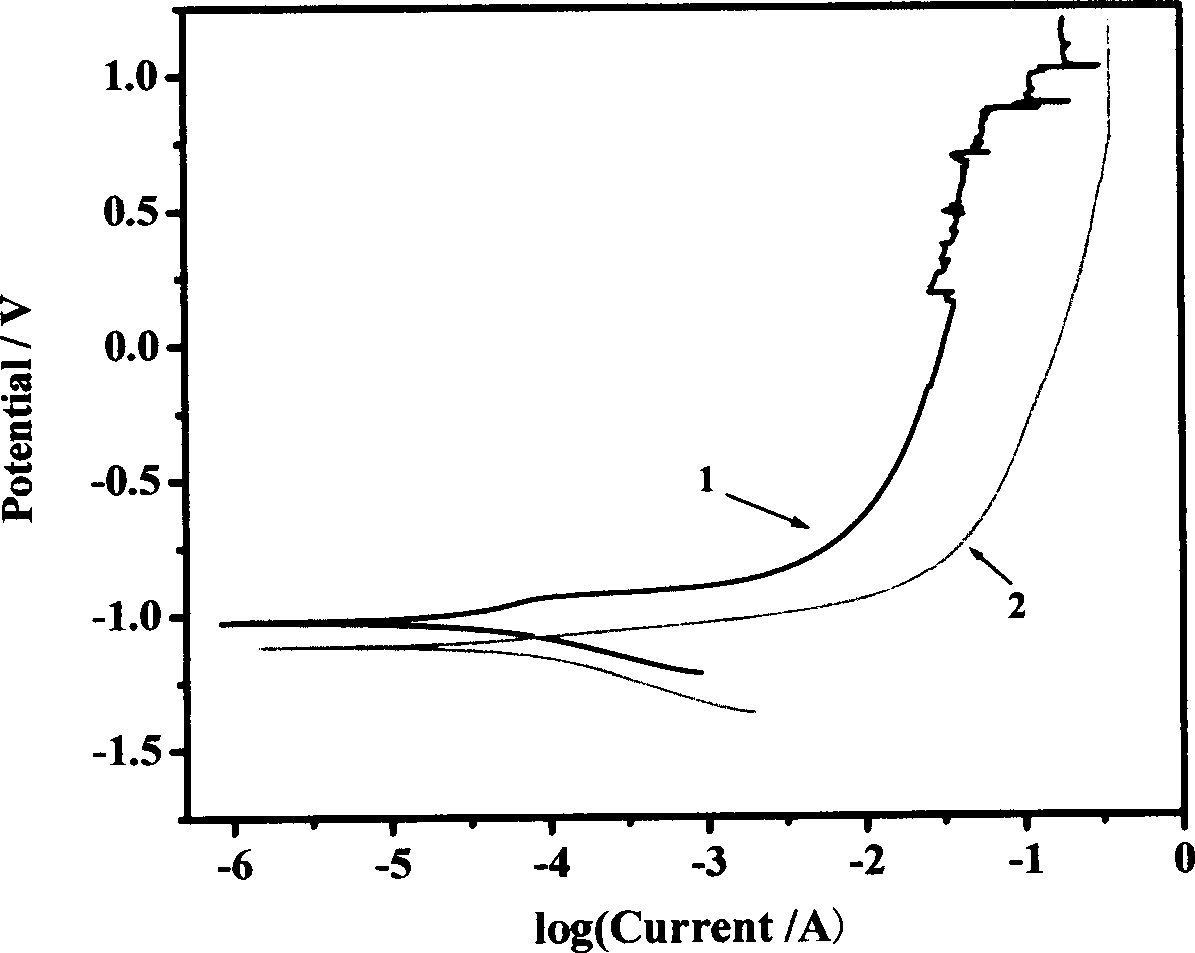

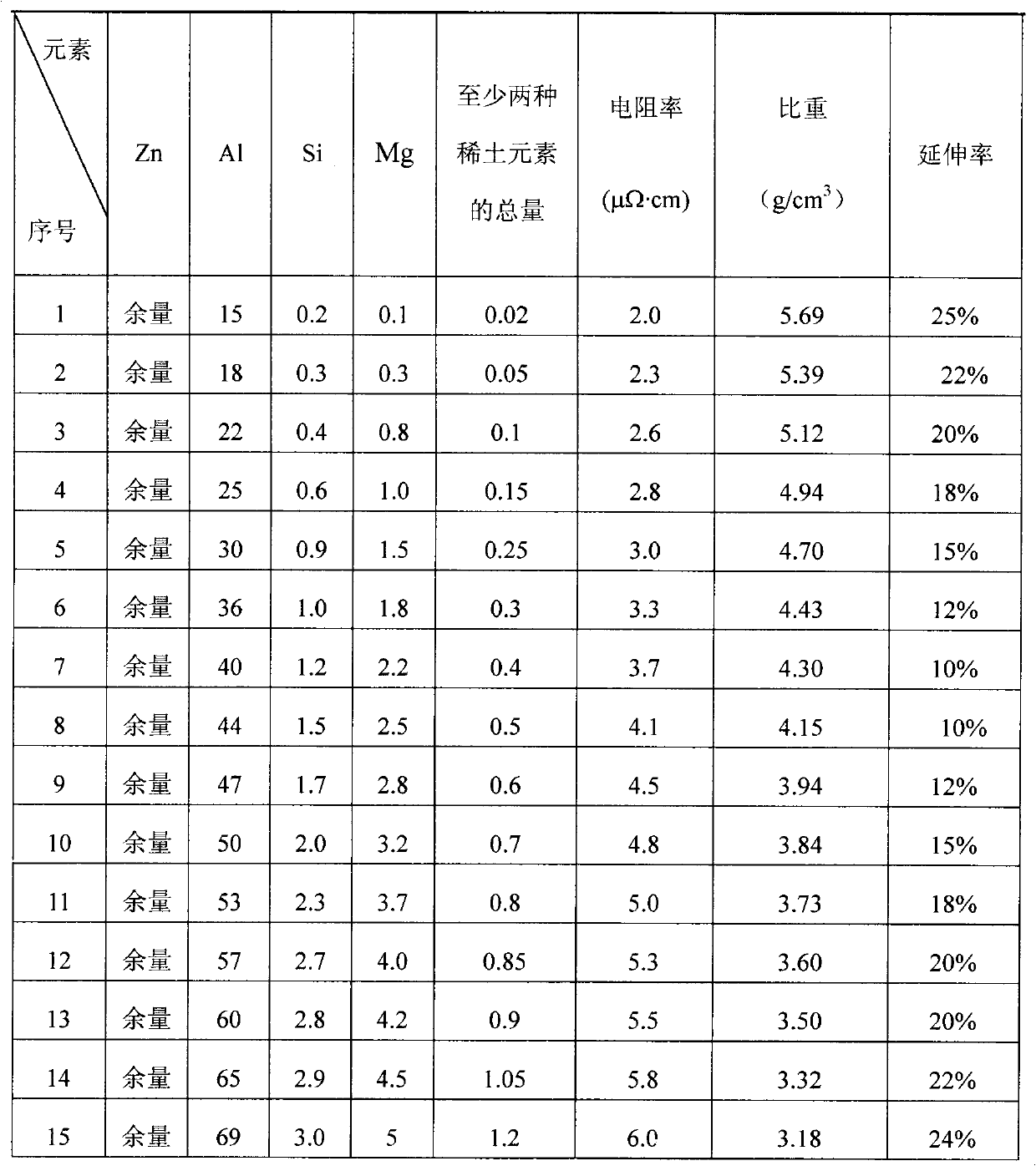

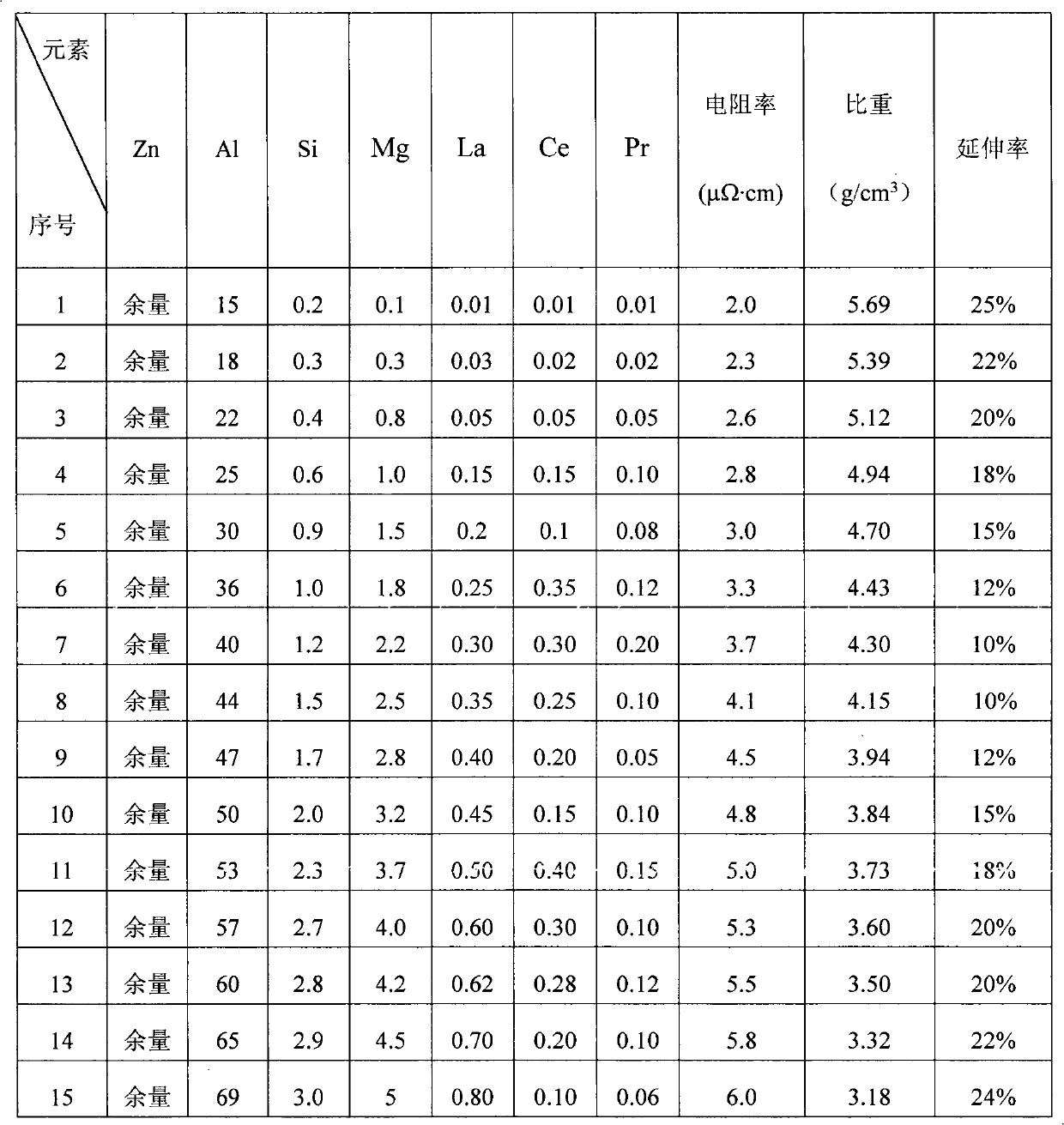

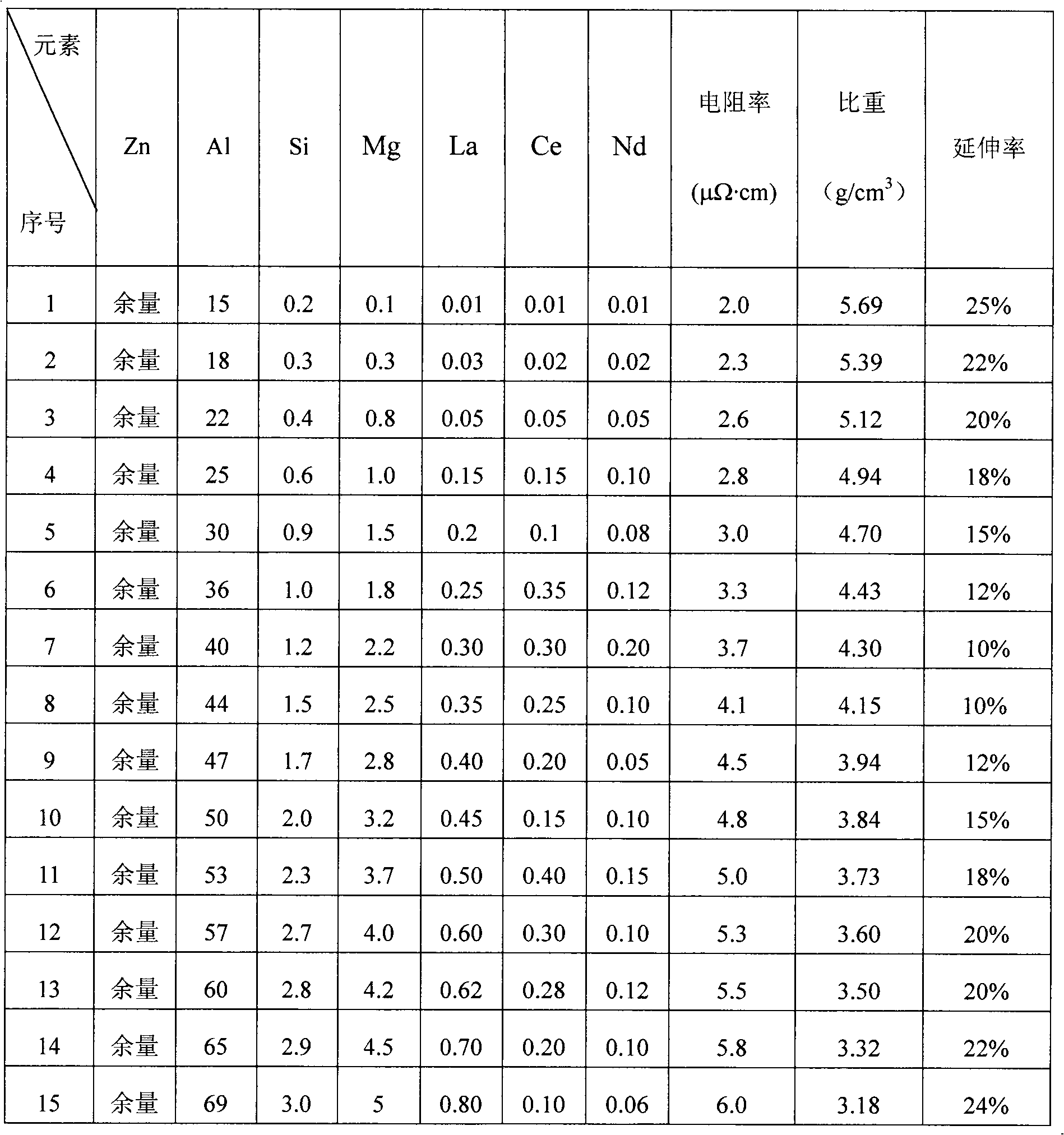

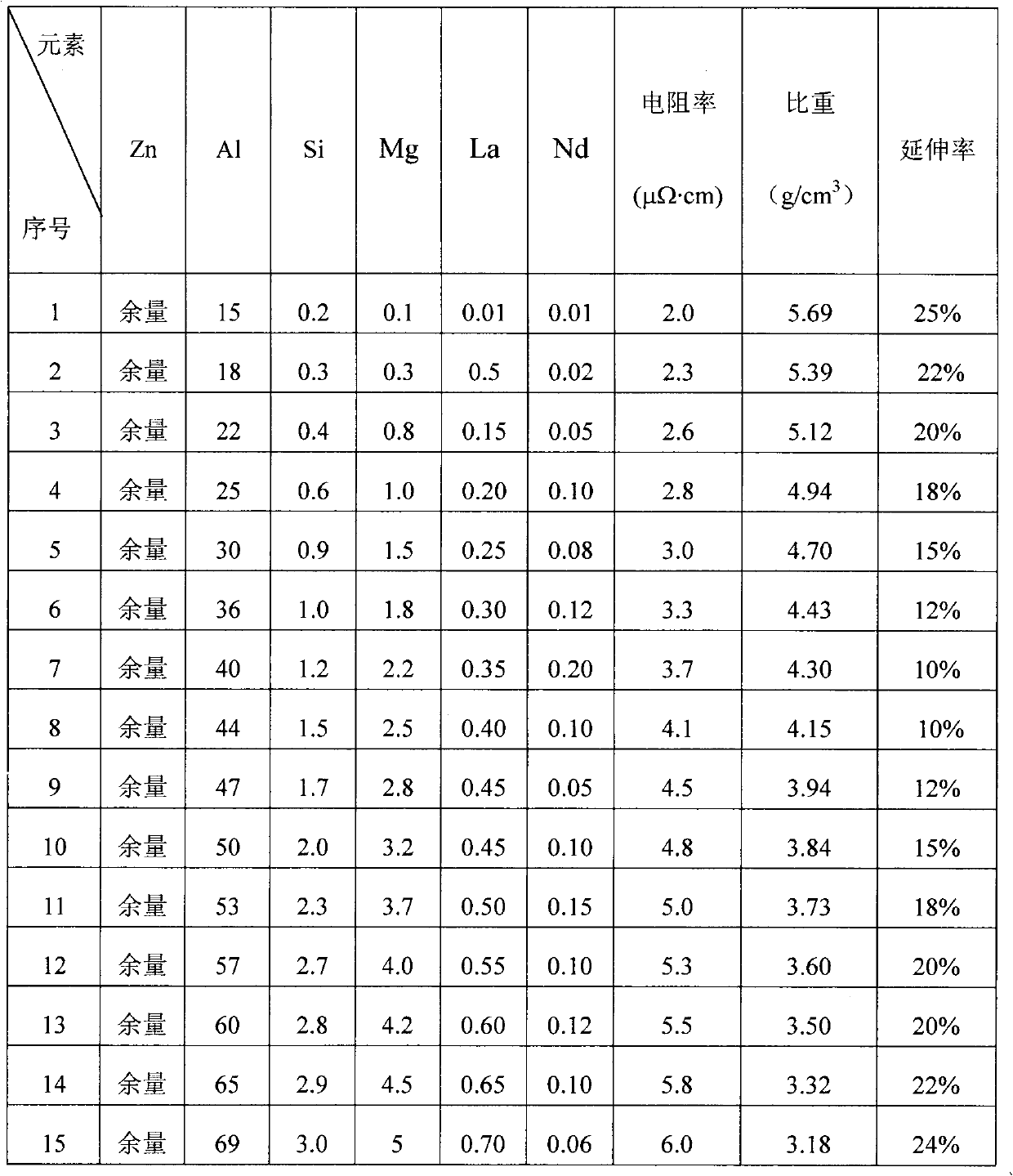

The invention relates to a multielement zinc-aluminum alloy wire which comprises the following components in percentage by weight: 15-69% of Al, 0.2-3% of Si, 0.1-5% of Mg, 0.02-1.15% of at least two rare-earth elements, at most 1% of microelements and the balance of Zn. The resistivity of the zinc-aluminum alloy wire is 2.0-6.0 mu omega.cm, the specific gravity of the zinc-aluminum alloy wire is 3.18-5.69 is g / cm<3>, and the elongation percentage of the zinc-aluminum alloy wire is 10-25%; and thus, the zinc-aluminum alloy wire can be widely used in ships, power supply towers, large-size storage tanks, underground pipelines, tunnel frames and other facilities, and has very wide application prospects.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

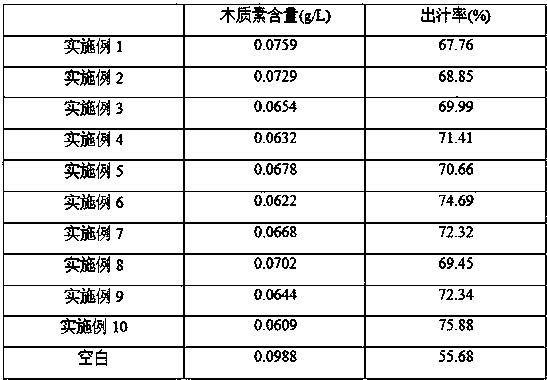

Method for suppressing lignification of fruits and vegetables by multilayer coating preservation

ActiveCN109221390ASuppress spawn rateIncrease the juice yieldFruits/vegetable preservation by coatingCold airEpsilon-Polylysine

The invention relates to a method for suppressing lignification of fruits and vegetables by multilayer coating preservation, and belongs to the technical field of fruit preservation. The method comprises the following steps: uniformly mixing hemicellulose, glucomannan, soy protein isolate and xanthan gum to form a film-forming substrate, then mixing the film-forming substrate with water, adding glycerin and / or potassium sorbate, and cooling the mixture to room temperature for later use to prepare film liquid A; immersing the fruits and vegetables in the prepared film liquid A for 30 s to 2 min, drying by cold air or at room temperature; adding salicylic acid, spermidine and spermine into the film liquid A, uniformly mixing to obtain film liquid B, immersing the treated fruits and vegetables in the film liquid B for 30 s to 2 min, drying by cold air or at room temperature; adding a bacteriostatic agent natamycin or epsilon-polylysine into a chitosan solution to obtain film liquid C, immersing the treated fruits and vegetables in the film liquid C for 30 s to 2 min, and drying by cold air or at room temperature. The method adopts multilayer coating preservation treatment to effectively suppress the formation speed of fruit and vegetable lignin.

