Method for processing arsenic-antimony fume by using replacement-reduction method so as to recover arsenic and antimony

A technology of arsenic recovery and reduction method, applied in the direction of improving process efficiency, can solve problems such as hindering process development, and achieve the effects of simple and easy operation, low economic cost and effective recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

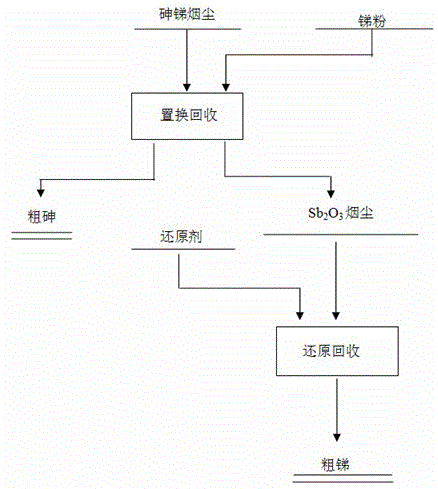

[0021] like figure 1 Shown, this replacement-reduction process handles the method for reclaiming arsenic and antimony from arsenic and antimony dust, and its concrete steps are as follows:

[0022] (1) Recovering arsenic by replacement method: the mass ratio of arsenic and antimony fume to arsenic and antimony dust (arsenic and antimony dust includes the following mass percentage components: arsenic content is 5%, antimony content is 30%) and antimony powder is 3: 1 Add antimony powder, and then replace and react at a temperature of 500°C for 30 minutes. During this process, the volatilized dust of antimony trioxide is collected. After the reaction is completed, crude arsenic will be obtained. The antimony powder has a purity of 95% and a particle size of 40 For this purpose, antimony trioxide volatilized dust is collected by bag dust collection;

[0023] (2) Recovery of antimony by reduction method: add reducing agent to the volatile dust of antimony trioxide collected in st...

Embodiment 2

[0026] like figure 1 Shown, this replacement-reduction process handles the method for reclaiming arsenic and antimony from arsenic and antimony dust, and its concrete steps are as follows:

[0027] (1) Recover arsenic by replacement method: add arsenic and antimony fume to arsenic and antimony dust (arsenic and antimony fume includes the following components in mass percentage: arsenic content is 20%, antimony content is 60%) according to the mass ratio of arsenic and antimony fume to antimony powder is 10: 1. Add antimony powder, and then replace and react at 800°C for 120 minutes. During this process, collect the volatilized dust of antimony trioxide. After the reaction is completed, crude arsenic will be obtained. The purity of antimony powder is 99%, and the particle size is 100 For this purpose, antimony trioxide volatilized dust is collected by bag dust collection;

[0028] (2) Recovery of antimony by reduction method: add reducing agent to the volatile dust of antimony...

Embodiment 3

[0031] like figure 1 Shown, this replacement-reduction process handles the method for reclaiming arsenic and antimony from arsenic and antimony dust, and its concrete steps are as follows:

[0032] (1) Recovering arsenic by replacement method: the mass ratio of arsenic and antimony fume to arsenic and antimony dust (arsenic and antimony dust includes the following mass percentage components: arsenic content is 15%, antimony content is 45%) and antimony powder is 9: 1. Add antimony powder, and then replace and react at 600°C for 90 minutes. During this process, the purity of the antimony powder is 97%, and the particle size is 80 mesh. Collect the volatile dust of antimony trioxide. After the reaction is completed, crude arsenic will be obtained , in which the volatile fumes of antimony trioxide are collected by bag dust collection;

[0033] (2) Recovery of antimony by reduction method: add reducing agent to the volatile dust of antimony trioxide collected in step (1) accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com