Multi-element aluminum-titanium alloy wire and manufacturing method thereof

An aluminum-titanium alloy and multi-component technology, which is applied in the field of thermal spraying multi-component aluminum-titanium alloy materials and their manufacturing, can solve the problems of ineffective application of thermally sprayed zinc-aluminum alloy wire, affecting the protective performance of the wire, and limited technical application. Achieve the effect of enhancing anti-stripping ability, accelerating the growth rate of crystal nucleus, and good expandability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

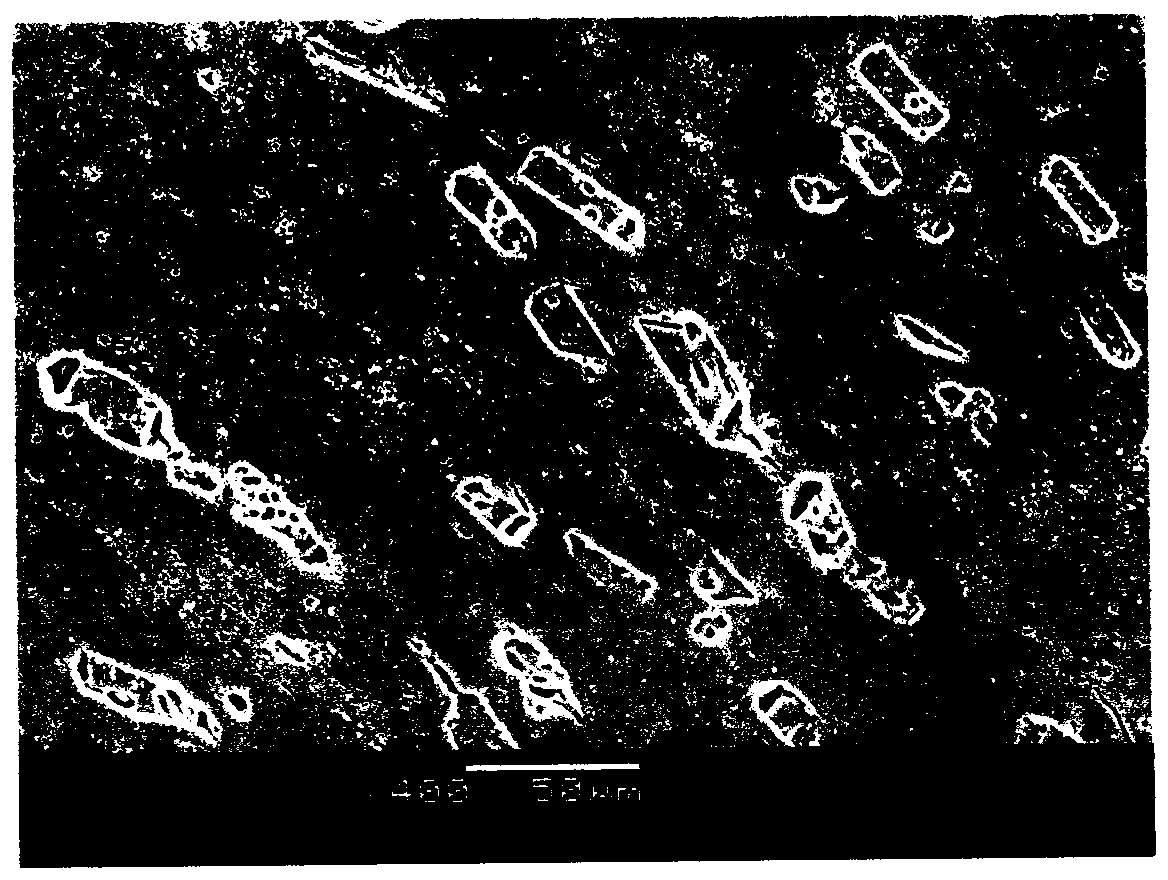

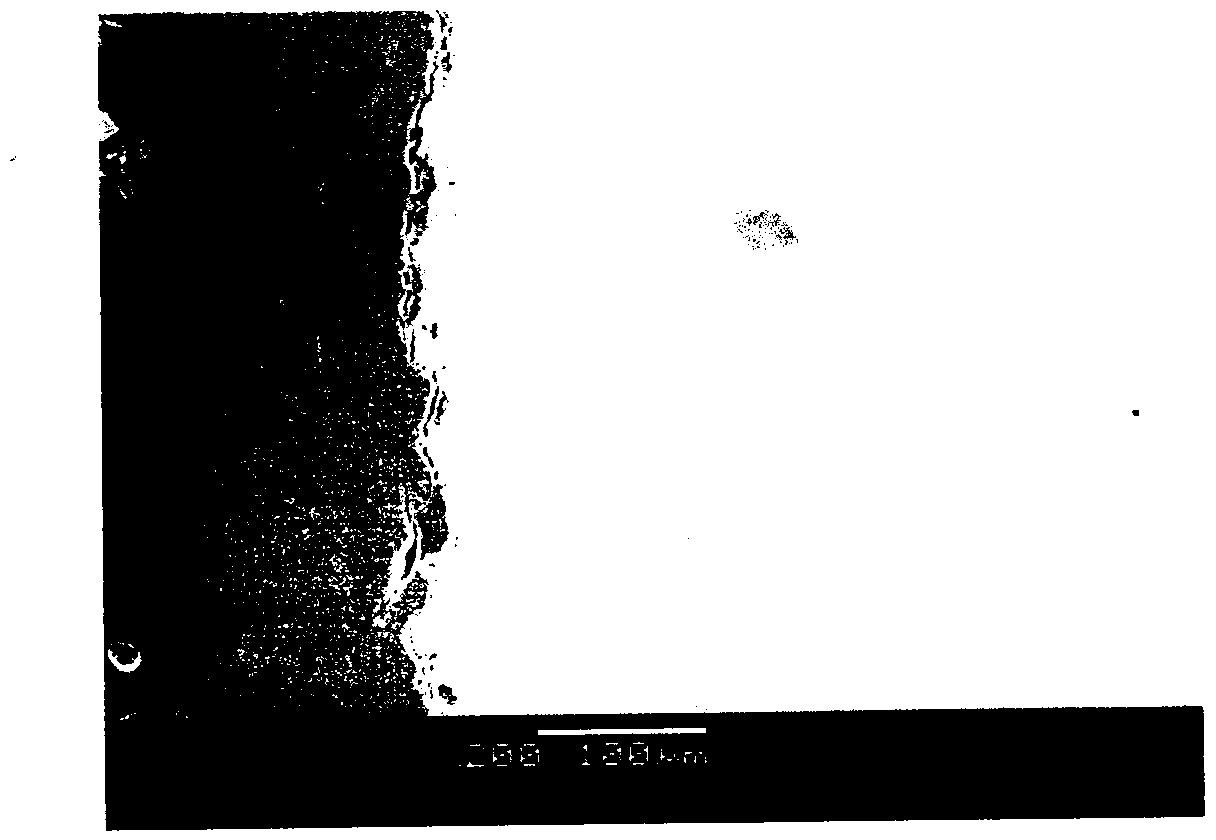

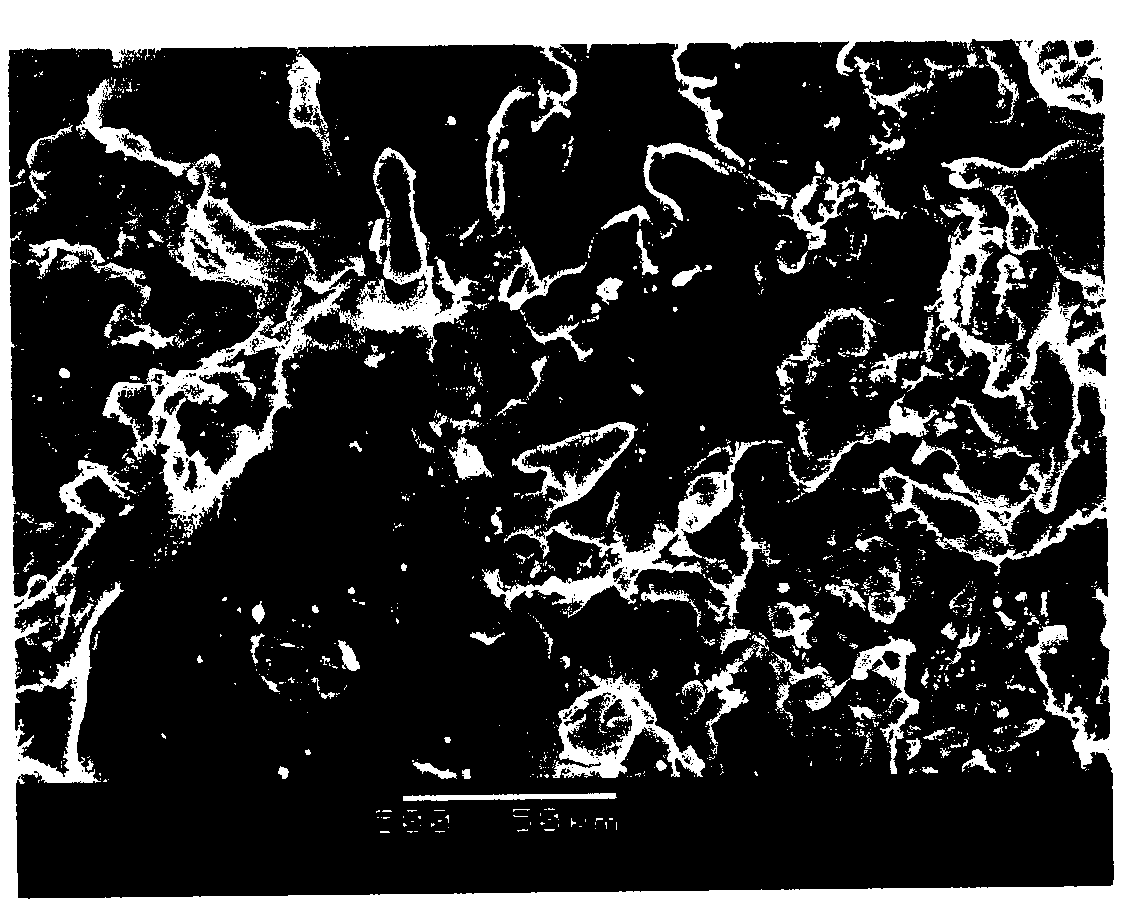

Image

Examples

Embodiment Construction

[0044] The multi-element aluminum-titanium alloy wire of the present invention, by weight percentage: its composition is: Aluminum Al: 94%-97%; Vanadium V: 0.05%-1%; Titanium Ti: 2%-5%; at least two kinds of rare earths The total amount of elements: 0.02-1.2%, the total amount of trace elements not exceeding 1%, the resistivity of the aluminum-titanium alloy wire is 2.0-6.0μΩ·cm, and the specific gravity of the aluminum-titanium alloy wire is 2.60-2.75 g / cm 3 , the elongation rate of the aluminum-titanium alloy wire is 10-25%.

[0045] What needs to be specially explained here is that a very important improvement of the technical solution of the present invention is that the resistivity of the aluminum-titanium alloy wire is 2.0-6.0 μΩ·cm, and the specific gravity of the aluminum-titanium alloy wire is 2.60-2.75 g / cm 3 , the elongation rate of the aluminum-titanium alloy wire is 10-25%. These excellent properties are far beyond the alloy wires under the same conditions in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com