Owner:KUNMING UNIV OF SCI & TECH

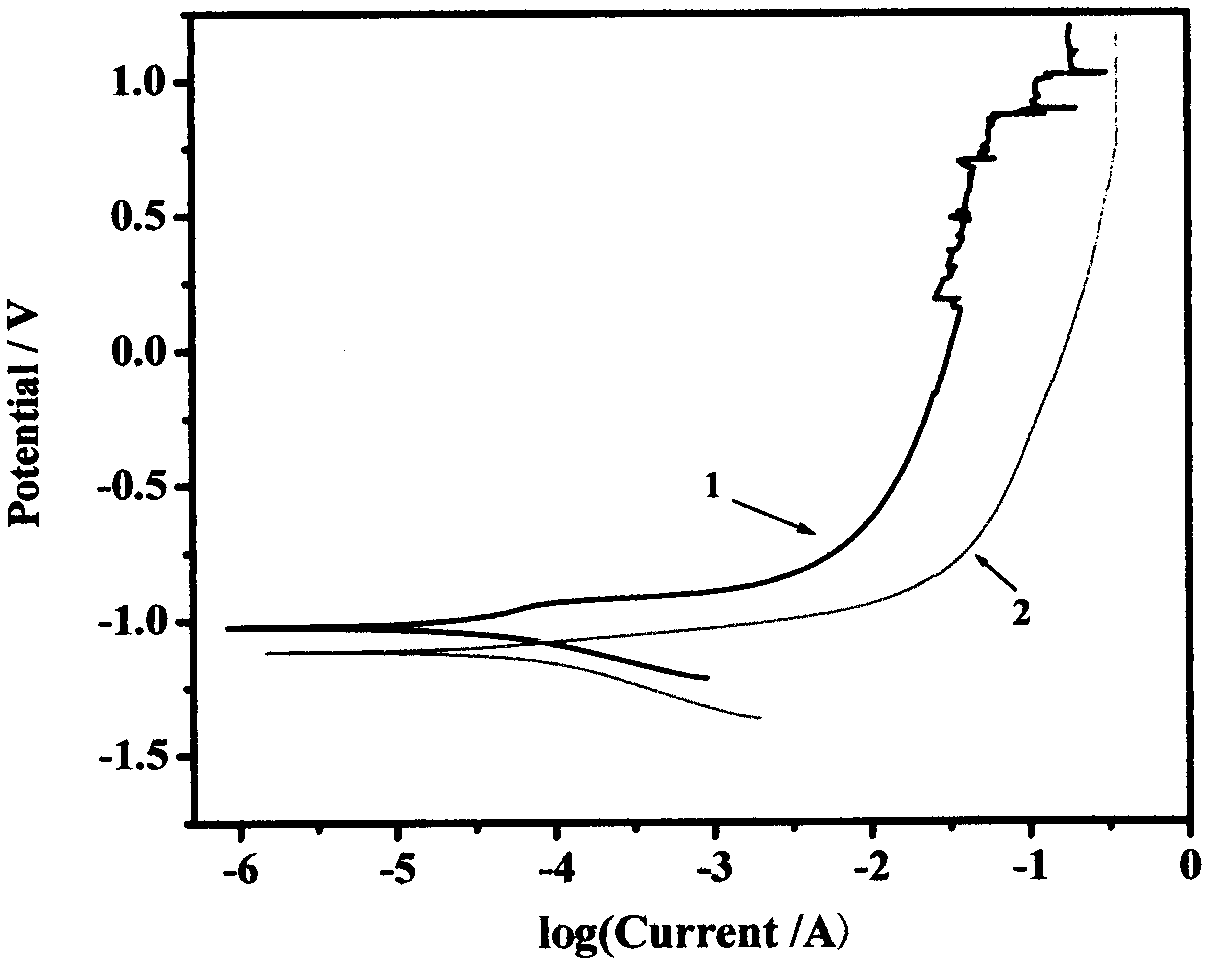

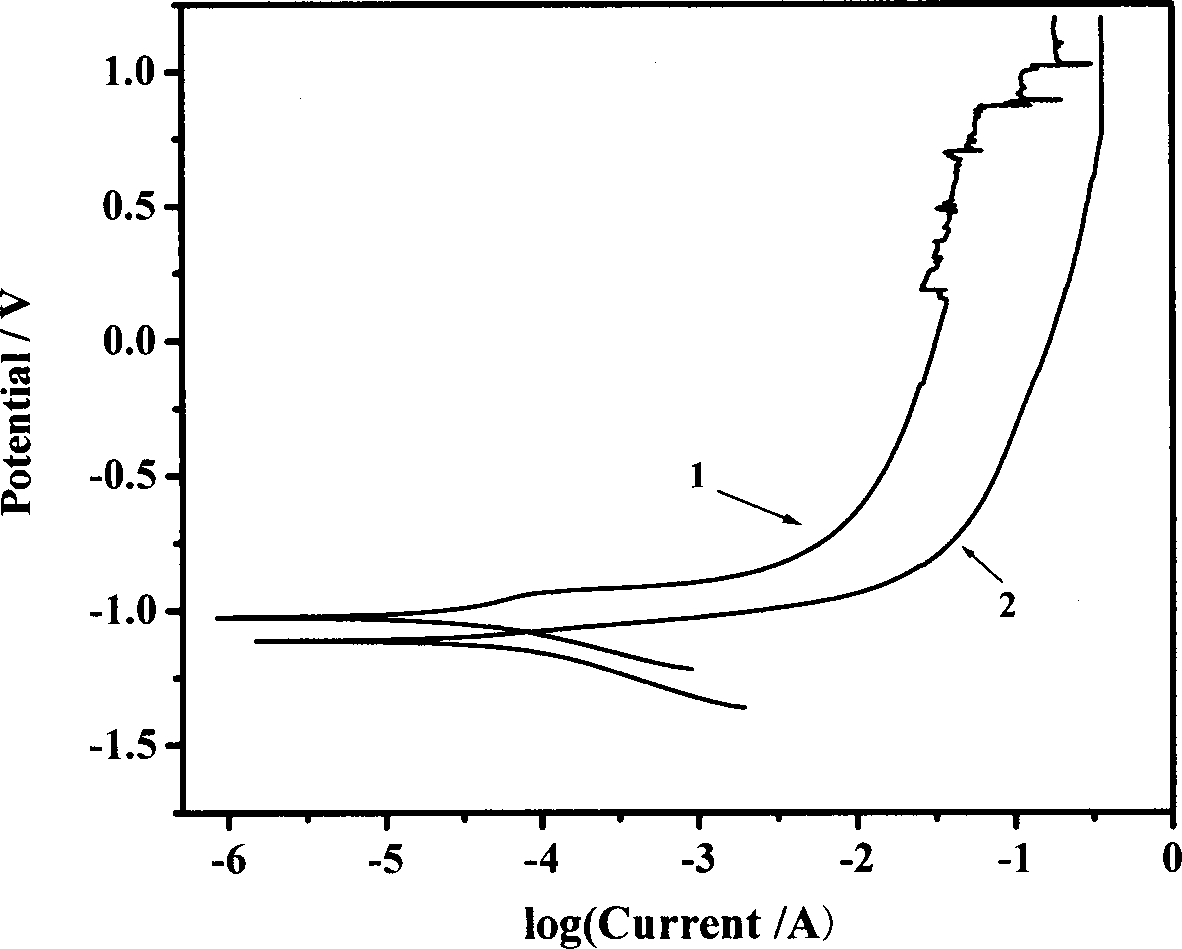

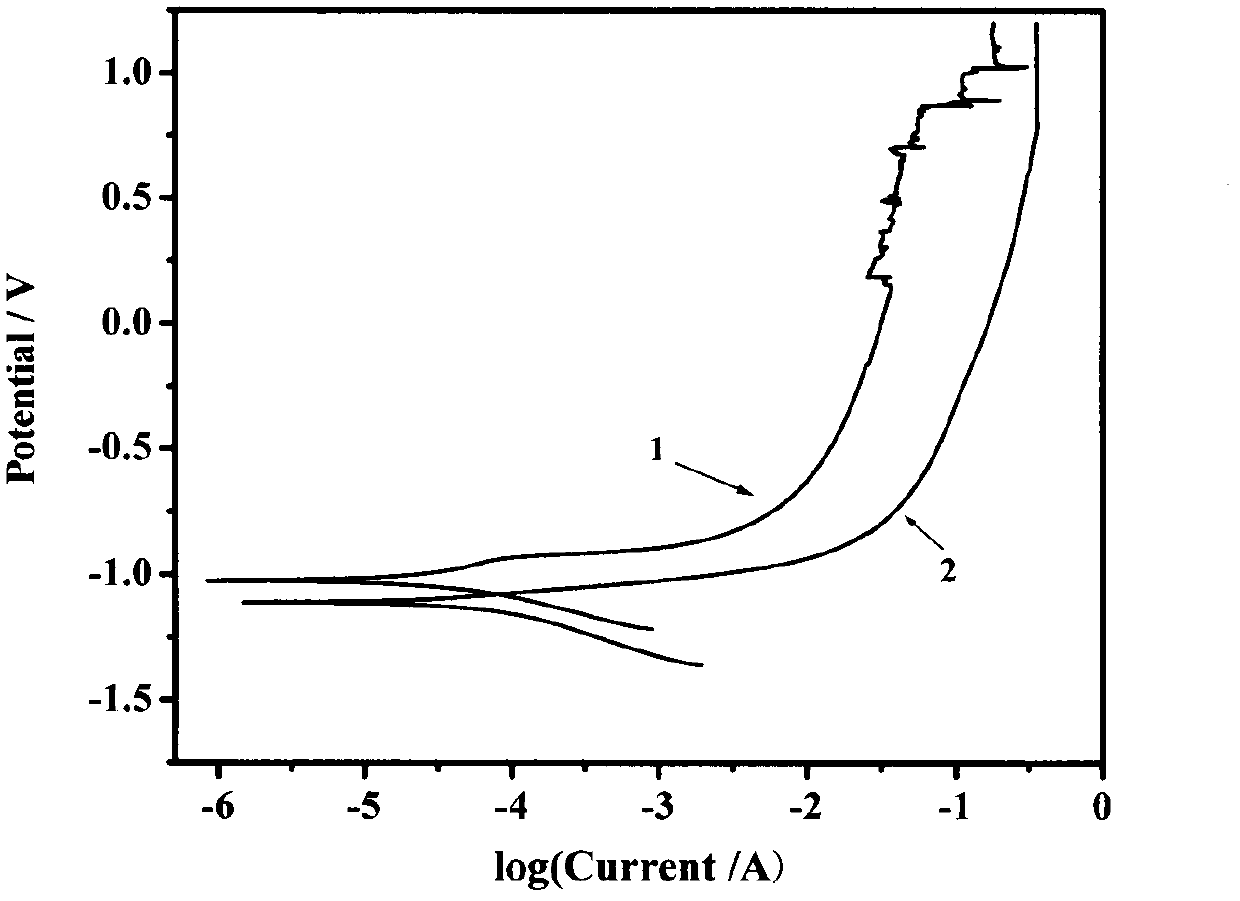

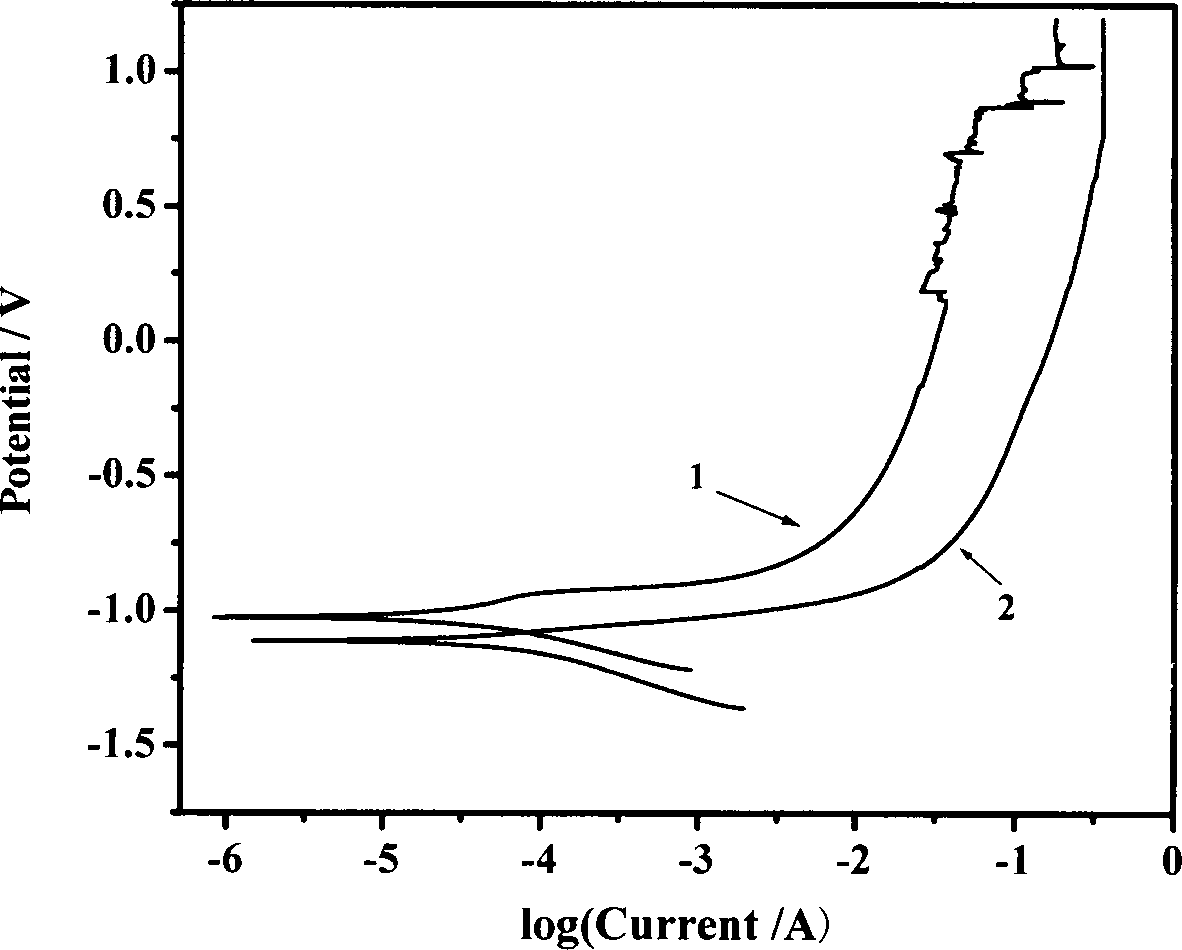

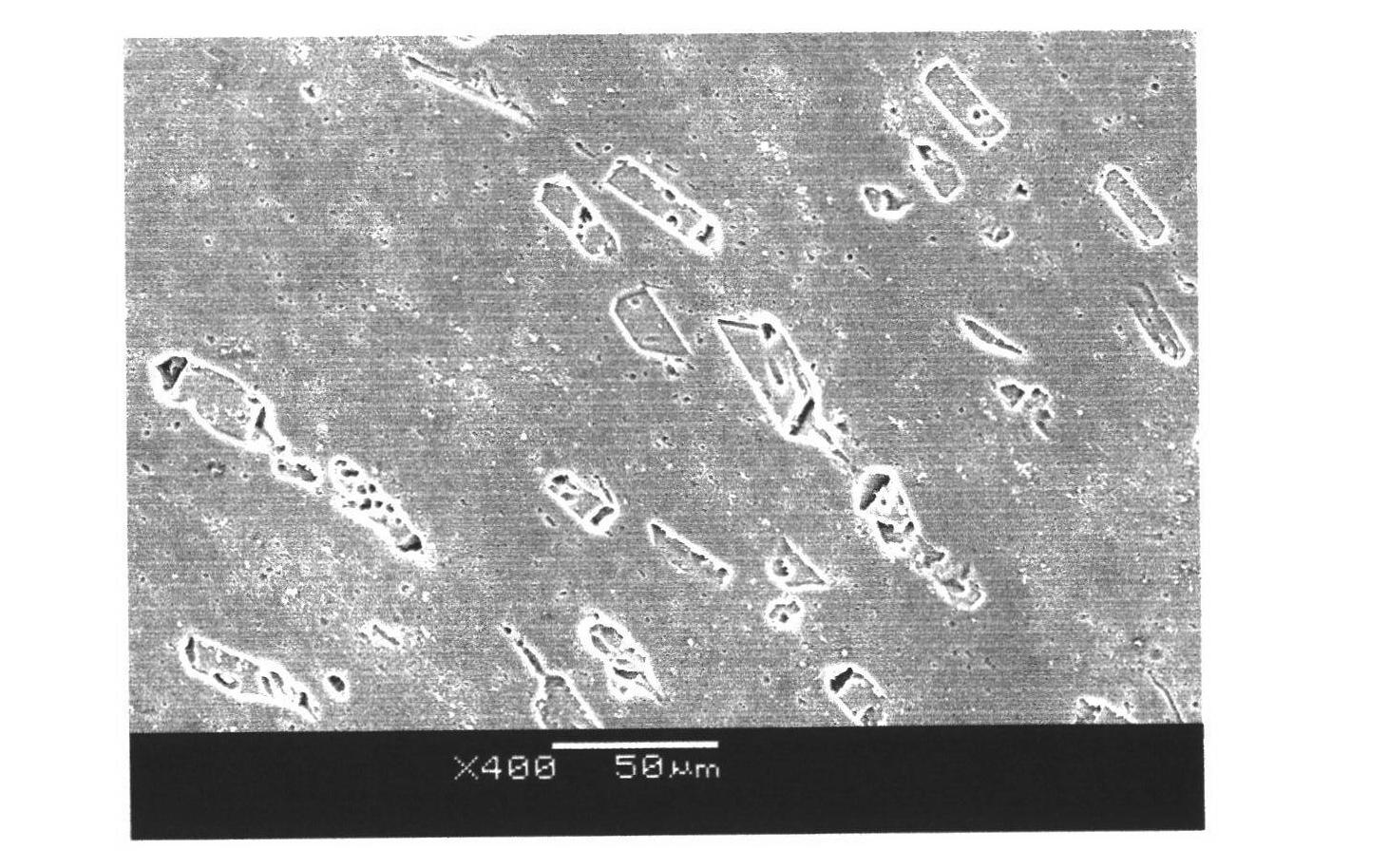

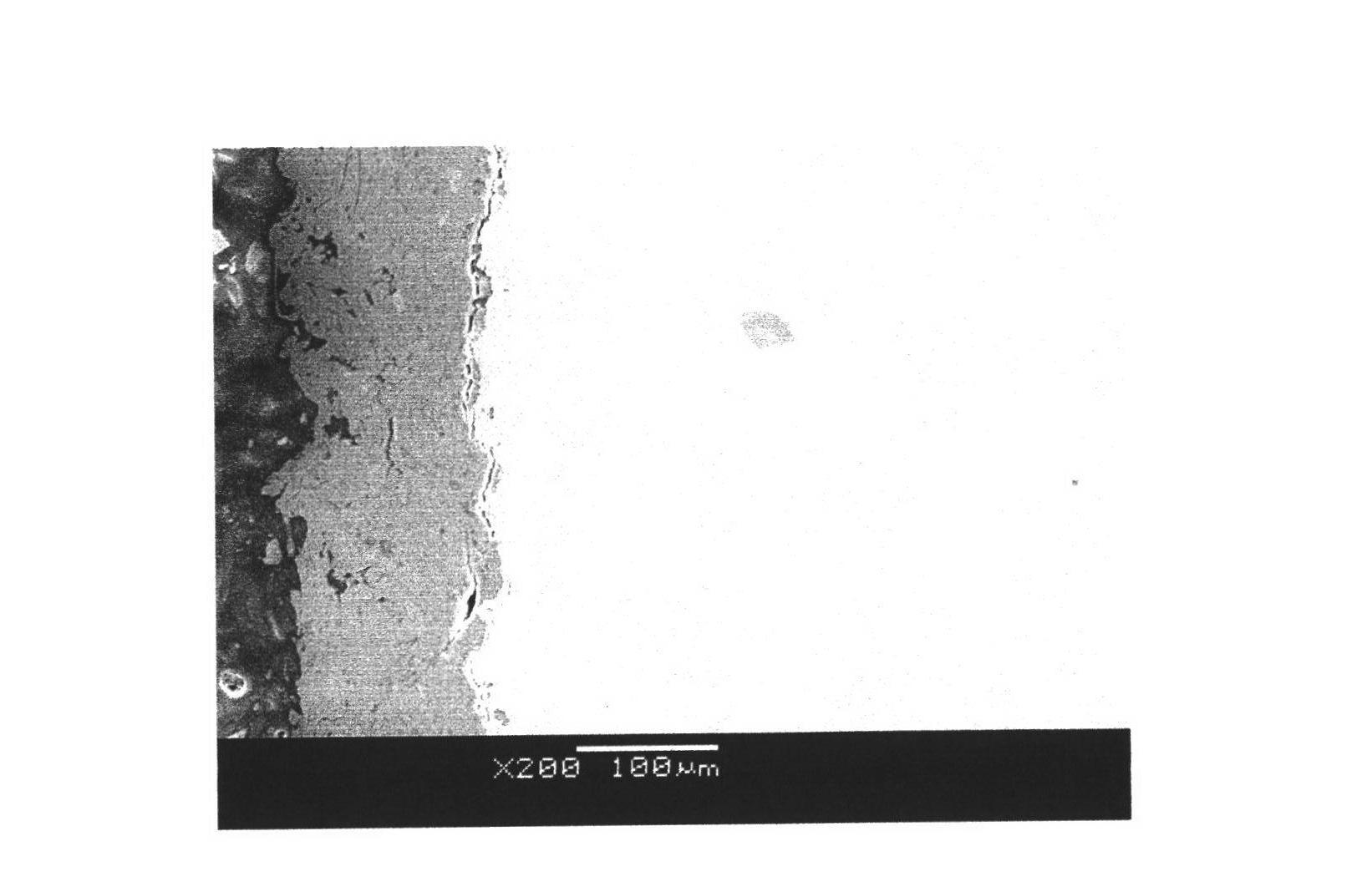

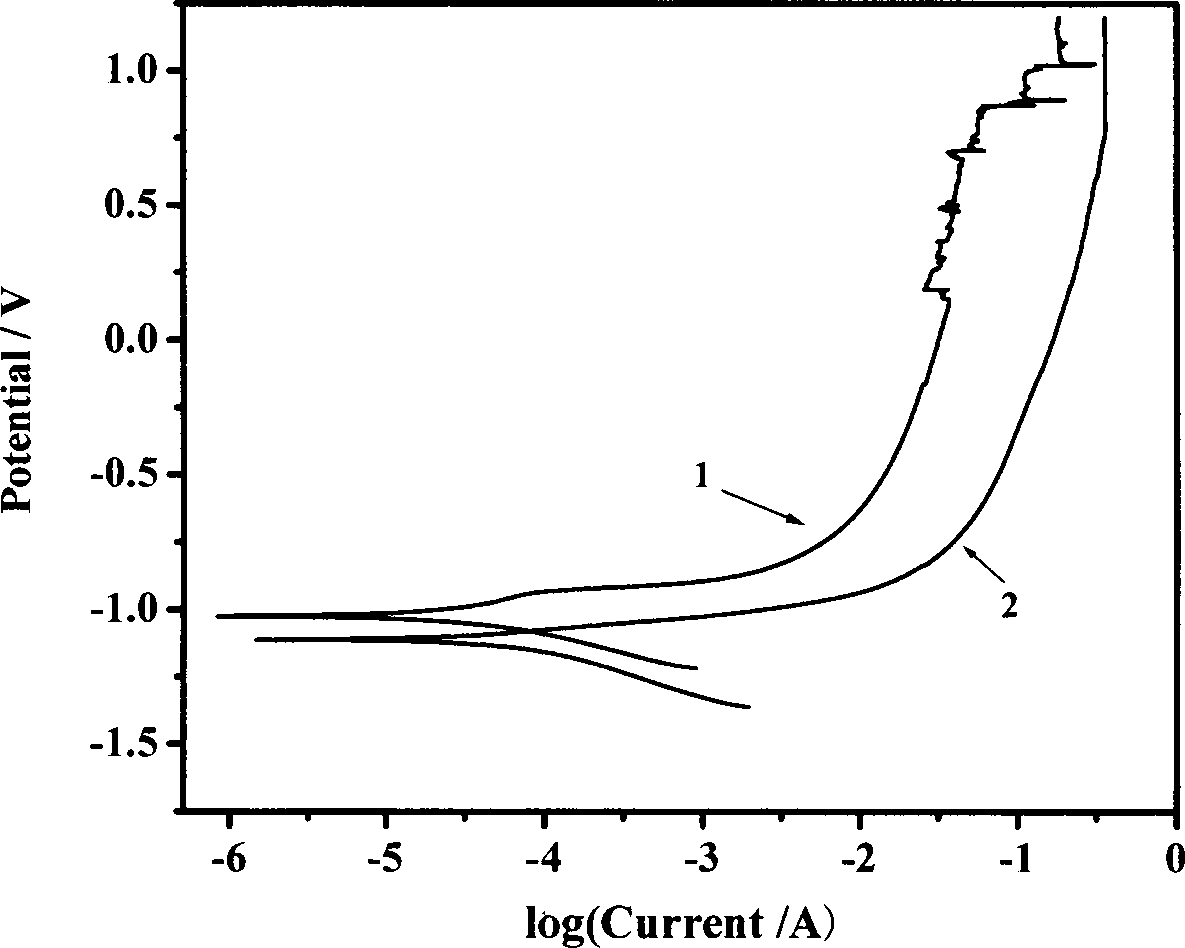

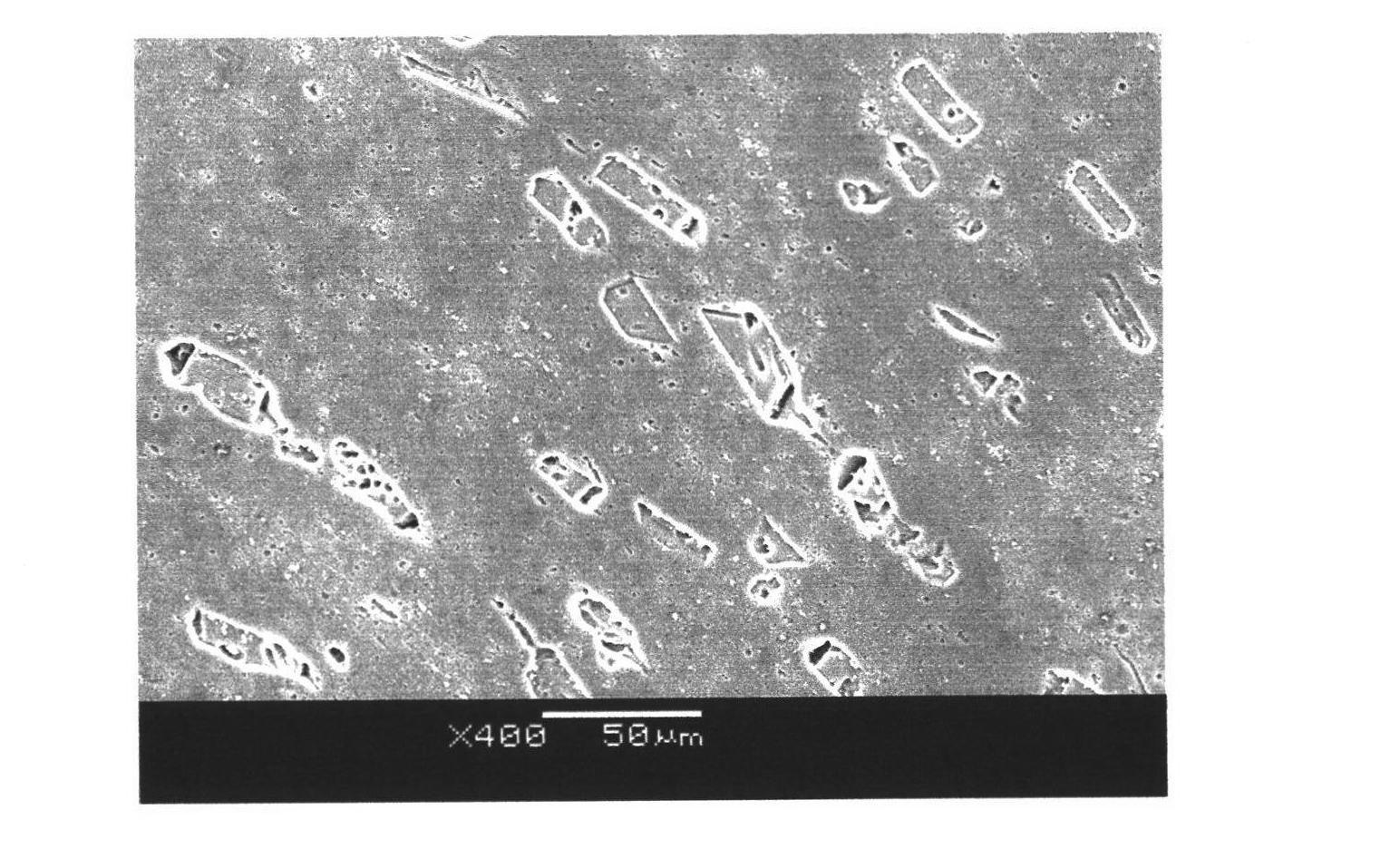

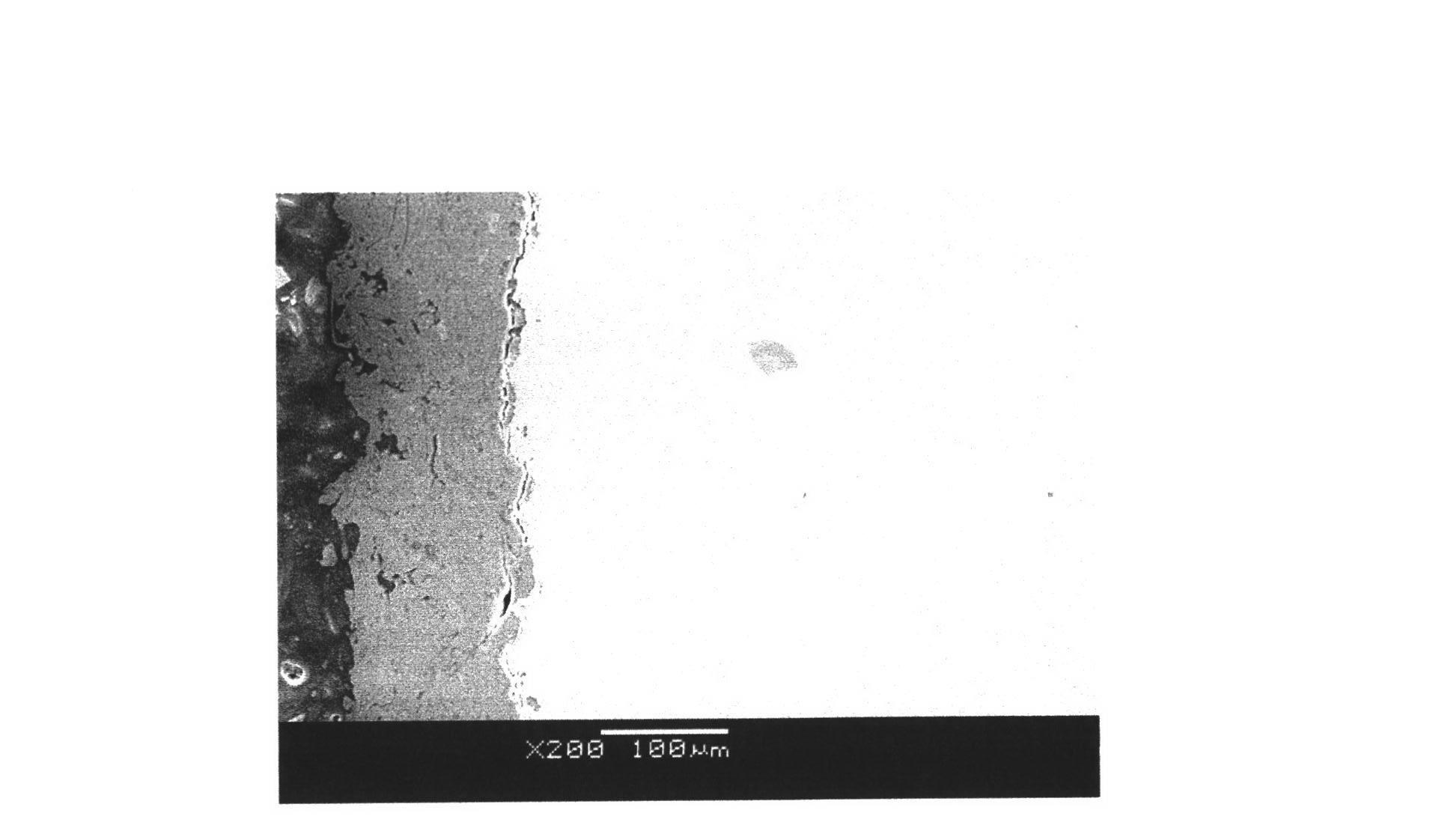

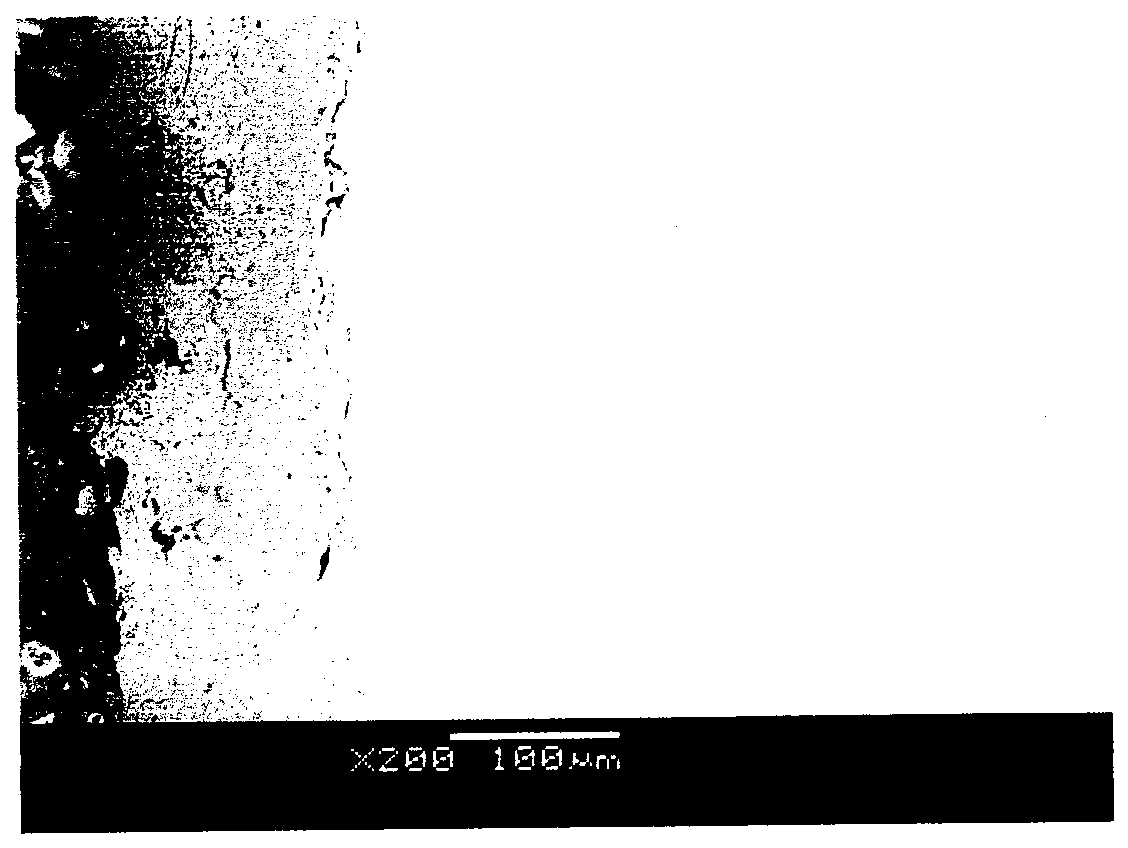

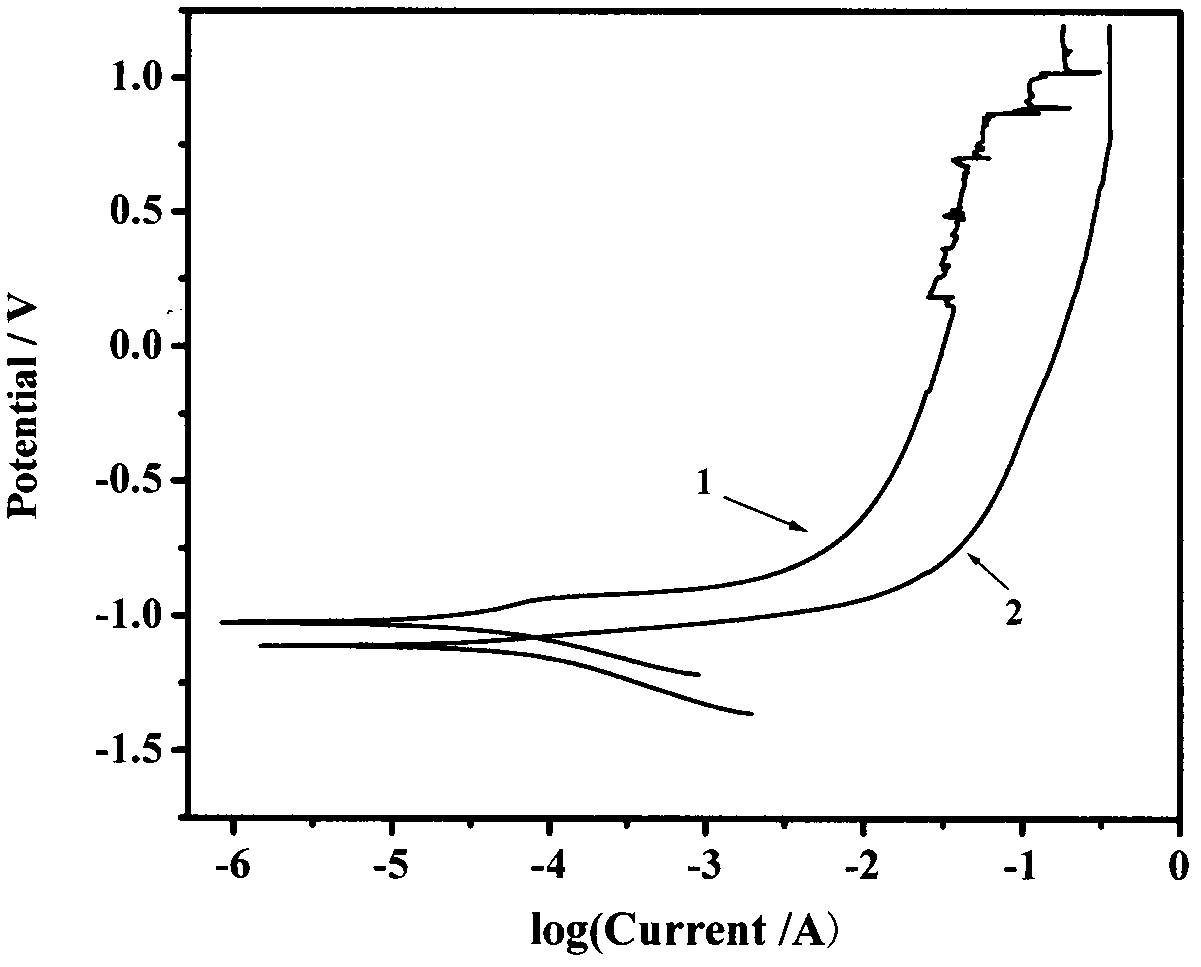

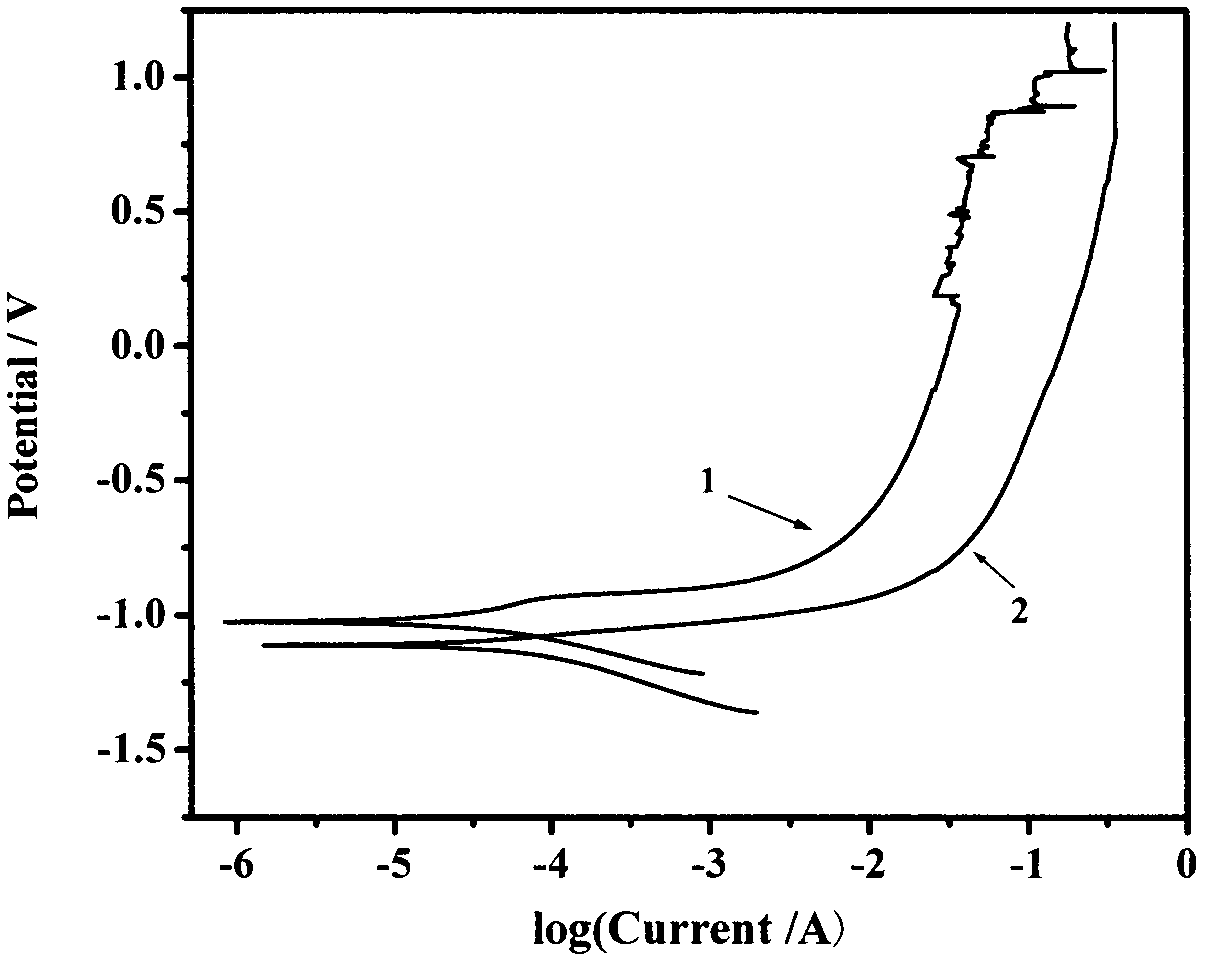

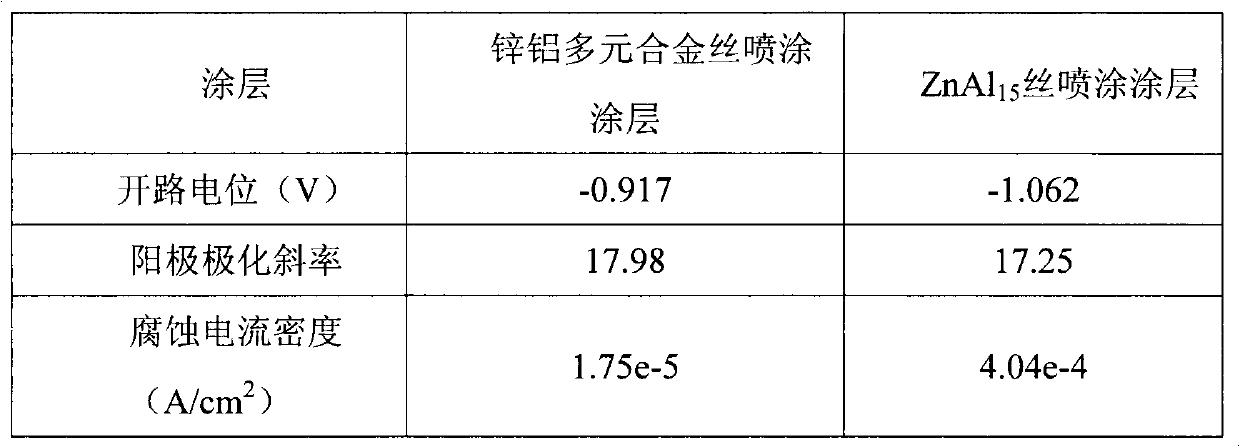

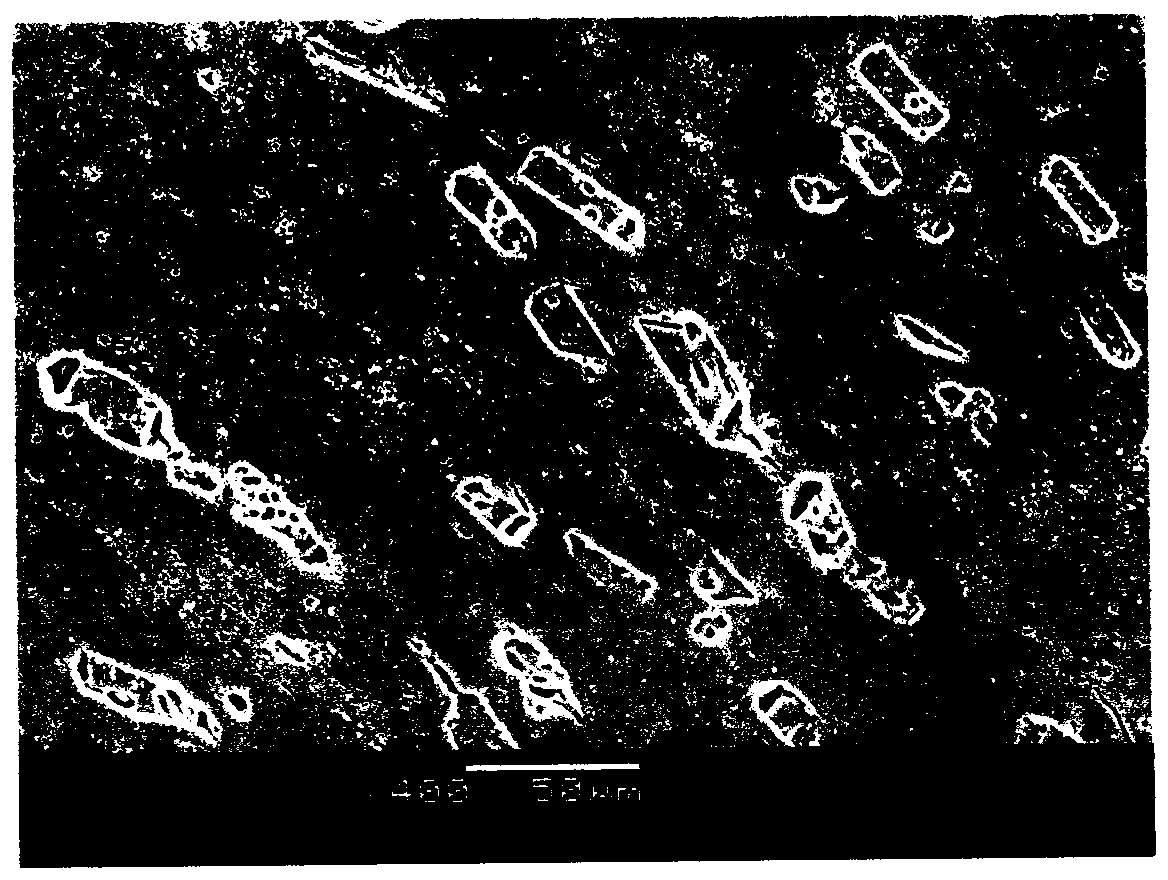

Pr-Nd-containing zinc-aluminum alloy wire and manufacturing method thereof

ActiveCN102703777AReduce harmful effectsHigh strengthMolten spray coatingRare-earth elementLarge size

The invention relates to a multielement zinc-aluminum alloy wire which comprises the following components in percentage by weight: 15-69% of Al, 0.2-3% of Si, 0.1-5% of Mg, 0.01-0.2% of Pr, 0.01-0.2% of Nd (the total amount of the two rare-earth elements is 0.02-0.40%), at most 1% of microelements and the balance of Zn. The resistivity of the zinc-aluminum alloy wire is 2.0-6.0 mu omega.cm, the specific gravity of the zinc-aluminum alloy wire is 3.18-5.69 is g / cm<3>, and the elongation percentage of the zinc-aluminum alloy wire is 10-25%; and thus, the zinc-aluminum alloy wire can be widely used in ships, power supply towers, large-size storage tanks, underground pipelines, tunnel frames and other facilities, and has very wide application prospects.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

La-Nd-containing zinc-aluminum alloy wire and production method thereof

The invention relates to a multi-element zinc-aluminum alloy wire. The multi-element zinc-aluminum alloy wire comprises, by weight percent, 15%-69% of Al, 0.2-3% of Si, 0.1-5% of Mg, 0.01-0.7% of La, 0.01-0.2% of Nd, not more than 1% of added microelements, and the balance of Zn, wherein the two rare earth elements have a total amount of 0.02-0.76%. The zinc-aluminum alloy wire has a resistivity of 2.0-6.0 Mu Omega / cm, a specific gravity of 3.18-5.69g / cm<3>, and an elongation of 10-25%. The multi-element zinc-aluminum alloy wire is widely applicable to ships, power supply towers, large storage tanks, underground pipelines and facilities such as tunnel frames, and has broad application prospect.

