La, Ce and Nd-containing aluminum titanium alloy wire and production method thereof

A technology of aluminum-titanium alloy and rare earth elements, applied in the field containing La, to achieve the effect of improving oxidation resistance, improving strength and plasticity, and reducing hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

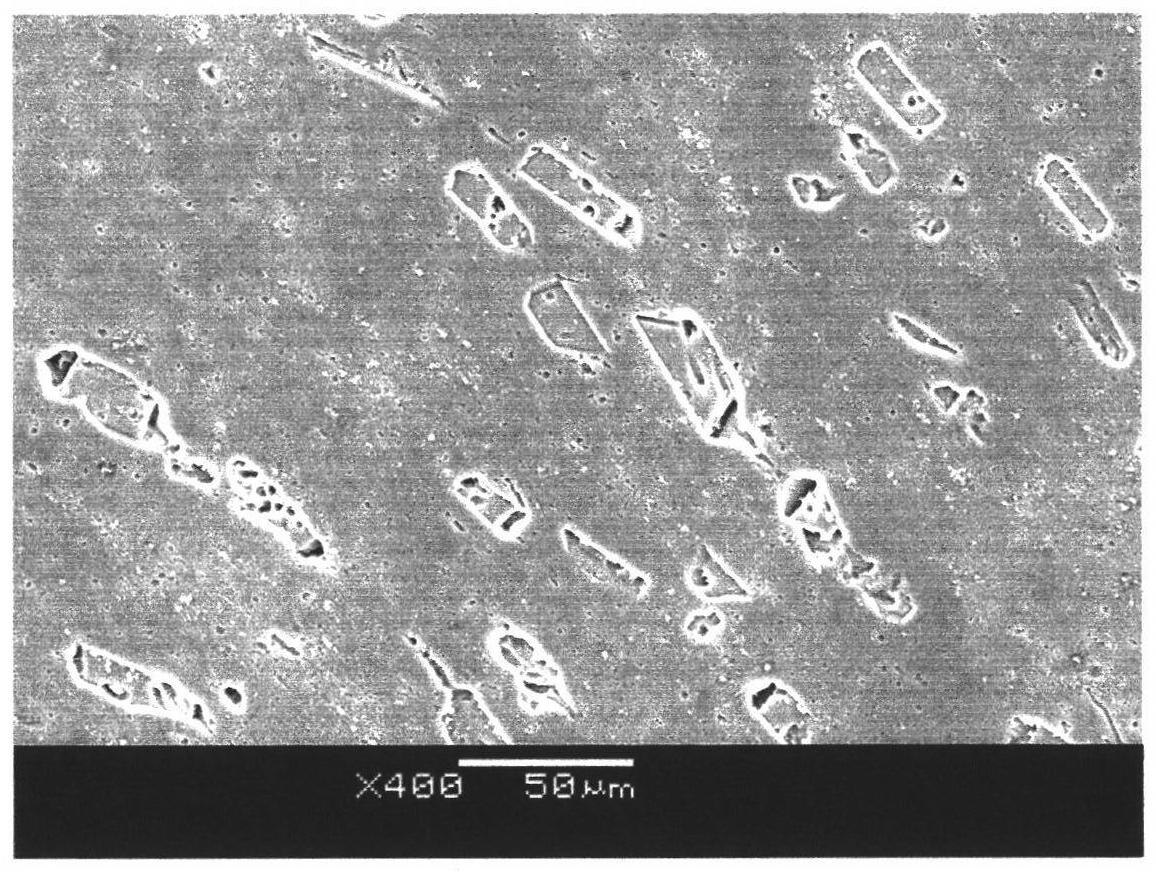

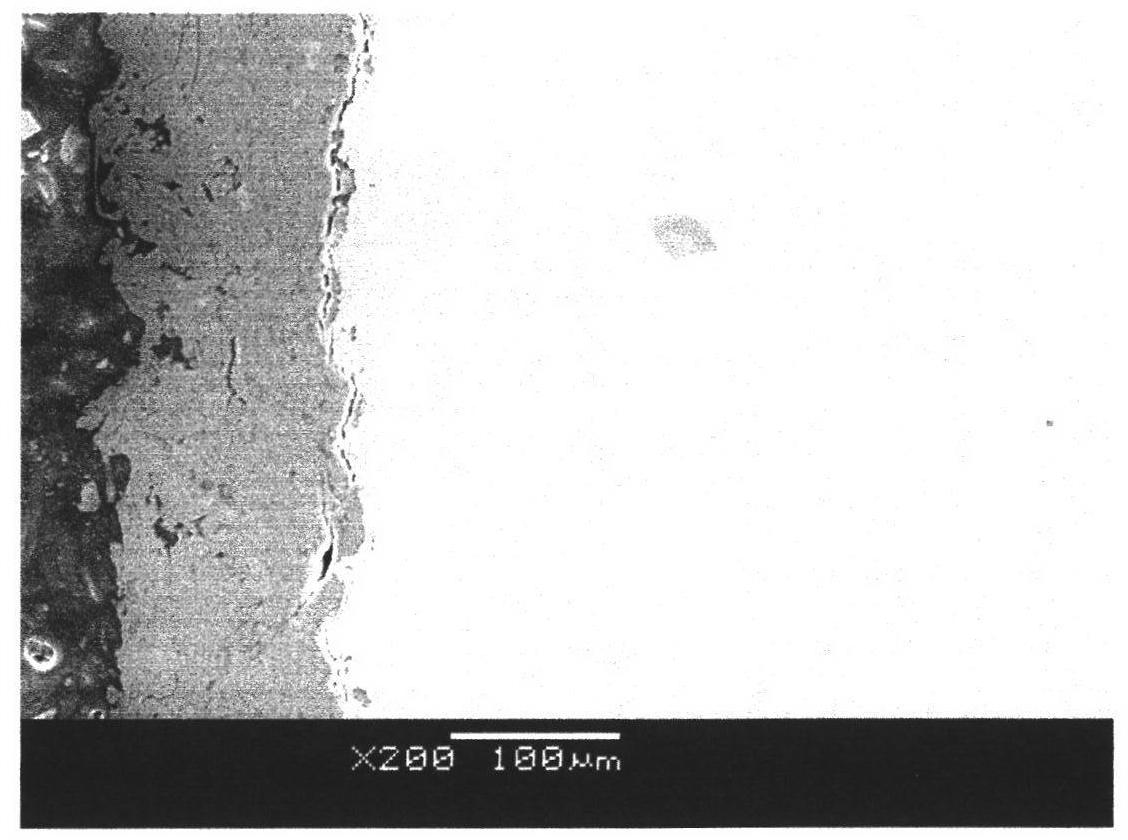

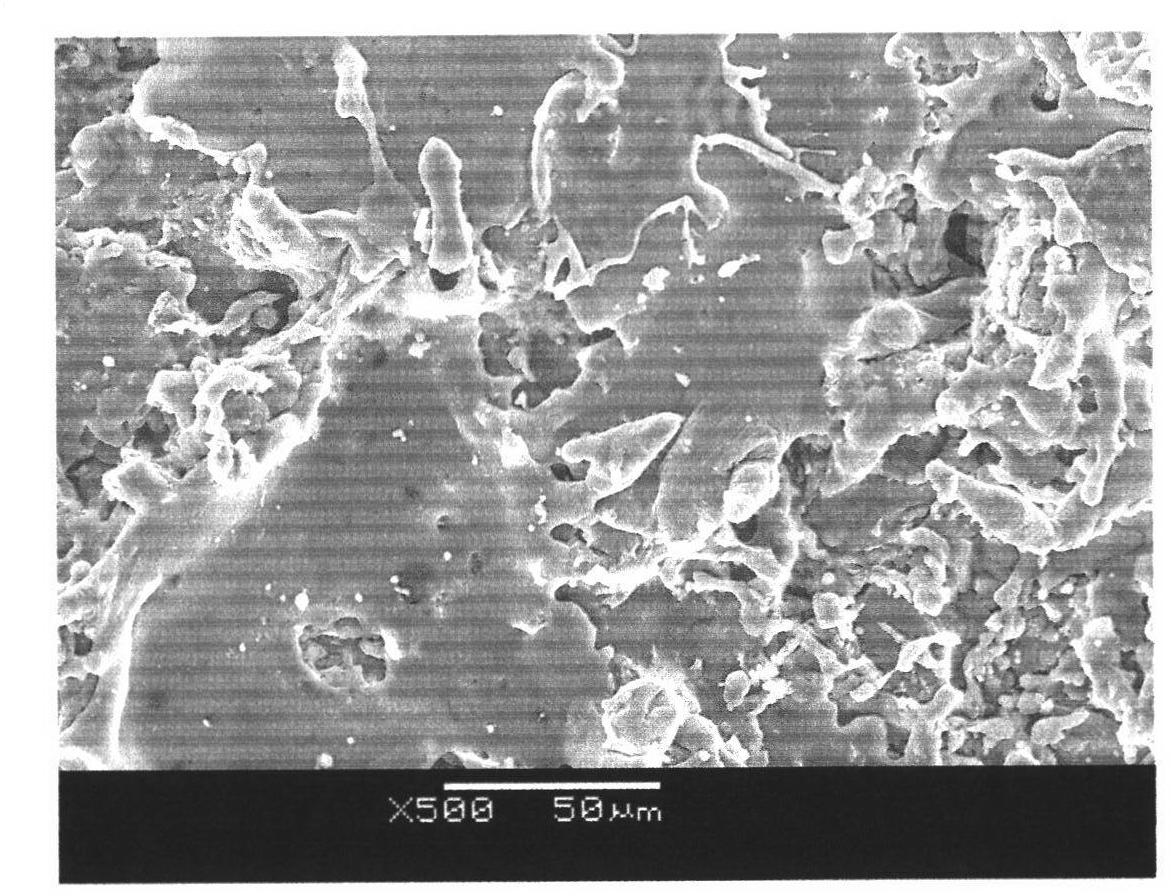

[0044] The multi-element aluminum-titanium alloy wire of the present invention has the following components by weight percentage: aluminum Al: 94%-97%; vanadium V: 0.05%-1%; titanium Ti: 2%-5%; lanthanum La: 0.01% -0.8%, cerium Ce: 0.01-0.4%, neodymium Nd: 0.01-0.2%, the total amount of the three rare earth elements: 0.03-1.05%, the total amount does not exceed 1% trace elements, the aluminum-titanium alloy The resistivity of the wire is 2.0-6.0μΩ·cm, and the specific gravity of the aluminum-titanium alloy wire is 2.60-2.75g / cm 3 , the elongation rate of the aluminum-titanium alloy wire is 10-25%.

[0045] What needs to be specially explained here is that a very important improvement of the technical solution of the present invention is that the resistivity of the aluminum-titanium alloy wire is 2.0-6.0 μΩ·cm, and the specific gravity of the aluminum-titanium alloy wire is 2.60-2.75 g / cm 3 , the elongation rate of the aluminum-titanium alloy wire is 10-25%. These excellent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com