Rare-earth-containing zinc-aluminum-titanium alloy wire and preparation method and application thereof

A technology of titanium alloy wire and zinc-aluminum, applied in the application field of zinc-aluminum-titanium alloy wire containing rare earth elements Ce and Er and its preparation, and thermal spraying anti-corrosion coating, which can solve the problems of unreported application and achieve low price , high strength, and the effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

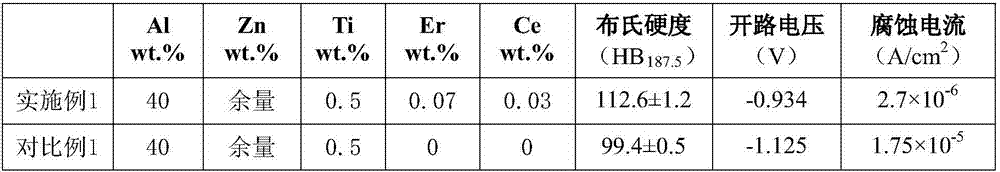

Embodiment 1

[0037] A rare earth-containing zinc-aluminum-titanium alloy wire, by weight percentage, contains aluminum (Al): 40%; the total amount of two rare earth elements is 0.1%, and the mass ratio of erbium (Er) to cerium (Ce) is 7:3 ; Titanium (Ti): 0.5%, and the rest are zinc (Zn) and impurities whose total amount is not more than 0.025%.

Embodiment 2

[0044] A rare earth-containing zinc-aluminum-titanium alloy wire, by weight percentage, contains aluminum (Al): 40%; the total amount of two rare earth elements is 0.1%, and the mass ratio of erbium (Er) to cerium (Ce) is 7:3 ; Titanium (Ti): 2%, the rest are zinc (Zn) and impurities with a total amount not greater than 0.025%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com