Owner:JIANGSU LINLONG NEW MATERIALS

Aluminum-titanium (Al-Ti) alloy wire containing praseodymium (Pr) and neodymium (Nd) and method for manufacturing same

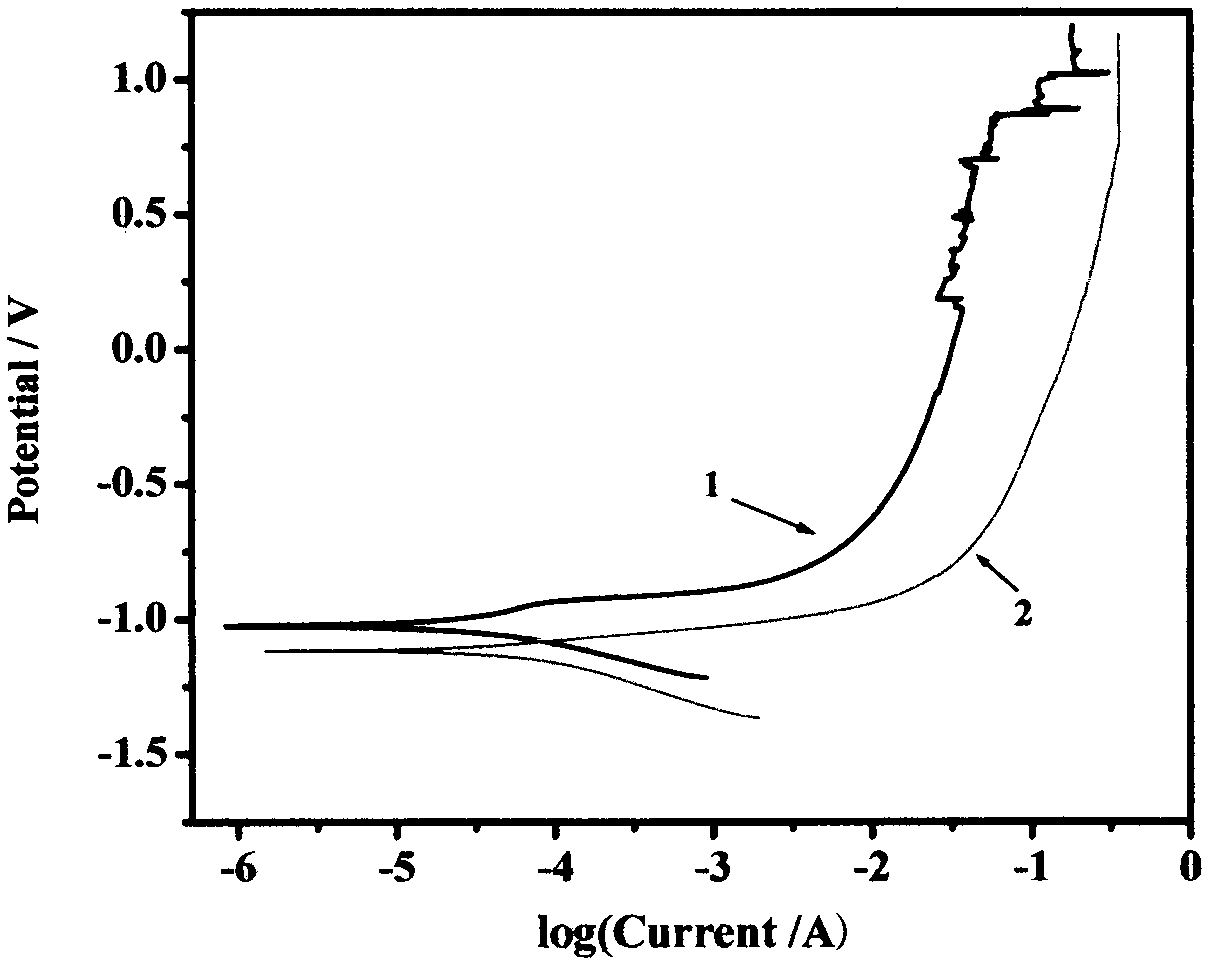

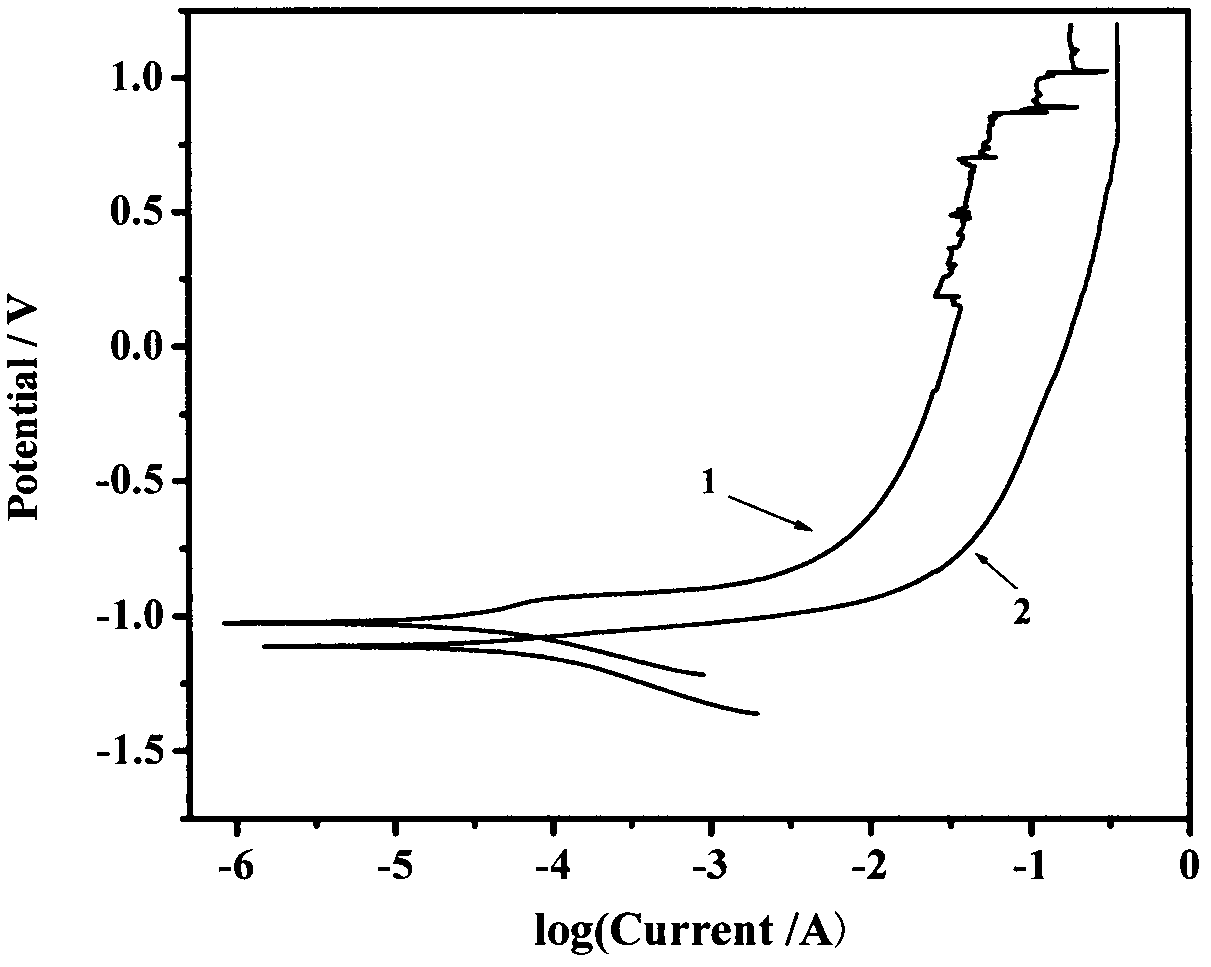

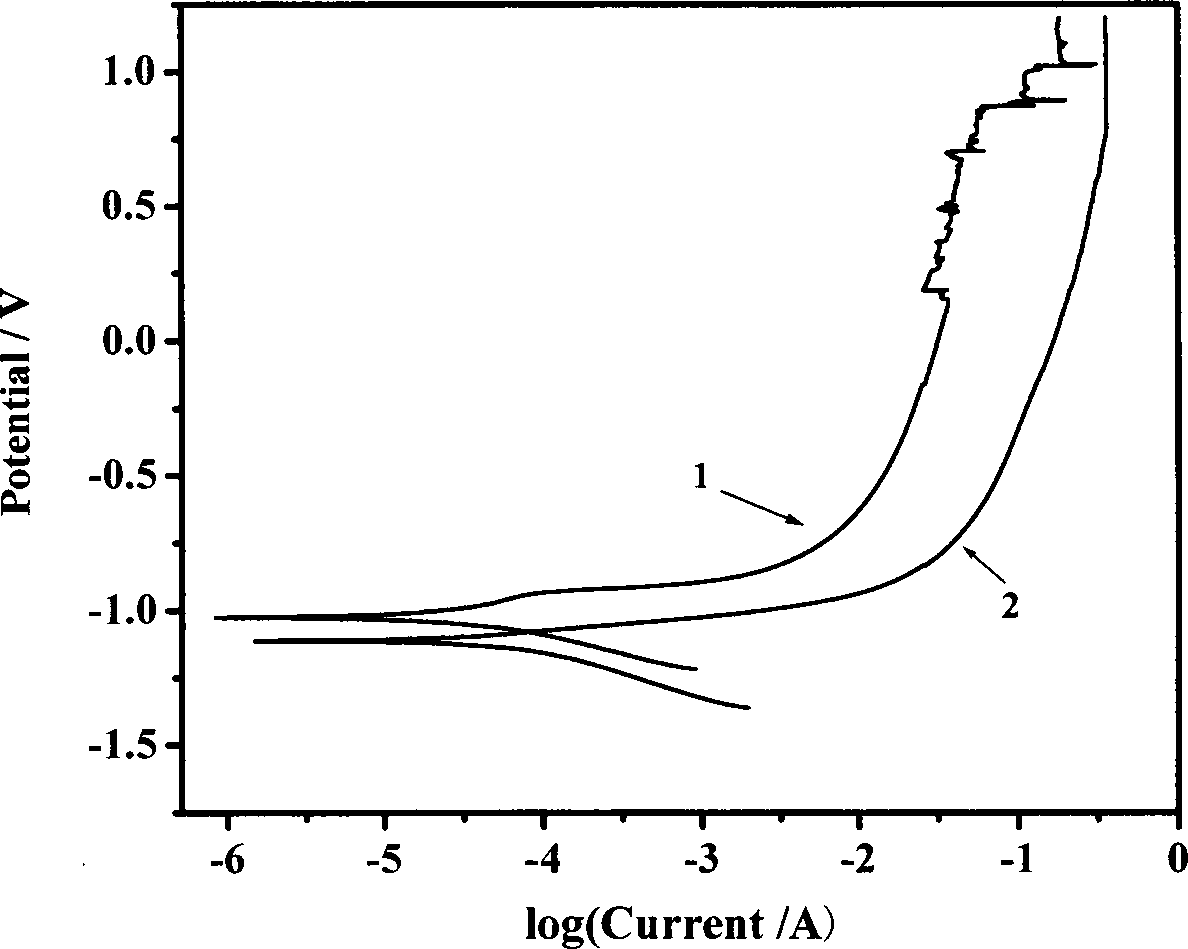

ActiveCN102605215AImprove passivation effectStrong expandabilityMolten spray coatingRare earthTitanium

The invention relates to a multi-component aluminum-titanium (Al-Ti) alloy wire which comprises the following components in percent by weight: 94-97% of Al, 0.05-1% of vanadium (V), 2-5% of Ti, 0.01-0.2% of praseodymium (Pr), 0.01-0.2% of neodymium (Nd). The total percent by weight of the two rear-earth elements which are Pr and Nd is 0.02-0.40%, and the total percent by weight of the added traceelements is 1% or less. The Al-Ti alloy wire has the resistivity of 2.0-6.0 muohm.cm, the specific weight of 2.60-2.75g / cm<3> and the elongation rate of 10-25%.

