Active carbon filter

An activated carbon filter and filter technology, applied in the direction of adsorption water/sewage treatment, etc., can solve the problems of high carbon column, low tank equipment, large water consumption, etc., and achieve simple operation, prevent filter material from hardening, and single flushing water Small amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

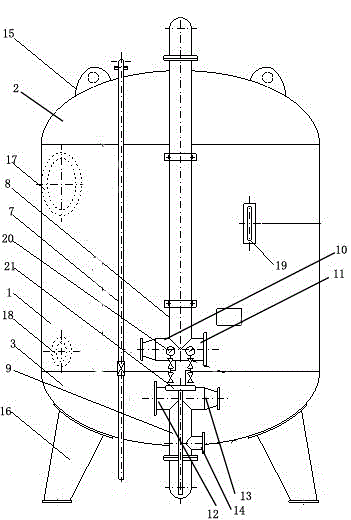

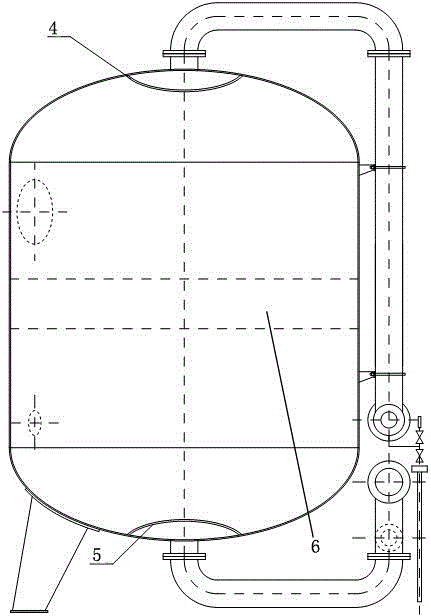

[0017] Such as figure 1 As shown, an activated carbon filter according to the present invention includes a filter body composed of a cylinder body 1, an upper head 2, and a lower head 3; the top of the filter body is provided with a water distribution device 4 , the bottom is provided with a perforated plate 5; the inside of the filter body is also provided with a water collection filter layer 6; the upper left end of the outer wall of the filter body is provided with a flange manhole 17, the lower left end is provided with a discharge hole 18, and the outer wall of the right end A peep mirror 19 is provided; the top of the filter body is fixed with a steam exhaust pipe 7 and a water inlet pipe system 8, and the bottom end is connected with an outlet pipe system 9; the water inlet pipe system 8 is composed of a water inlet pipe 10 and a backwash drain pipe 11 constitutes; said outlet pipe system 9 is made up of backwash inlet pipe 12, outlet pipe 13 and positive air drain pipe...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap