Pre-nucleation reactor of nanometer calcium carbonate and preparation technology of the nanometer calcium carbonate

A nano-calcium carbonate and a preparation process technology are applied to the crystal nucleus preforming reactor of nano-calcium carbonate and the field of preparation thereof, which can solve the problems of insignificant effect and easy blocking of the crystal nucleus preforming device, and achieve a wide range of process control parameters. , not easy to block, the effect of small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

[0025] The crystal nucleus preforming reactor provided by the invention includes a jet flow section and a gel breaking section, and the jet flow section and the gel breaking section are sealed and connected by screws. A specific embodiment of the present invention is as figure 1 As shown, there is a slurry inlet 1 at the front end of the jet section, an air inlet 2 at the side, and a bell mouth at the rear end, and the airtight connection between the bell mouth and the gel breaking section.

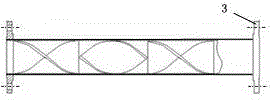

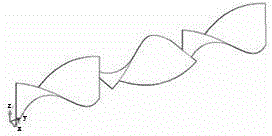

[0026] Such as figure 2 As shown, the gel breaking section can be a schematic diagram of a SK type static mixer with a slurry outlet 3 opened. Its internal units such as image 3 As shown, it is a spiral plate twisted 180° or 270°.

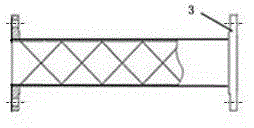

[0027] Such as Figure 4 As shown, the gel breaking section can also be a schematic diagram of an SD type static mixer with a slurry outlet 3 opened...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com