Owner:JIANGSU LINLONG NEW MATERIALS

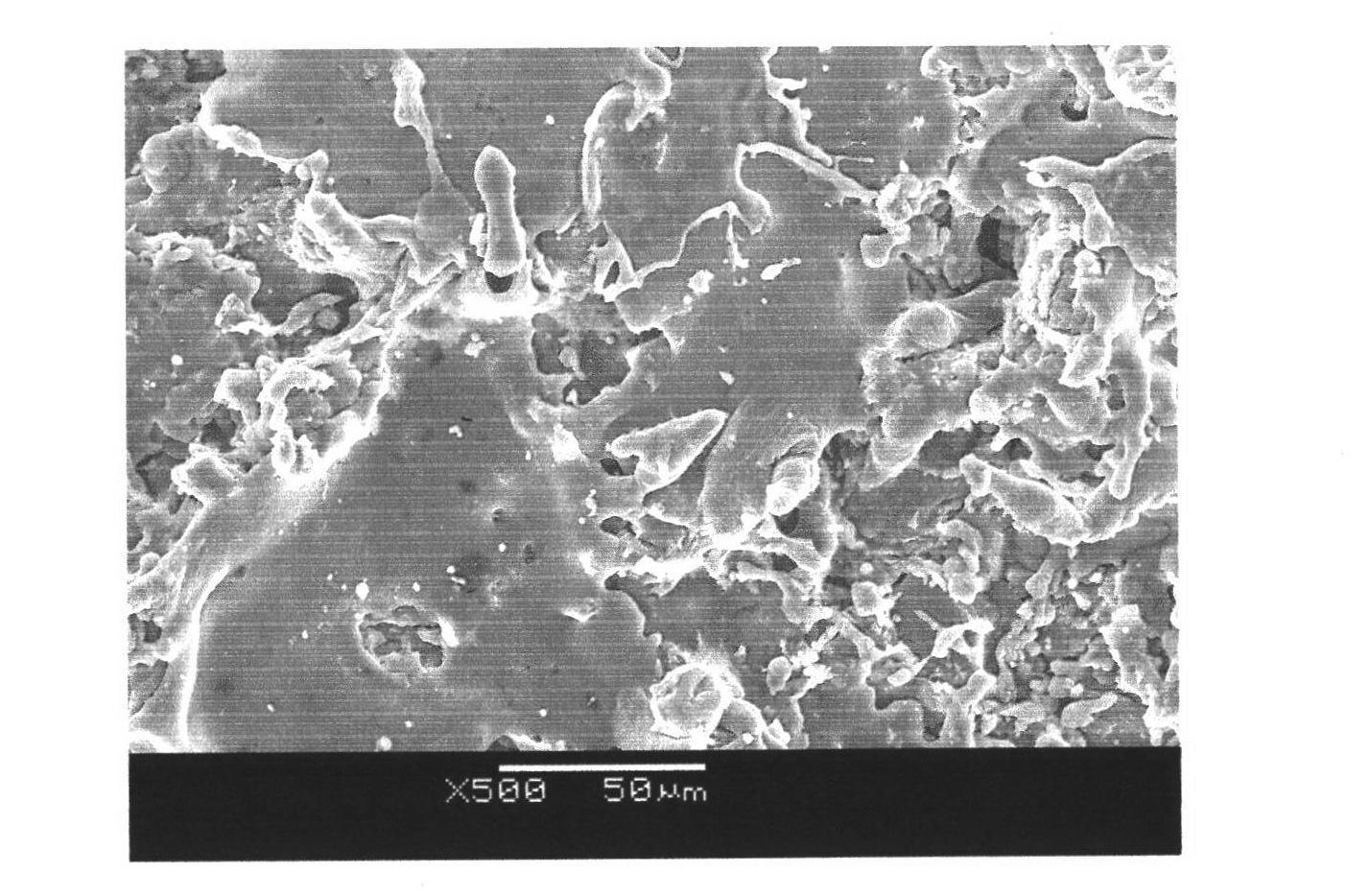

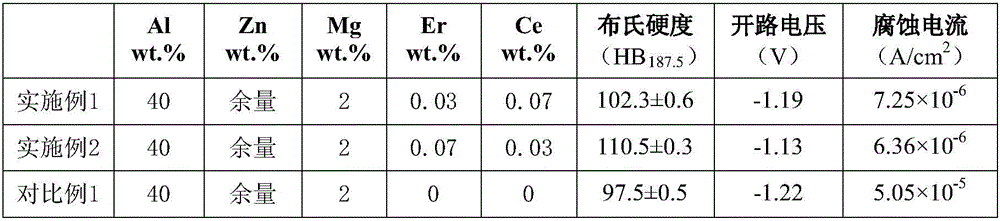

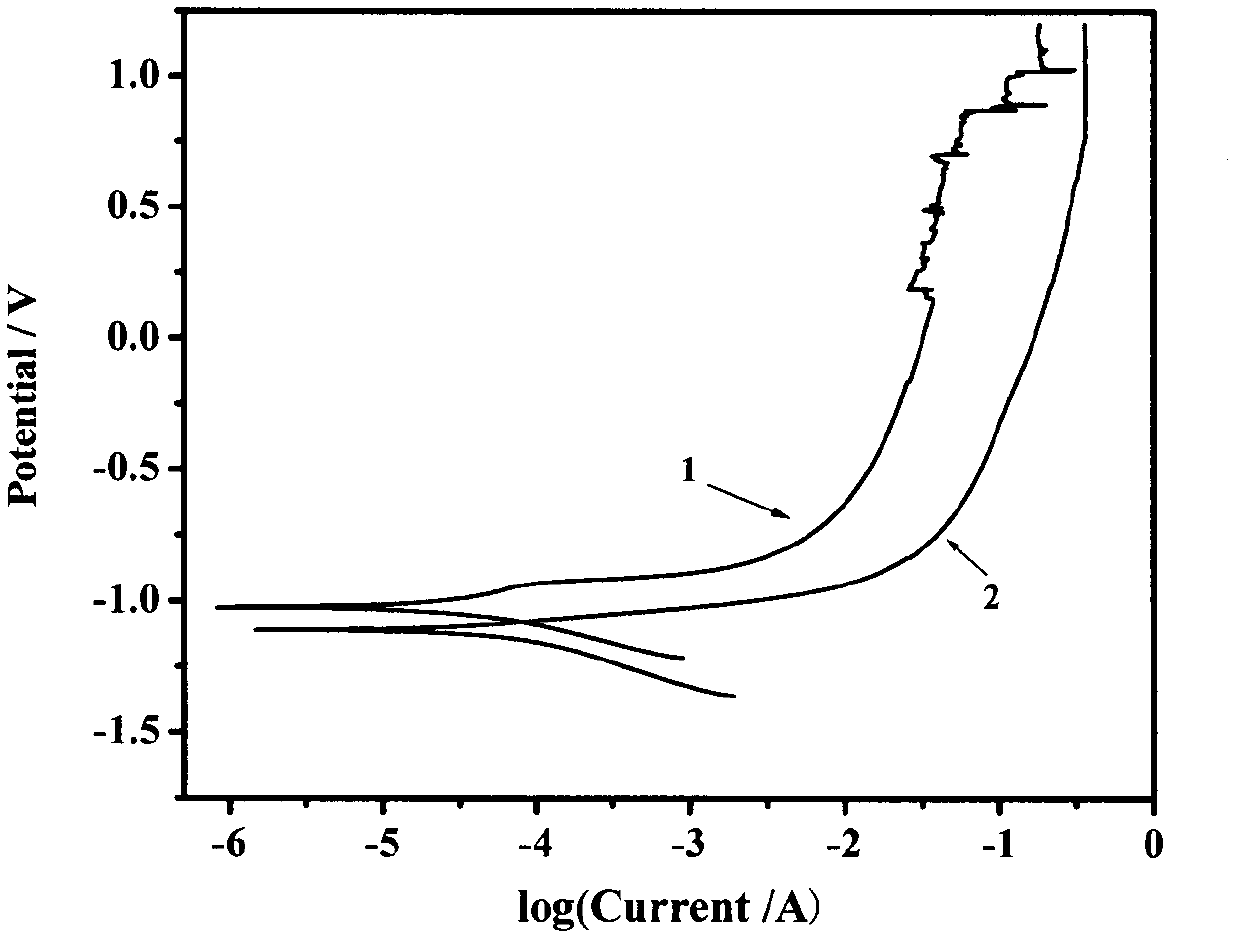

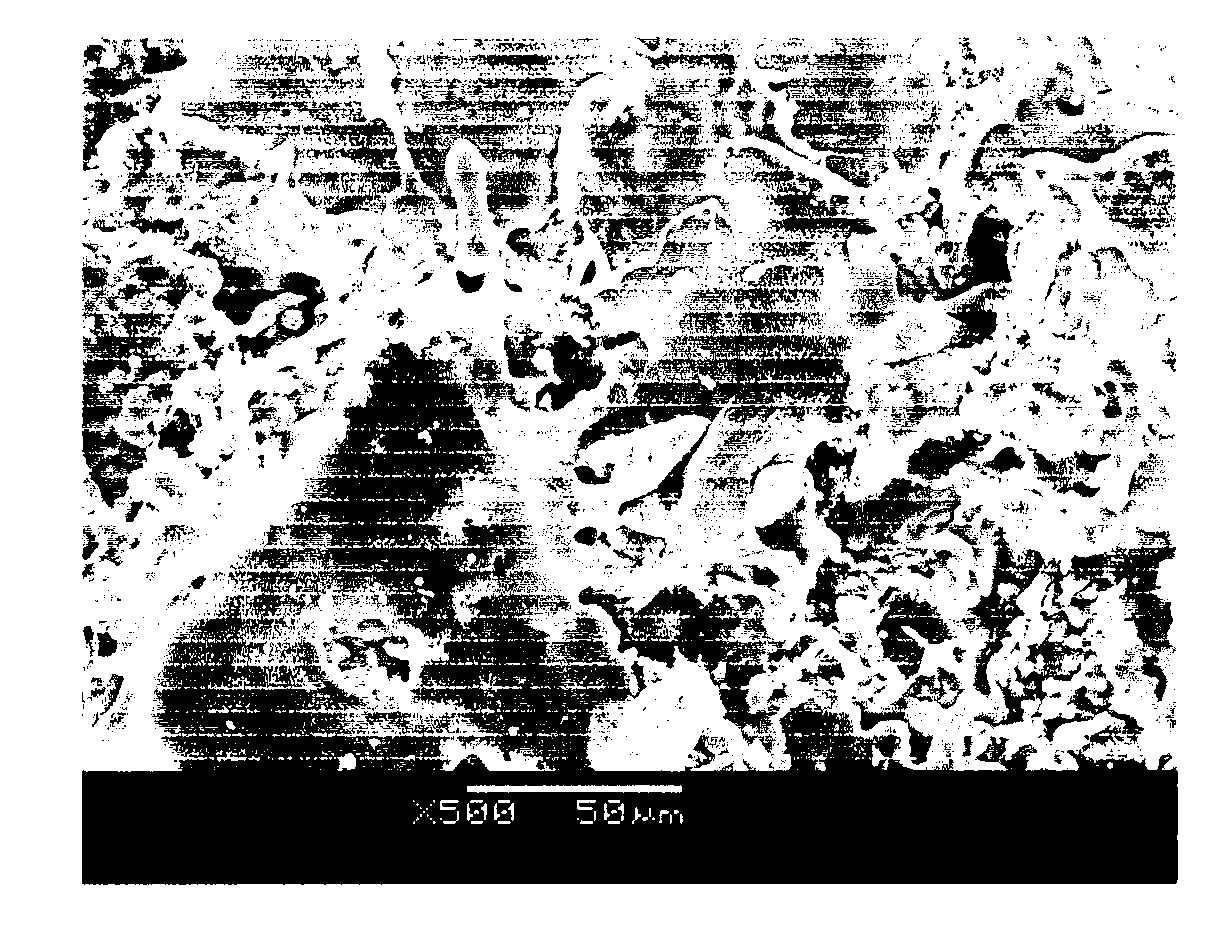

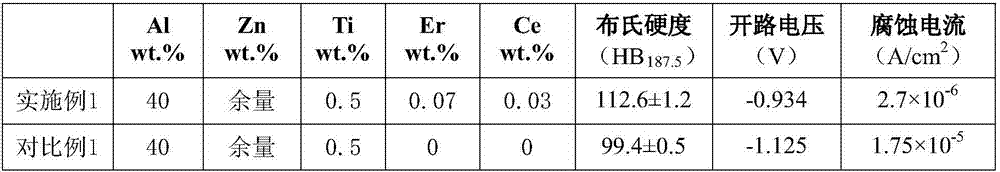

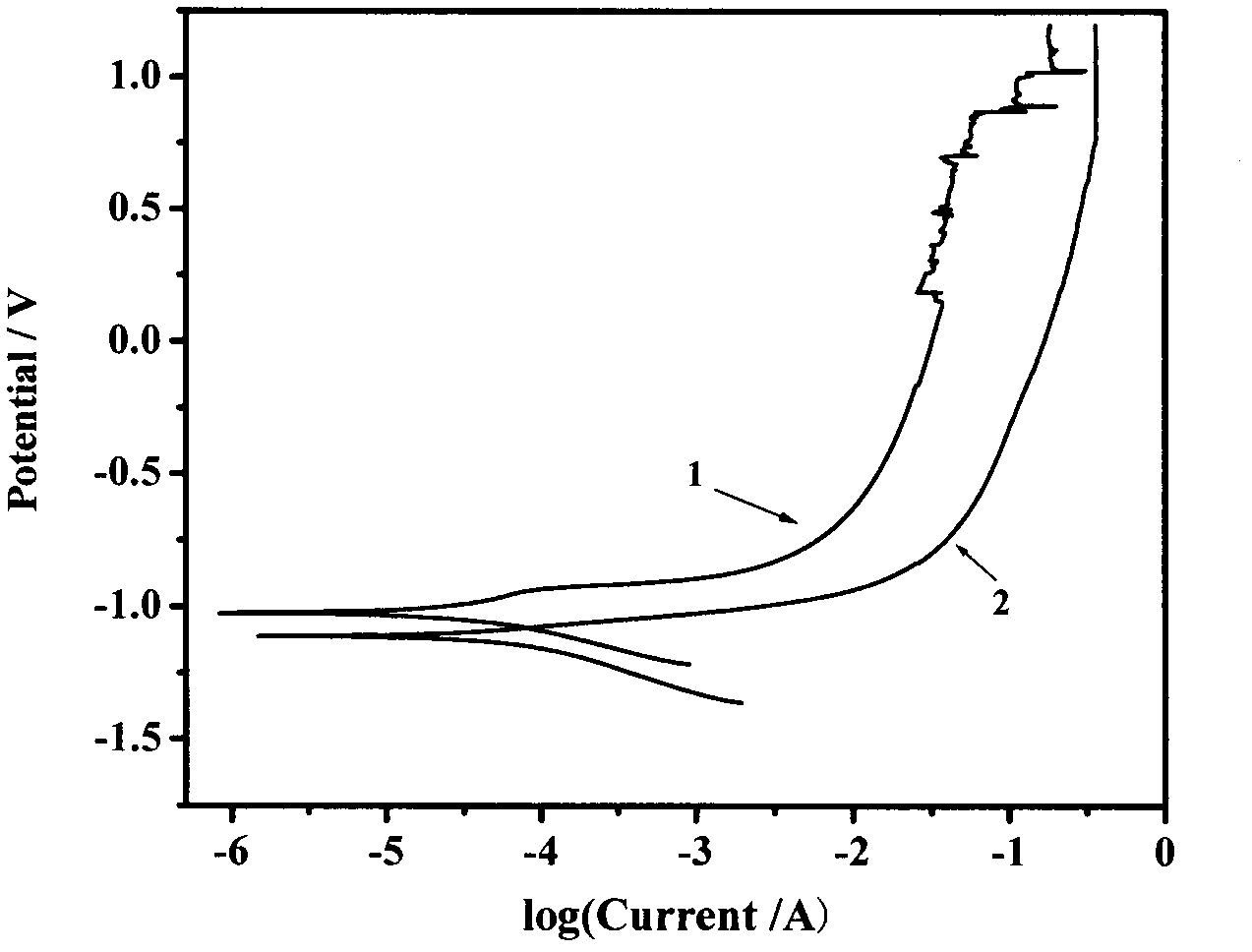

Zinc-aluminum-magnesium alloy wire containing rare earth, and preparation method and application thereof

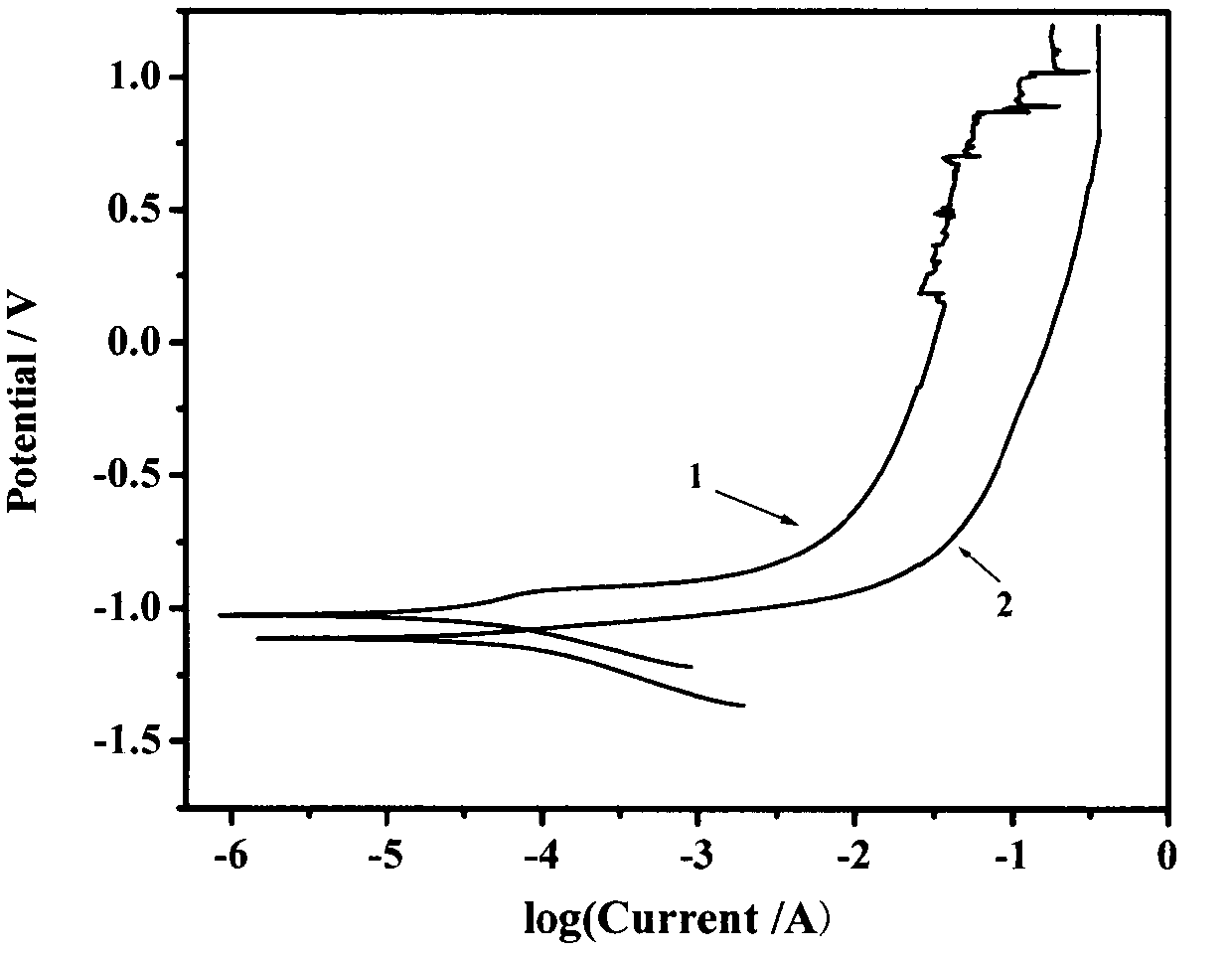

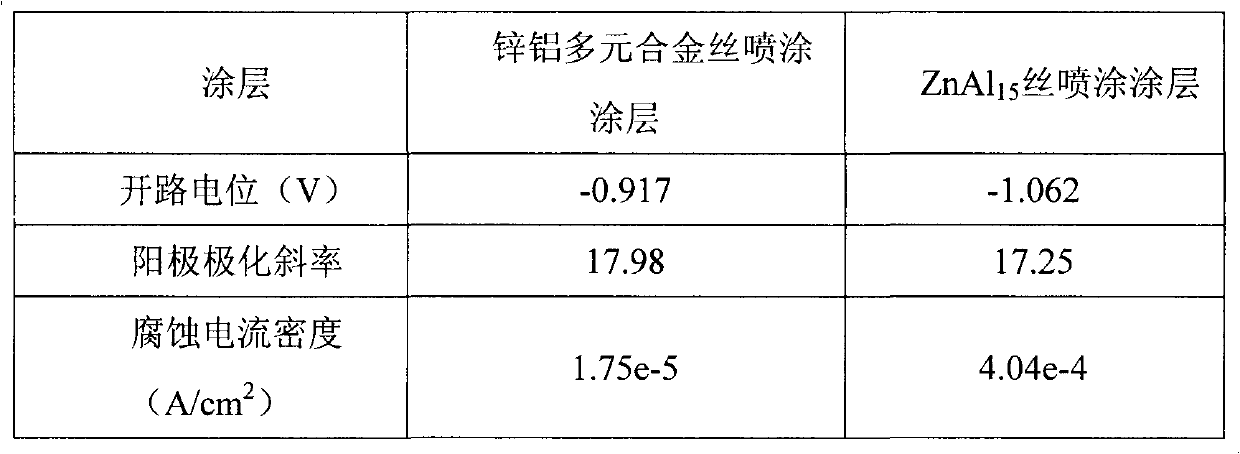

The invention discloses a zinc-aluminum-magnesium alloy wire containing rare earth, and a preparation method and application thereof. The zinc-aluminum-magnesium alloy wire is prepared from the following components: 15 to 40 percent of aluminum, 0.2 to 4.0 percent of magnesium, 0.02 to 0.2 percent of rare earth elements, i.e. cerium and erbium, not larger than 0.025 percent of impurities, and the balance of zinc, wherein the mass ratio of the two rare earth elements i.e. Ce to Er is 3:7 or 7:3. According to the zinc-aluminum-magnesium alloy wire containing the rare earth provided by the invention, the rare earth elements such as the cerium and the erbium are added, so that the corrosion resistance is improved, meanwhile, the zinc-aluminum-magnesium alloy wire has the advantages of high strength, high hardness, low price and the like, and can replace a traditional zinc wire so as to be used for the fields such as spraying anticorrosion engineering, and a zinc-aluminum-magnesium alloy heat coating has an excellent adhesive force, favorable physical and mechanical properties and a corrosion resisting property. The average annual corrosion rate of the zinc-aluminum-magnesium alloy heat coating is larger than the average annual corrosion rates of a heat spraying zinc coating, a zinc aluminum alloy coating, a zinc aluminum pseudo alloy coating and the like, and an anodic protection effect of the zinc-aluminum-magnesium alloy heat coating is remarkably improved compared with the anodic protection effects of aluminum and other aluminum alloy heat spraying metal layers; the whole wire material processing and manufacturing process is simple and convenient, and the cost is lower.

