Automatic coal dredging device for raw coal conveying system in thermal power plant

A technology for thermal power plants and conveying systems, applied in the directions of transportation and packaging, packaging, containers, etc., can solve the problems of large operation and maintenance workload, unstable combustion of boilers, and high labor intensity, so as to ensure normal coal supply and safe operation. Reliable, economical results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

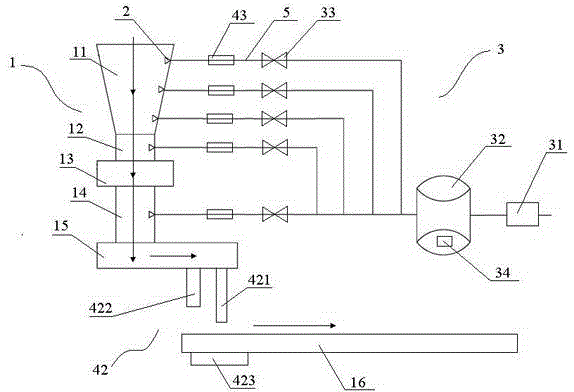

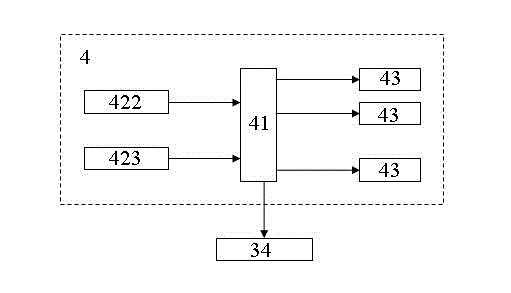

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0021] An automatic coal dredging device used in the raw coal conveying system of a thermal power plant, its structure diagram is as follows figure 1 shown. It includes an air supply system 3, a control system 4 and several air injection ports 2, wherein the air injection ports 2 are installed on the inner walls of each equipment of the raw coal conveying system 1, and the air injection ports 2 communicate with the air supply system 3 through the air pipe 5, and the air supply system 3. Change the working state under the control of the control system 4.

[0022] The raw coal conveying system described in this embodiment includes a raw coal hopper 11, a variable diameter pipe 12, a gate valve 13, a coal drop pipe 14, a coal feeder 15, a conveyor belt 16, and a gas injection port that are sequentially arranged in accordance with the raw coal conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com