Frequency spectrum harmonic wave treatment method for improving dimensional stability of aluminum matrix composite

An aluminum matrix composite material and dimensional stability technology, applied in the field of metal matrix composite materials, can solve the problems of reducing material dimensional stability, low efficiency, long construction period, etc., and achieve a significant reduction in residual stress, low energy consumption, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The material selected in this example is a high-volume SiCp / Al (55%) composite material, the SiC particles of the reinforcement are evenly distributed in the Al matrix, and the sample is a rod with a diameter of 5 mm and a length of 25 mm.

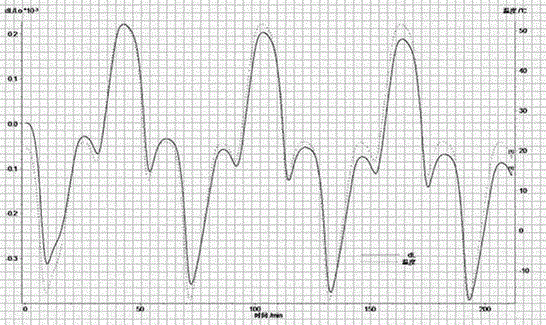

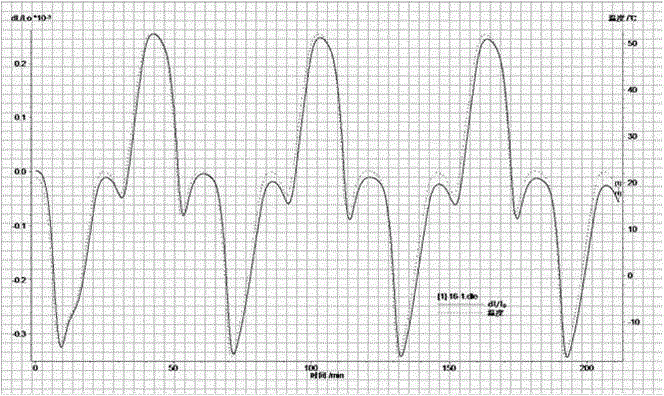

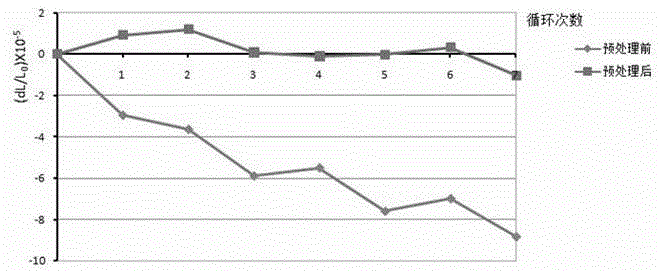

[0030] Specific implementation method: First, carry out spectral harmonic aging treatment on a batch of samples. Specific processing steps: In the first step, select an exciter with an exciting force of 65KN, and fix the sample on a vibration exciter equipped with the exciter. on the platform. The second step is to find five optimal excitation frequencies and two alternative excitation frequencies through Fourier analysis. The vibration speeds are: 4048rpm, 4278rpm, 4408rpm, 4575rpm, 4720rpm, 4905rpm, 5134rpm. In the third step, the vibration time is 18 min, 16 min, 16 min, 14 min, 14 min, 14 min, and 12 min in sequence, and vibration treatment is performed. Another batch of samples used for comparison was not treated; secondly, th...

Embodiment 2

[0032] The material selected in this example is a high-volume SiCp / Al (45%) composite material, and the reinforcement SiC is evenly distributed in the Al matrix. For the experimental parts, see Figure 4 , Figure 5 .

Embodiment approach

[0033] Specific implementation method: first, in the part Figure 4 Select 7 points evenly distributed on the surface, and measure their residual stress; secondly, carry out harmonic aging treatment on the parts. On the vibrating platform equipped with the exciter. The second step is to find five optimal excitation frequencies and two alternative excitation frequencies through Fourier analysis. The vibration speeds are: 3000rpm, 3298rpm, 3487rpm, 3613rpm, 3852rpm, 3996rpm, 4207rpm. In the third step, the vibration time is 22min, 20min, 20min, 18min, 18min, 16min, and 16min in turn, and the vibration treatment is performed; again, the residual stress of the 7 points selected above is measured at the same position. The specific experimental data are shown in Table 1; finally, according to the data in Table 1, Figure 6 ,pass Figure 6 We can see that after spectral harmonic aging treatment, the purpose of reducing the peak residual stress and homogenizing residual stress of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com