Owner:GUANGZHOU YUEHUI METAL MACHINERY PROTECTION TECH +2

Zinc-aluminum alloy wire containing La, Ce and Nd and production method thereof

ActiveCN102703780AReduce harmful effectsHigh strengthMolten spray coatingRare-earth elementPower tower

The invention relates to a multi-element zinc-aluminum alloy wire. The multi-element zinc-aluminum alloy wire comprises, by weight percent, 15%-69% of Al, 0.2-3% of Si, 0.1-5% of Mg, 0.01-0.8% of Ce, 0.01-0.2% of Pr, 0.01-0.2% of Nd, not more than 1% of added microelements, and the balance of Zn, wherein the three rare earth elements have a total amount of 0.03-0.92%. The zinc-aluminum alloy wirehas a resistivity of 2.0-6.0 Mu omega / cm, a specific gravity of 3.18-5.69g / cm<3>, and an elongation of 10-25%. The multi-element zinc-aluminum alloy wire is widely applicable to ships, power towers, large storage tanks, underground pipelines and facilities such as tunnel frames, and has broad application prospect.

Owner:JIANGSU LINLONG NEW MATERIALS

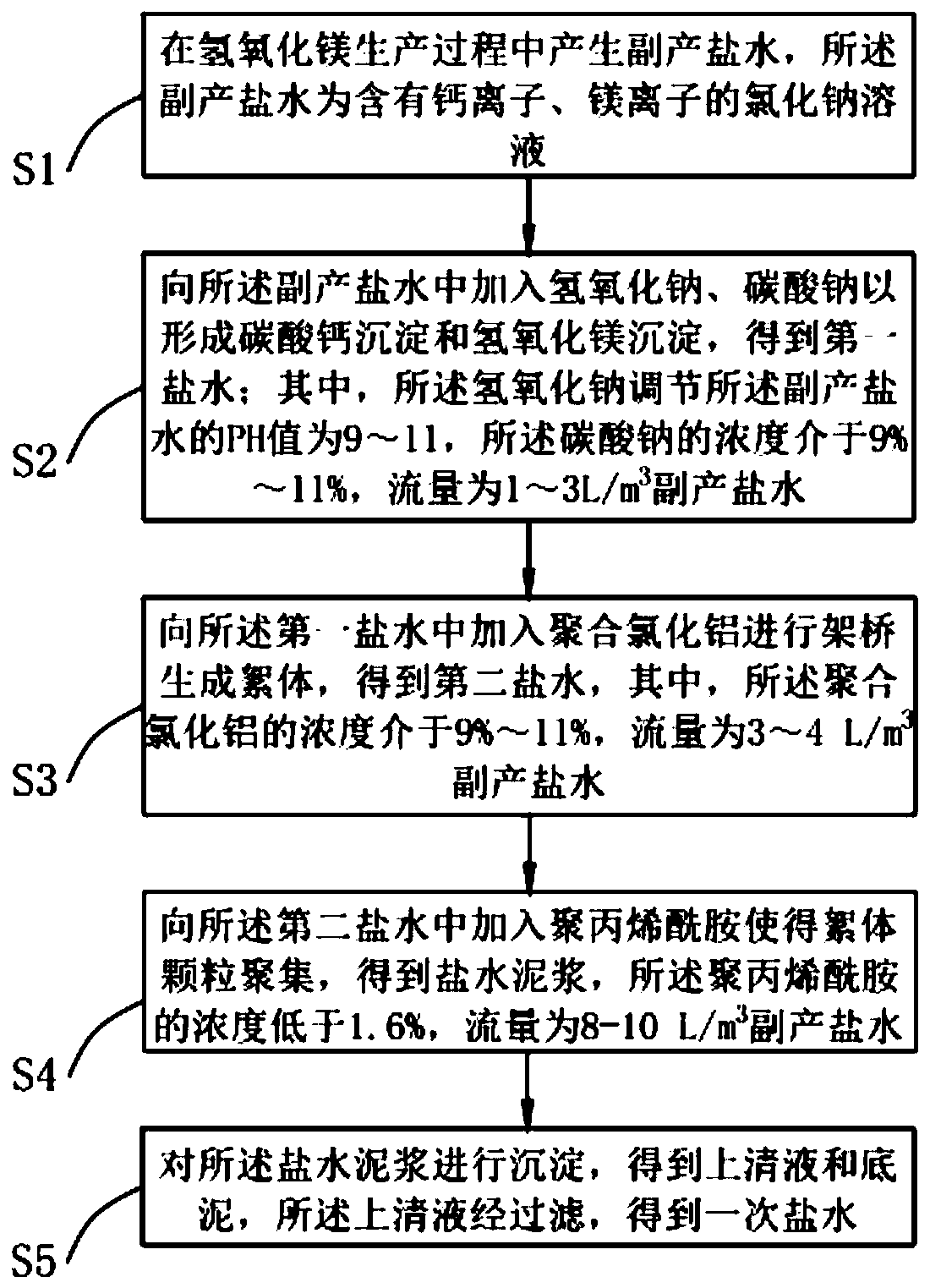

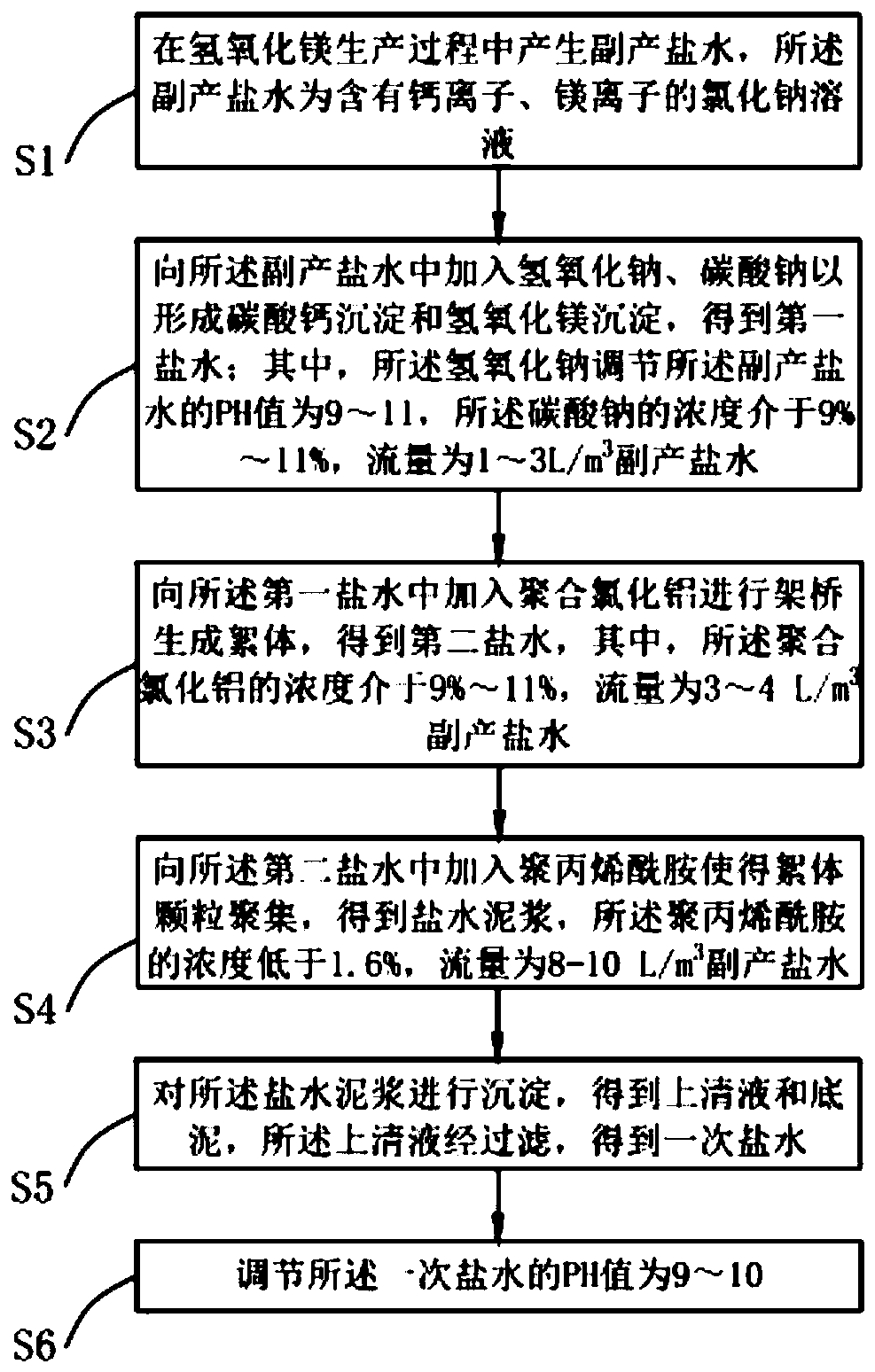

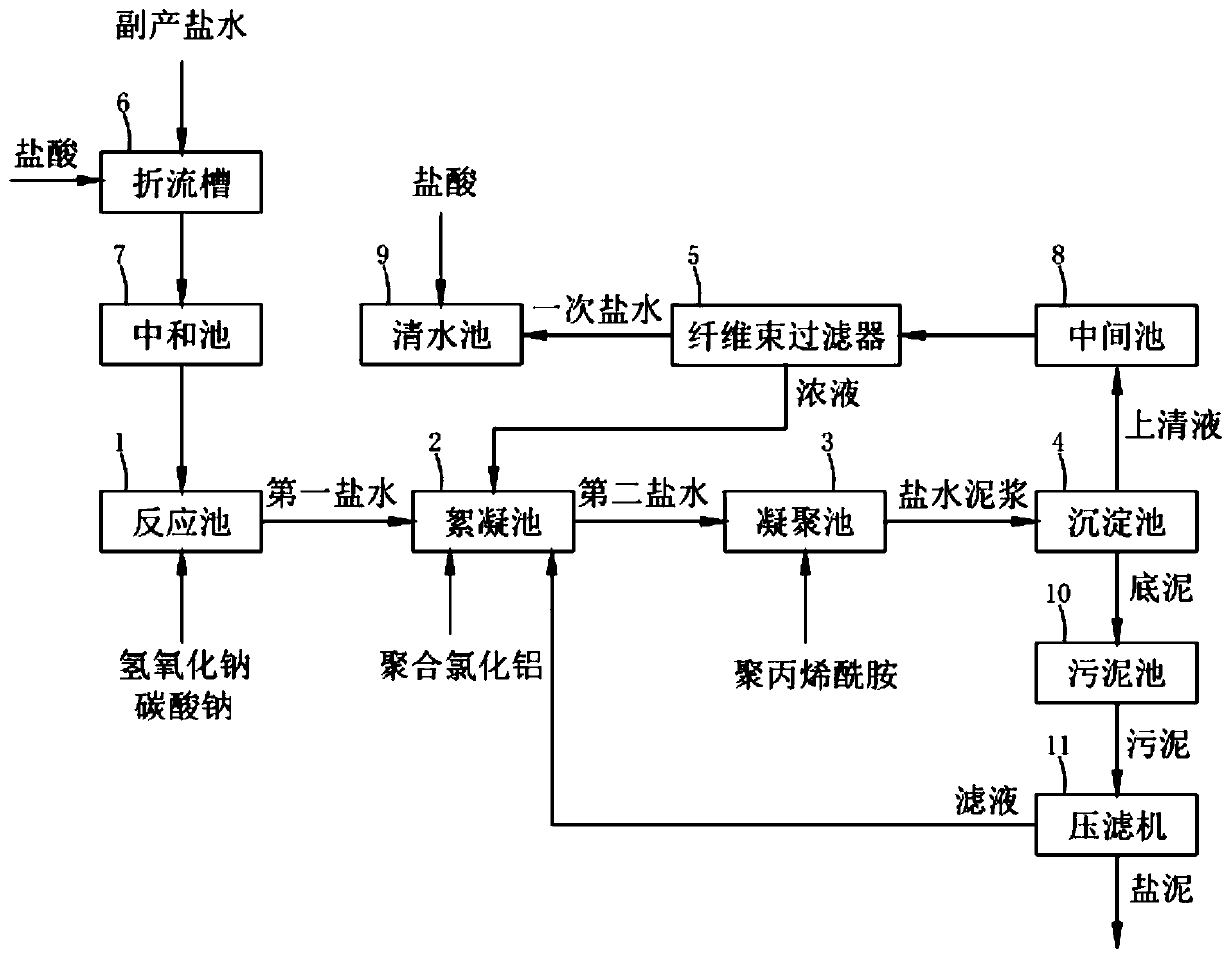

Refining system and method for by-product brine

InactiveCN110697935APromote formationEasy to separateSludge treatmentWater contaminantsAluminium chloridePhysical chemistry

The invention discloses a refining method of by-product brine, which comprises the following steps of: generating by-product brine in the production process of magnesium hydroxide; adding sodium hydroxide and sodium carbonate to by-product brine to form calcium carbonate precipitate and magnesium hydroxide precipitate to obtain a first brine; adding polyaluminum chloride into the first brine for bridging to generate flocs to obtain the second brine; adding polyacrylamide to the second brine so that flocs particles gather to obtain brine slurry; The brine slurry is precipitated to obtain supernatant and bottom slurry, and filtering the supernatant to obtain primary brine. In the present invention, sodium hydroxide and soda ash are used as precipitants, the magnesium ions are precipitated asmagnesium hydroxide, the calcium ions are precipitated as calcium carbonate, polyaluminium chloride plays a flocculation bridging role to generate flocs and precipitate, while polyacrylamide plays acoagulation role to aggregate flocs particles. The addition of polyacrylamide and polyaluminium chloride promotes the formation and separation of precipitates, so that calcium and magnesium ions in by-product salt water are removed as much as possible.

Owner:QINGHAI SALT LAKE IND

La, Ce and Nd-containing aluminum titanium alloy wire and production method thereof

The invention relates to a multielement aluminum titanium alloy wire, which comprises the following components by weight: 94-97% of Al; 0.05-1% of V; 2-5% of Ti; 0.01-0.8% of La, 0.01-0.4% of Ce, and 0.01-0.2% of Nd, wherein the total amount of the three rare-earth elements is 0.03-0.96%, the total amount of the trace additive elements is not greater than 1%, the resistivity of the aluminum titanium alloy wire is 2.0-6.0muomega.cm, the specific weight of the aluminum titanium alloy wire is 2.60-2.75g / cm<3>, and the percentage elongation of the aluminum titanium alloy wire is 10-25%.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Ce-Nd-containing zinc-aluminum alloy wire and production method thereof

The invention relates to a multi-element zinc-aluminum alloy wire. The multi-element zinc-aluminum alloy wire comprises, by weight percent, 15%-69% of Al, 0.2-3% of Si, 0.1-5% of Mg, 0.01-0.7% of Ce, 0.01-0.2% of Nd, not more than 1% of added microelements, and the balance of Zn, wherein the two rare earth elements have a total amount of 0.02-0.76%. The zinc-aluminum alloy wire has a resistivity of 2.0-6.0 Mu omega / cm, a specific gravity of 3.18-5.69g / cm<3>, and an elongation of 10-25%. The multi-element zinc-aluminum alloy wire is widely applicable to ships, power towers, large storage tanks, underground pipelines and facilities such as tunnel frames, and has broad application prospect.

Owner:JIANGSU LINLONG NEW MATERIALS

La and Pr-containing aluminum titanium alloy wire and production method thereof

The invention relates to an a multielement aluminum titanium alloy wire, which comprises the following components in weight percentage: 94-97% of Al; 0.05-1% of V; 2-5% of Ti; 0.01-0.7% of La, and 0.01-0.2% of Pr, wherein the total amount of the two rare-earth elements is 0.02-0.76%, the total amount of trace additional elements is not greater than 1%, the resistivity of the aluminum titanium alloy wire is 2.0-6.0 muomega*cm, the specific weight of the aluminum titanium alloy wire is 2.60-2.75g / cm<3>, and the percentage elongation of the aluminum titanium alloy wire is 10-25%.

Owner:JIANGSU LINLONG NEW MATERIALS

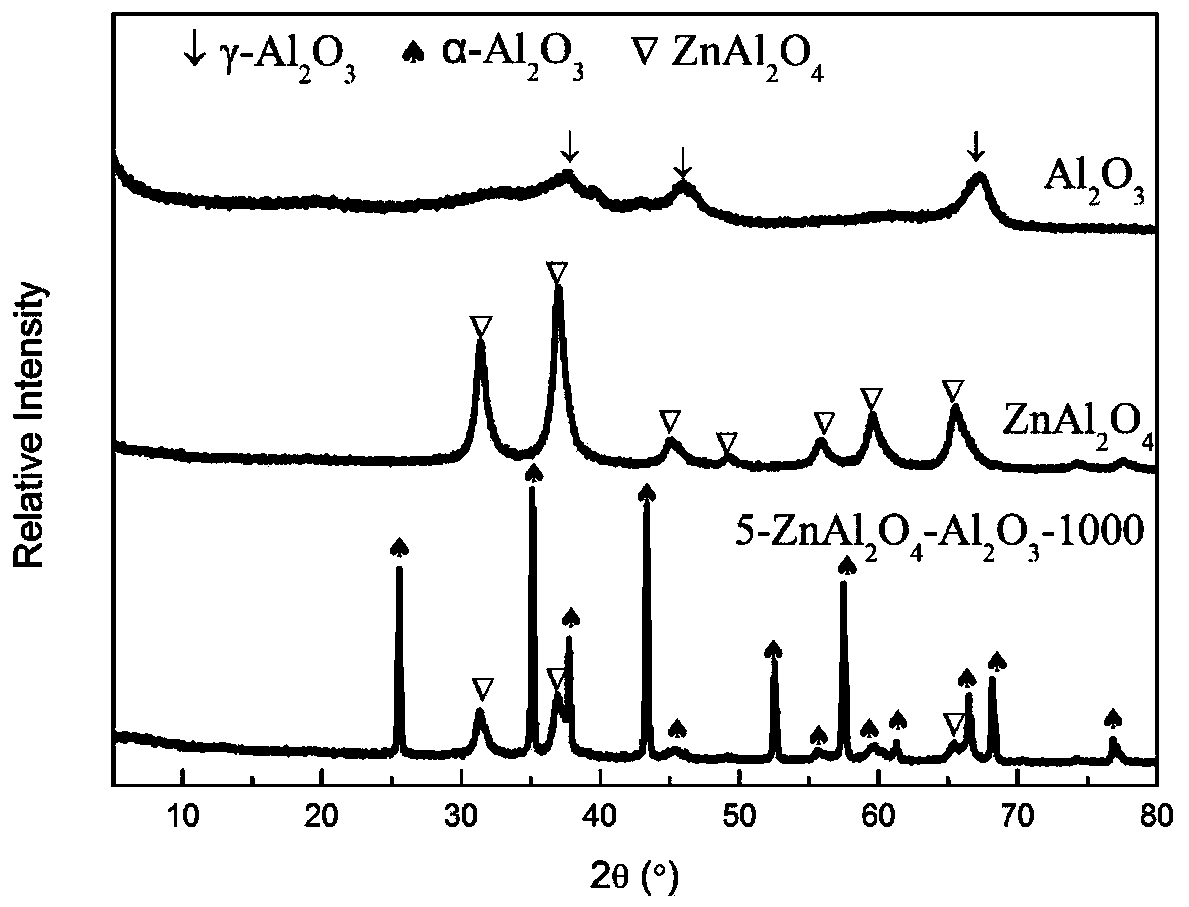

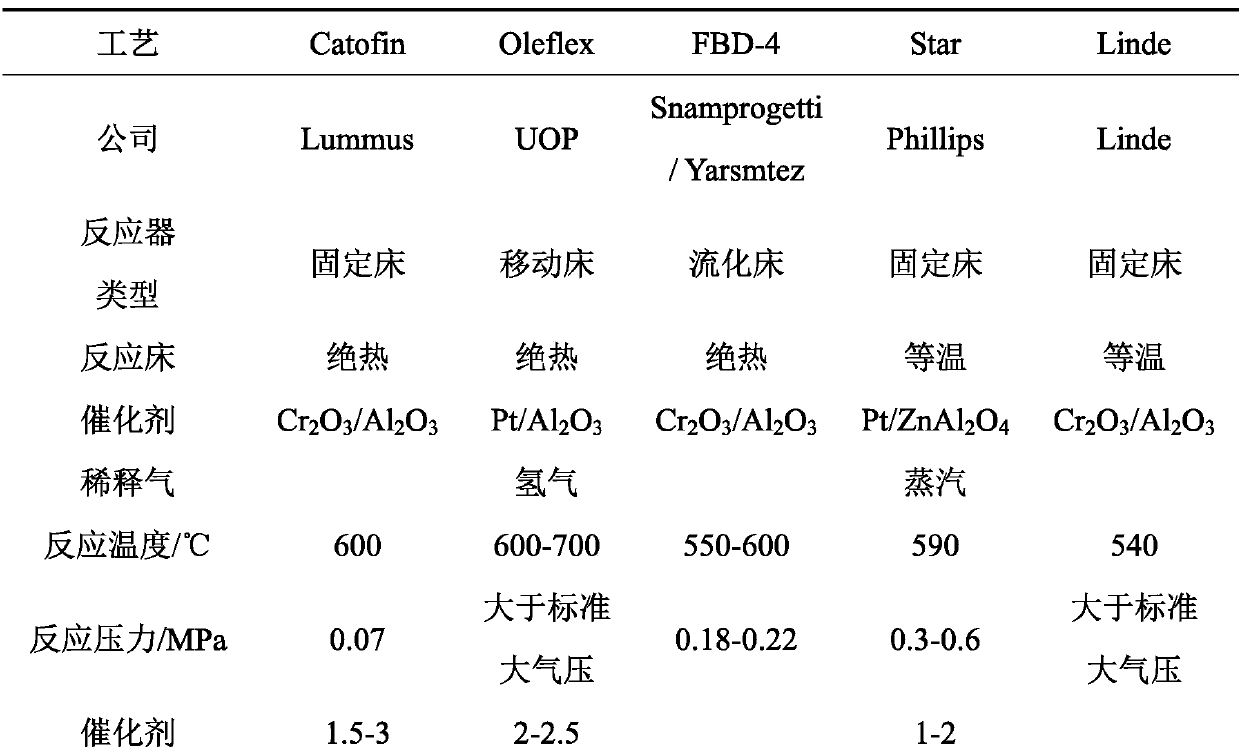

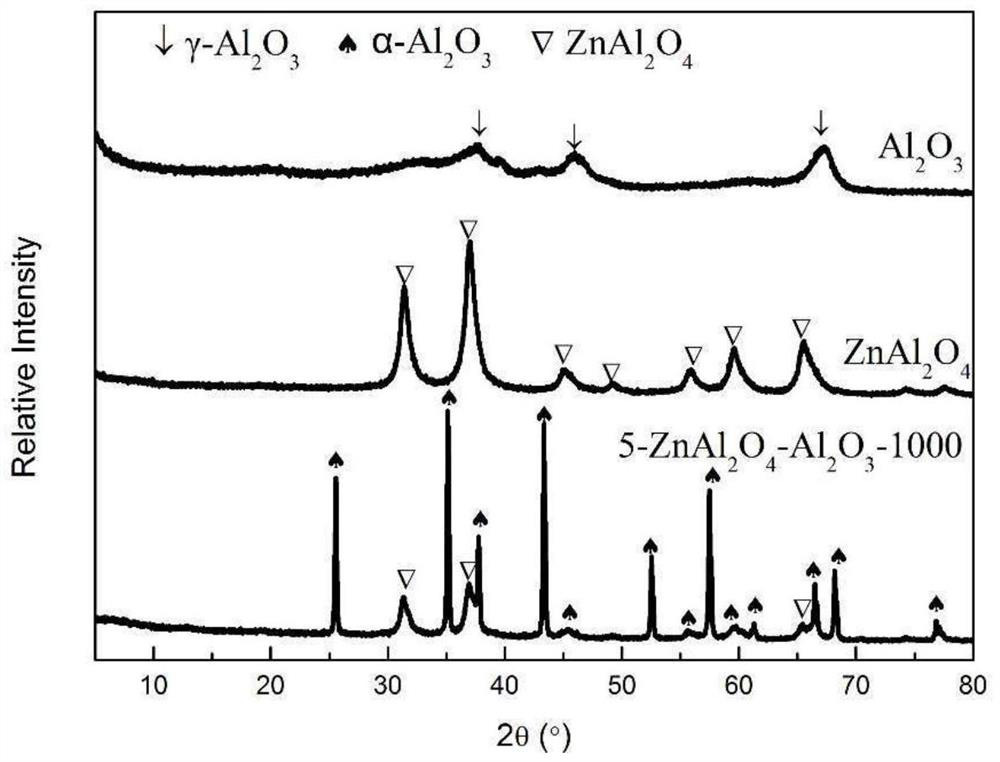

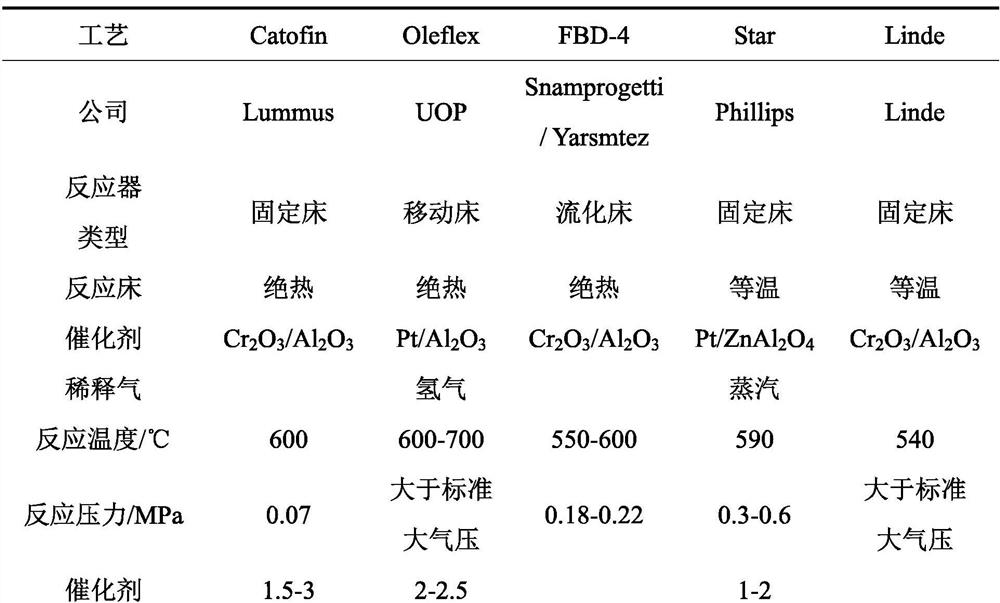

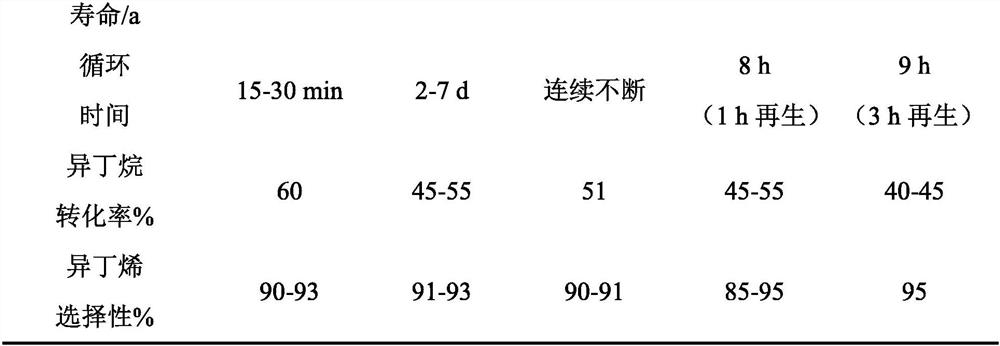

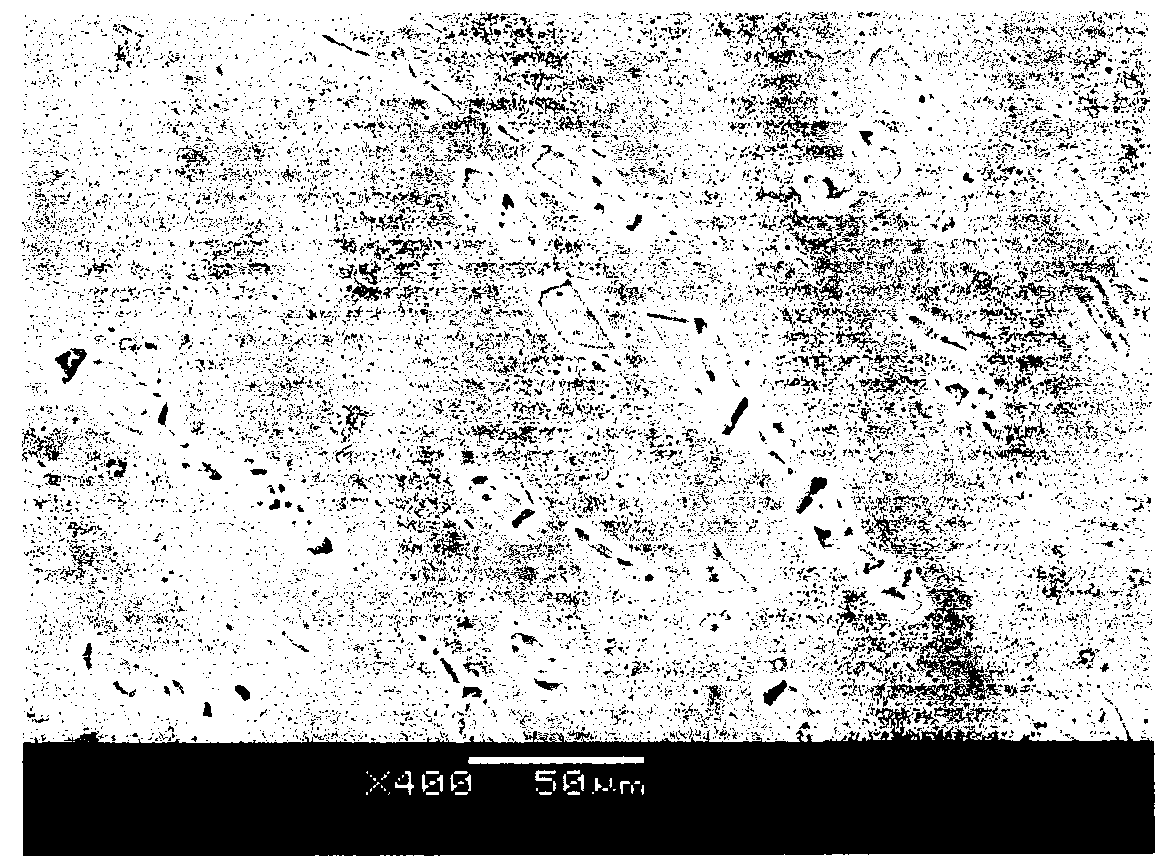

Isobutane dehydrogenation catalyst and preparation method and application thereof

ActiveCN111437813AHigh selectivityImprove stabilityHeterogenous catalyst chemical elementsCatalystsPtru catalystPhysical chemistry

The invention discloses an isobutane dehydrogenation catalyst and a preparation method and application thereof. According to the catalyst, alpha-Al2O3 spheres which are subjected to zinc oxide surfacemodification and heat treatment to form a thin-layer zinc aluminate spinel structure are used as a carrier; a first active layer and a second active layer which are different from each other are sequentially arranged on the surface of the carrier from inside to outside, the first active layer is a platinum oxide layer or a tin oxide layer, and the second active layer is a platinum oxide layer ora tin oxide layer. The isobutane dehydrogenation catalyst has high selectivity, stability and activity, good high-temperature stability, strong carbon deposition resistance and low relative deactivation rate, the active components are distributed on the carrier in an eggshell structure, the utilization rate of the active components is increased and the catalyst has a good industrial application prospect.

Owner:XIAMEN UNIV

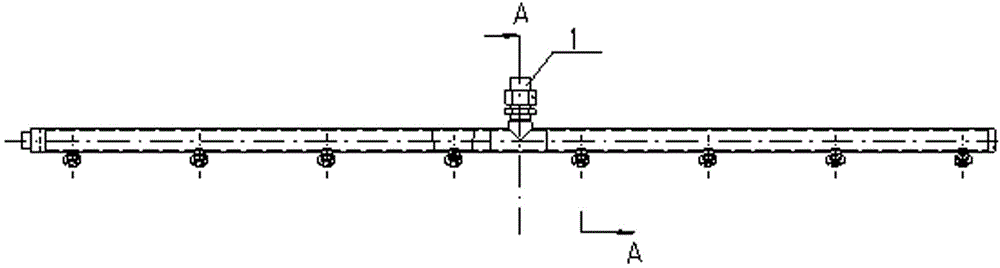

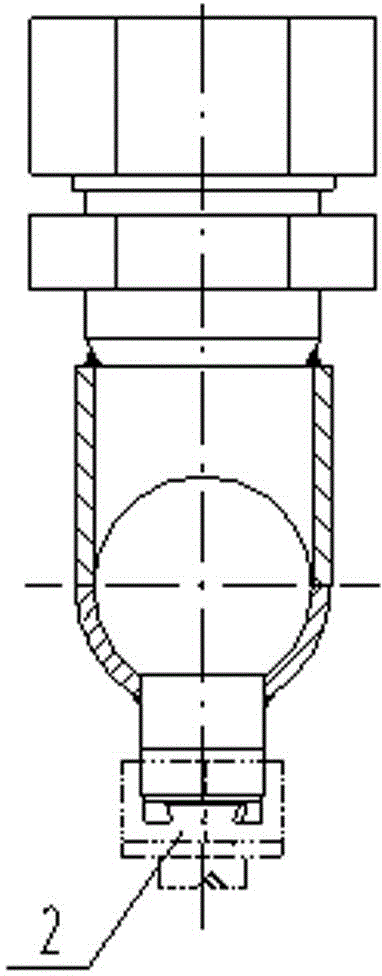

Device for improving surface quality of vertical roll of vertical rolling mill

InactiveCN108723092AQuality improvementEasy to mix and sprayRollsCleaning using gasesEngineeringOil water

The invention belongs to the technical field of vertical rolls, and discloses a device for improving surface quality of a vertical roll of a vertical rolling mill. The device comprises an oil water mixing and spraying structure and a roll surface spraying-blowing structure, wherein the output end of the oil water mixing and spraying structure is arranged towards the roll surface of the vertical roll; covering height of a sprayed and covered surface is greater than or equal to height of a contact surface between the vertical roll and plate blank; the roll surface spraying-blowing structure comprises a spraying-blowing spray head, a gas-flow pipeline and a gas source; the spraying-blowing spray head is connected with the gas source through the gas-flow pipeline to obtain compressed air; andthe spraying-blowing spray head is arranged towards the roll surface of the vertical roll for spraying and blowing compressed air to the roll surface. The device for improving surface quality of the vertical roll of the vertical rolling mill provided by the invention can improve the surface quality of the vertical roll.

Owner:BEIJING SHOUGANG CO LTD

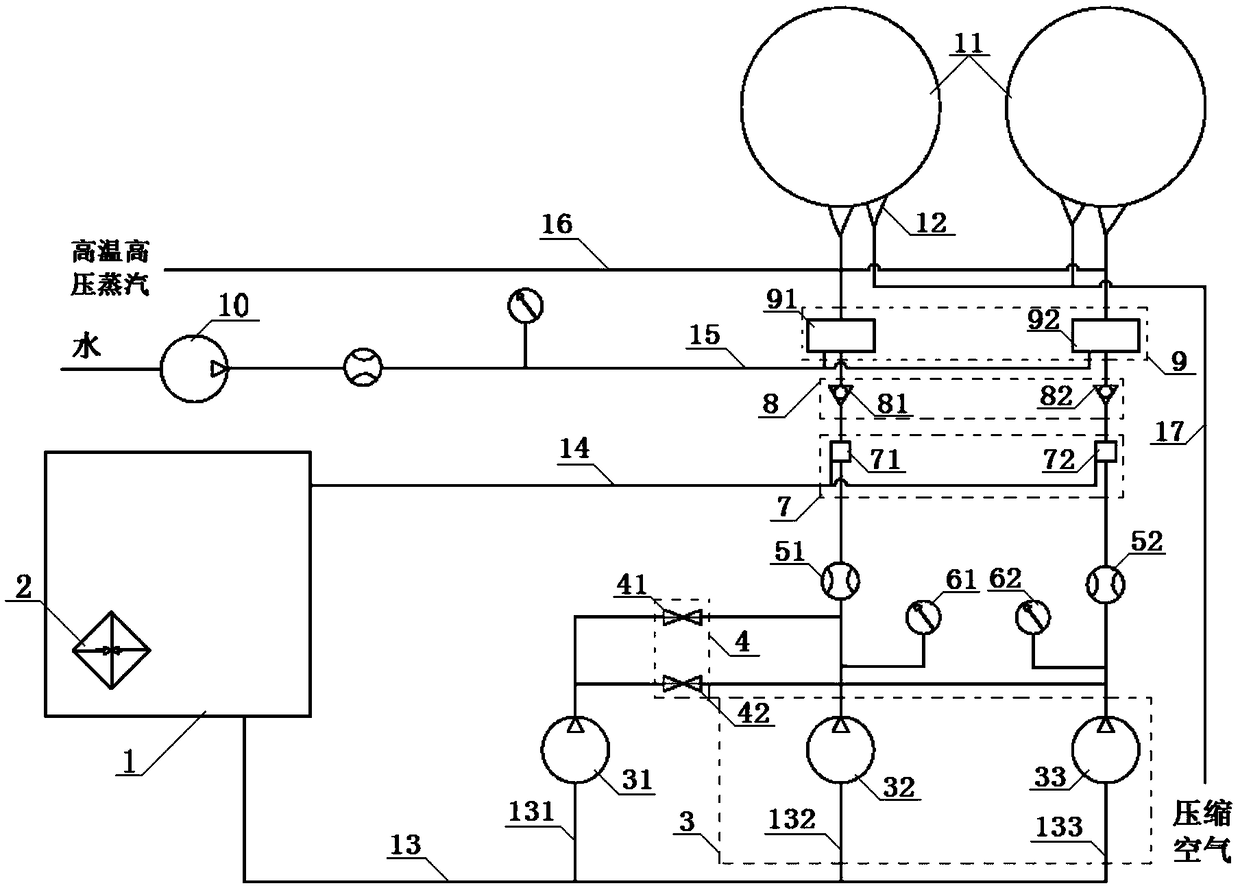

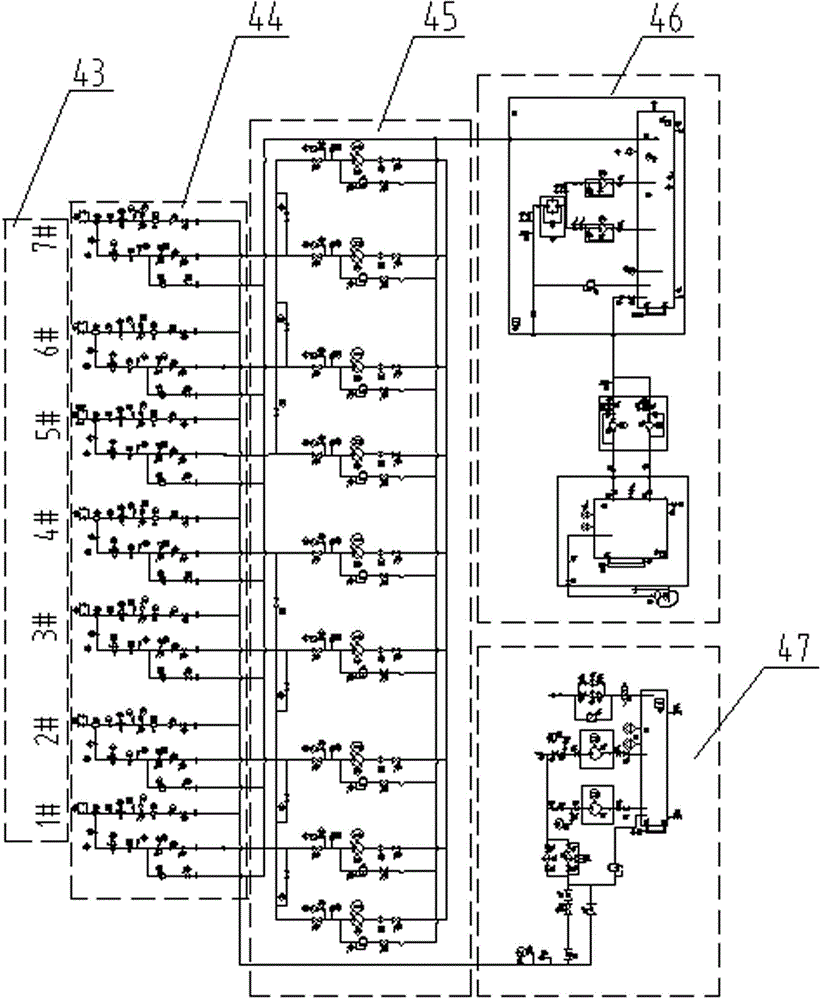

Technological rolling lubricating system of finish rolling mill for hot-rolled strip steel

InactiveCN103599943AReduce coefficient of frictionReduce oxygen concentrationRollsMetal rolling arrangementsStress conditionsStrip steel

The invention discloses a technological rolling lubricating system of a finish rolling mill for hot-rolled strip steel. The lubricating system comprises a water supply device, an oil supply device and a metering pump station. The oil supply device is connected with oil inlets of the metering pump station by working oil pumps on the oil supply device, the water supply device is connected to a water inlet of an oil and water mixing control unit, the metering pump station is connected to an oil inlet of the oil and water mixing control unit, and the oil and water mixing control unit is connected with a lubricating header. The technological rolling lubricating system has the advantages that the stability of the shape of a roller can be improved, and the service life of the roller can be effectively prolonged; stressed conditions of the surface of the roller can be relieved, accordingly, the roller replacement frequency can be reduced, and the operation time of the roller can be prolonged; rolling force can be reduced, so that electric energy can be saved; the quality of the surface of the strip steel can be improved, so that the pickling ability can be improved after the strip steel is subjected to hot rolling; after rolling oil is applied, a friction coefficient of the inside of a deformation zone is reduced, so that the rolling pressure can be decreased.

Owner:QIDONG ZHONGYE LUBRICATION HYDRAULIC PRESSURE EQUIP

Aluminum-titanium (Al-Ti) alloy wire containing lanthanum (La) and cerium (Ce) and method for manufacturing same

ActiveCN102605218BImprove passivation effectStrong expandabilityMolten spray coatingTrace elementCerium

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Aluminum-titanium (Al-Ti) alloy wire containing praseodymium (Pr) and neodymium (Nd) and method for manufacturing same

ActiveCN102605215BImprove passivation effectStrong expandabilityMolten spray coatingRare earthTitanium

The invention relates to a multi-component aluminum-titanium (Al-Ti) alloy wire which comprises the following components in percent by weight: 94-97% of Al, 0.05-1% of vanadium (V), 2-5% of Ti, 0.01-0.2% of praseodymium (Pr), 0.01-0.2% of neodymium (Nd). The total percent by weight of the two rear-earth elements which are Pr and Nd is 0.02-0.40%, and the total percent by weight of the added traceelements is 1% or less. The Al-Ti alloy wire has the resistivity of 2.0-6.0 muohm.cm, the specific weight of 2.60-2.75g / cm<3> and the elongation rate of 10-25%.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

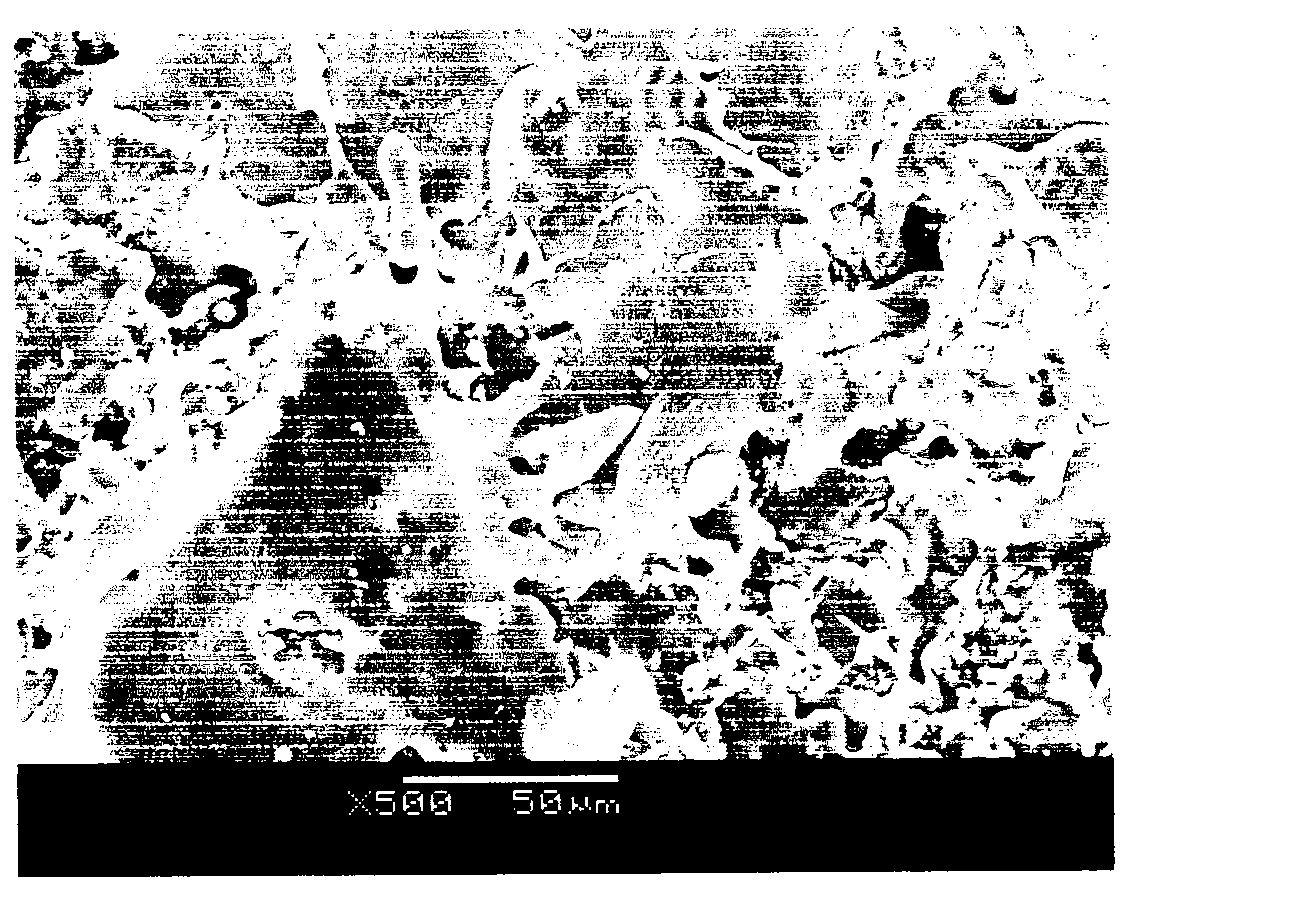

Zinc-aluminum alloy wire containing La, Ce, Pr and Nd and production method thereof

ActiveCN102703760BFast growthOvercome the defect of increased segregationMolten spray coatingRare-earth elementZinc

The invention relates to a multi-element zinc-aluminum alloy wire. The multi-element zinc-aluminum alloy wire comprises, by weight percent, 15%-69% of Al, 0.2-3% of Si, 0.1-5% of Mg, 0.01-0.8% of La, 0.01-0.4% of Ce, 0.01-0.2% of Pr, 0.01-0.2% of Nr, not more than 1% of added microelements, and the balance of Zn, wherein the four rare earth elements have a total amount of 0.04-1.2%. The zinc-aluminum alloy wire has a resistivity of 2.0-6.0 Mu omega / cm, a specific gravity of 3.18-5.69g / cm<3>, and an elongation of 10-25%. The multi-element zinc-aluminum alloy wire is widely applicable to ships, power towers, large storage tanks, underground pipelines and facilities such as tunnel frames, and has broad application prospect.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Aluminum-titanium alloy wire containing Ce and Nd, and manufacturing method thereof

The invention relates to a multi-element aluminum-titanium alloy wire comprising components of, by weight: 94%-97% of aluminum Al, 0.05%-1% of vanadium V, 2%-5% of titanium Ti, 0.01-0.7% of cerium Ce, and 0.01-0.2% of neodymium Nd, and no more than 1% of trace additive elements. A total amount of the two rare earth elements is 0.02-0.76%. The resistivity of the aluminum-titanium alloy wire is 2.0-6.0muohm*cm. The specific weight of the aluminum-titanium alloy wire is 2.60-2.75g / cm<3>, and the extensibility of the aluminum-titanium alloy wire is 10-25%.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

La-Ce-Pr-containing zinc-aluminum alloy wire and manufacturing method thereof

The invention relates to a multielement zinc-aluminum alloy wire which comprises the following components in percentage by weight: 15-69% of Al, 0.2-3% of Si, 0.1-5% of Mg, 0.01-0.8% of La, 0.01-0.4% of Ce, 0.01-0.2% of Pr (the total amount of the three rare-earth elements is 0.03-0.96%), at most 1% of microelements and the balance of Zn. The resistivity of the zinc-aluminum alloy wire is 2.0-6.0mu omega.cm, the specific gravity of the zinc-aluminum alloy wire is 3.18-5.69 is g / cm<3>, and the elongation percentage of the zinc-aluminum alloy wire is 10-25%; and thus, the zinc-aluminum alloy wire can be widely used in ships, power supply towers, large-size storage tanks, underground pipelines, tunnel frames and other facilities, and has very wide application prospects.

Owner:JIANGSU LINLONG NEW MATERIALS

A kind of isobutane dehydrogenation catalyst and its preparation method and application

ActiveCN111437813BSimple processReduce manufacturing costHeterogenous catalyst chemical elementsCatalystsPtru catalystPhysical chemistry

The invention discloses an isobutane dehydrogenation catalyst and its preparation method and application. The catalyst uses zinc oxide surface modification and heat treatment to form a thin-layer zinc aluminate spinel structure α-Al 2 o 3 The ball is a carrier, and the surface of the carrier has a first active layer and a second active layer that are different from each other in sequence from the inside to the outside, the first active layer is a platinum oxide layer or a tin oxide layer, and the second active layer is a platinum oxide layer or tin oxide layer. The isobutane dehydrogenation catalyst of the present invention has high selectivity, stability and activity, good high temperature stability, strong anti-coking ability, relatively slow deactivation rate, and the active components are distributed on the carrier in an eggshell structure On the one hand, the utilization rate of active components is improved, and it has better industrial application prospects.

Owner:XIAMEN UNIV

Aluminum and titanium alloy wire containing La, Ce and Pr and manufacturing method thereof

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

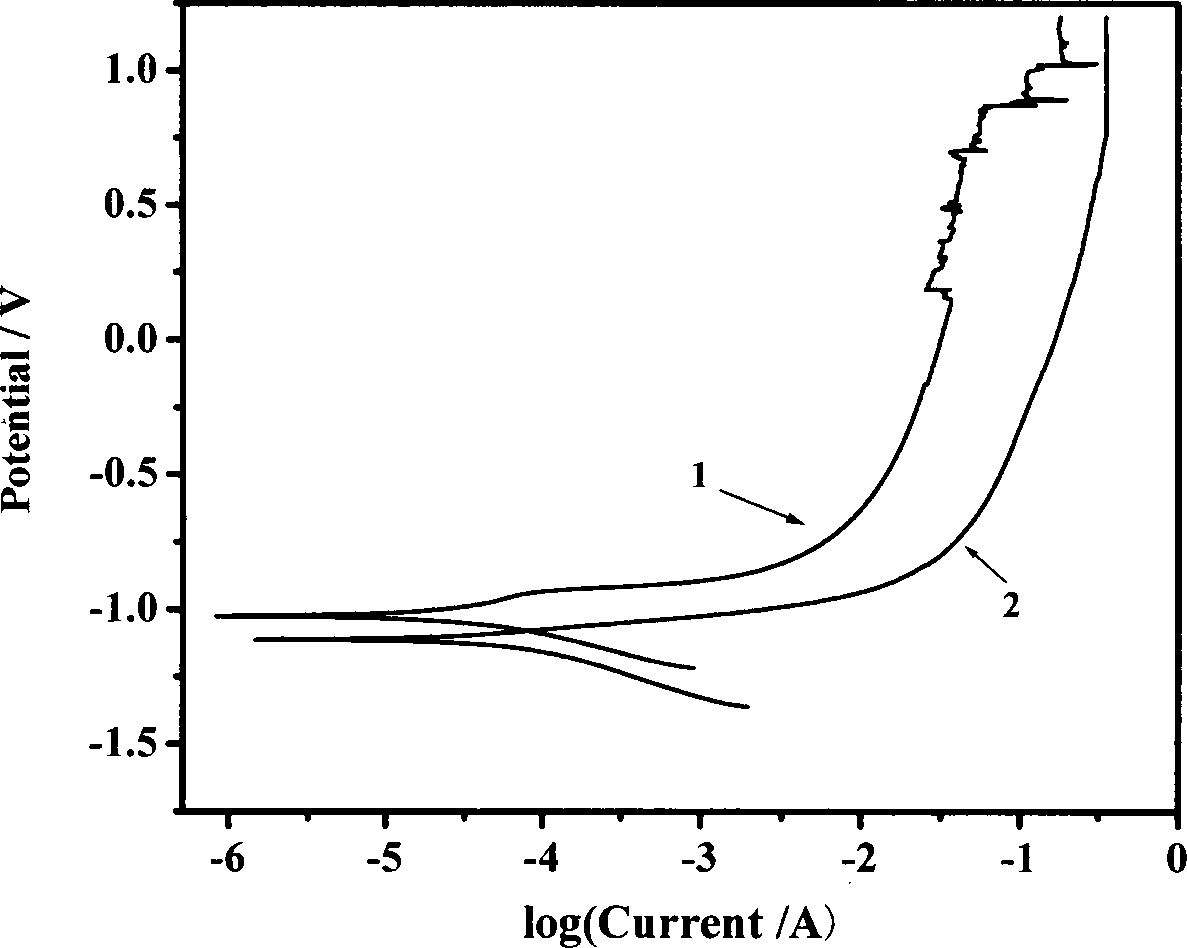

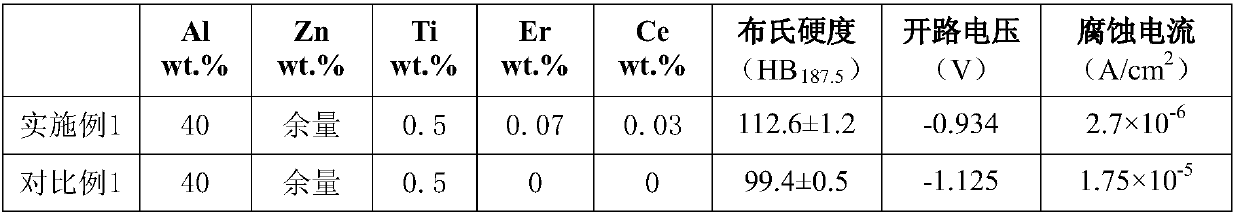

Rare-earth-containing zinc-aluminum-titanium alloy wire and preparation method and application thereof

The invention discloses a rare-earth-containing zinc-aluminum-titanium alloy wire and a preparation method and application thereof. The zinc-aluminum-titanium alloy wire comprises, by weight, 15-40% of aluminum, 0.5-2.0% of titanium, 0.02-0.2% of rare earth element cerium and rare earth element erbium, less than or equal to 0.025% of impurities, and the balance zinc. The mass ratio of the rare earth element cerium to the rare earth element erbium is 3:7. According to the rare-earth-containing zinc-aluminum-titanium alloy wire and the preparation method and application thereof, by adding into the rare earth element cerium and the rare earth element erbium, the corrosion resistance is improved, meanwhile, the zinc-aluminum-titanium alloy wire has the advantages of being high in hardness, low in price and the like and can replace traditional zinc wires to be applied to the fields of spraying anti-corrosion engineering and the like, and in addition, a rare-earth zinc-aluminum-titanium alloy hot coating has excellent adhesion force and good physical and mechanical properties and corrosion resistance; the average annual corrosion rate of the rare-earth zinc-aluminum-titanium alloy hot coating is higher than that of a hot spraying zinc coating, a zinc-aluminum alloy coating, a zinc-aluminum pseudo-alloy coating and other coatings, and compared with aluminum and other aluminum alloy hot spraying metal layers, the anodic protection of the rare-earth zinc-aluminum-titanium alloy hot coating is obviously improved; and the whole wire machining and manufacturing process is simple, quick and low in cost.

Owner:广西高城新材料科技有限公司

Zinc-aluminum alloy wire containing La, Ce and Nd and production method thereof

The invention relates to a multi-element zinc-aluminum alloy wire. The multi-element zinc-aluminum alloy wire comprises, by weight percent, 15%-69% of Al, 0.2-3% of Si, 0.1-5% of Mg, 0.01-0.8% of Ce, 0.01-0.2% of Pr, 0.01-0.2% of Nd, not more than 1% of added microelements, and the balance of Zn, wherein the three rare earth elements have a total amount of 0.03-0.92%. The zinc-aluminum alloy wire has a resistivity of 2.0-6.0 Mu omega / cm, a specific gravity of 3.18-5.69g / cm<3>, and an elongation of 10-25%. The multi-element zinc-aluminum alloy wire is widely applicable to ships, power towers, large storage tanks, underground pipelines and facilities such as tunnel frames, and has broad application prospect.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

La and Nd-containing aluminum titanium alloy wire and production method thereof

ActiveCN102605217BImprove passivation effectStrong expandabilityMolten spray coatingRare-earth elementTitanium alloy

The invention relates to a multielement aluminum titanium alloy wire, which comprises the following components by weight: 94-97% of Al; 0.05-1% of V; 2-5% of Ti; 0.01-0.7% of La, and 0.01-0.2% of Nd, wherein the total amount of the two rare-earth elements is 0.02-0.76%, the total amount of the trace additive elements is not greater than 1%, the resistivity of the aluminum titanium alloy wire is 2.0-6.0 muomega.cm, the specific weight of the aluminum titanium alloy wire is 2.60-2.75g / cm<3>, and the percentage elongation of the aluminum titanium alloy wire is 10-25%.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

La-Nd-containing zinc-aluminum alloy wire and production method thereof

The invention relates to a multi-element zinc-aluminum alloy wire. The multi-element zinc-aluminum alloy wire comprises, by weight percent, 15%-69% of Al, 0.2-3% of Si, 0.1-5% of Mg, 0.01-0.7% of La, 0.01-0.2% of Nd, not more than 1% of added microelements, and the balance of Zn, wherein the two rare earth elements have a total amount of 0.02-0.76%. The zinc-aluminum alloy wire has a resistivity of 2.0-6.0 Mu Omega / cm, a specific gravity of 3.18-5.69g / cm<3>, and an elongation of 10-25%. The multi-element zinc-aluminum alloy wire is widely applicable to ships, power supply towers, large storage tanks, underground pipelines and facilities such as tunnel frames, and has broad application prospect.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

A rare earth-containing zinc-aluminum-titanium alloy wire and its preparation method and application

The invention discloses a rare-earth-containing zinc-aluminum-titanium alloy wire and a preparation method and application thereof. The zinc-aluminum-titanium alloy wire comprises, by weight, 15-40% of aluminum, 0.5-2.0% of titanium, 0.02-0.2% of rare earth element cerium and rare earth element erbium, less than or equal to 0.025% of impurities, and the balance zinc. The mass ratio of the rare earth element cerium to the rare earth element erbium is 3:7. According to the rare-earth-containing zinc-aluminum-titanium alloy wire and the preparation method and application thereof, by adding into the rare earth element cerium and the rare earth element erbium, the corrosion resistance is improved, meanwhile, the zinc-aluminum-titanium alloy wire has the advantages of being high in hardness, low in price and the like and can replace traditional zinc wires to be applied to the fields of spraying anti-corrosion engineering and the like, and in addition, a rare-earth zinc-aluminum-titanium alloy hot coating has excellent adhesion force and good physical and mechanical properties and corrosion resistance; the average annual corrosion rate of the rare-earth zinc-aluminum-titanium alloy hot coating is higher than that of a hot spraying zinc coating, a zinc-aluminum alloy coating, a zinc-aluminum pseudo-alloy coating and other coatings, and compared with aluminum and other aluminum alloy hot spraying metal layers, the anodic protection of the rare-earth zinc-aluminum-titanium alloy hot coating is obviously improved; and the whole wire machining and manufacturing process is simple, quick and low in cost.

Owner:广西高城新材料科技有限公司

Ce-Nd-containing zinc-aluminum alloy wire and production method thereof

The invention relates to a multi-element zinc-aluminum alloy wire. The multi-element zinc-aluminum alloy wire comprises, by weight percent, 15%-69% of Al, 0.2-3% of Si, 0.1-5% of Mg, 0.01-0.7% of Ce, 0.01-0.2% of Nd, not more than 1% of added microelements, and the balance of Zn, wherein the two rare earth elements have a total amount of 0.02-0.76%. The zinc-aluminum alloy wire has a resistivity of 2.0-6.0 Mu omega / cm, a specific gravity of 3.18-5.69g / cm<3>, and an elongation of 10-25%. The multi-element zinc-aluminum alloy wire is widely applicable to ships, power towers, large storage tanks, underground pipelines and facilities such as tunnel frames, and has broad application prospect.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Multi-element aluminum-titanium alloy wire and manufacturing method thereof

ActiveCN102534317BImprove passivation effectStrong expandabilityMolten spray coatingRare-earth elementTitanium

The invention relates to a multi-element aluminum-titanium alloy wire, which comprises the following components in percentage by weight: 94 to 97 percent of Al, 0.05 to 1 percent of V, 2 to 5 percent of titanium, 0.02 to 1.2 percent of at least two rare-earth elements, and less than 1 percent of minor additive elements. The aluminum-titanium alloy wire has the resistivity of 2.0-6.0 mu ohm.cm, the specific weight of 2.60-2.75g / cm<3> and the elongation of 10-25 percent, and is used in facilities such as ship decks, municipal works, pedestrian passageways, tunnel frames and the like.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

La, Ce and Nd-containing aluminum titanium alloy wire and production method thereof

The invention relates to a multielement aluminum titanium alloy wire, which comprises the following components by weight: 94-97% of Al; 0.05-1% of V; 2-5% of Ti; 0.01-0.8% of La, 0.01-0.4% of Ce, and 0.01-0.2% of Nd, wherein the total amount of the three rare-earth elements is 0.03-0.96%, the total amount of the trace additive elements is not greater than 1%, the resistivity of the aluminum titanium alloy wire is 2.0-6.0muomega.cm, the specific weight of the aluminum titanium alloy wire is 2.60-2.75g / cm<3>, and the percentage elongation of the aluminum titanium alloy wire is 10-25%.

Owner:JIANGSU LINLONG NEW MATERIALS CO LTD

Preparation method and application of aluminum zinc phosphate molecular sieve catalyst

ActiveCN113117741ASimple processReduce manufacturing costMolecular sieve catalystsCatalyst activation/preparationMolecular sieveO-Phosphoric Acid

The invention discloses a preparation method and application of an aluminum zinc phosphate molecular sieve catalyst. The preparation method comprises the following steps of: (1) adding orthophosphoric acid into deionized water, then adding soluble zirconium salt or soluble titanium salt and a dispersing agent, heating to 50-60 DEG C while stirring, then adding soluble zinc salt, and after the soluble zinc salt is completely dissolved, adding pseudo-boehmite, uniformly stirring, adding a template agent, adjusting the pH value to 5-6 by using diluted hydrochloric acid, and continuously stirring to form a uniform jelly; (2) transferring the jelly into a homogeneous reaction kettle, aging the jelly while stirring, and then heating for constant-temperature crystallization reaction to obtain a crystallized product; (3) washing and filtering the crystallized product, drying the crystallized product, transferring the crystallized product into a calcining furnace, heating to 550-600 DEG C, and keeping the temperature for 4-6 hours to obtain molecular sieve raw powder; and (4) adding the molecular sieve raw powder into an aqueous solution added with 10-20% of aluminum sol to further obtain the aluminum zinc phosphate molecular sieve catalyst. The method has the advantages of being simple in technological process, low in production cost, safe, environmentally friendly, suitable for industrial large-scale production and the like.

Owner:XIAMEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com