Hydraulic control system for quick water inlet gates of hydroelectric power station

A hydraulic control system and water inlet technology, which is applied in fluid pressure actuation system testing, fluid pressure actuation devices, servo motors, etc., can solve the problem of inability to repair and maintain a single fast gate control system, and cannot meet the requirements of power redundancy and reliability In order to achieve the effects of good scalability and flexibility, reasonable design structure and guaranteed reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

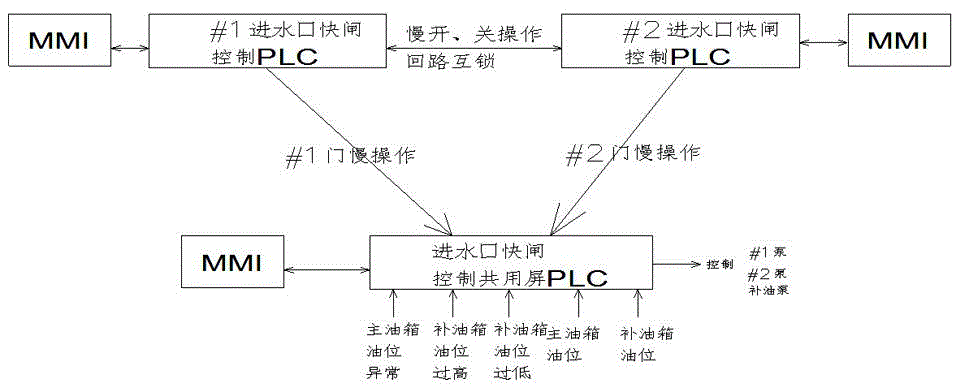

[0011] As shown in Figure 1, this embodiment provides a hydraulic control system for the fast water gate of a hydropower station, which is characterized in that it includes the first water inlet fast gate control panel, the second water inlet fast gate control panel and the common screen; the shared screen for fast gate control of the water inlet completes the automatic and manual start-stop control, pressure building valve control, sound alarm control, oil pressure, oil temperature, filter plugging, main The oil level of the fuel tank and the oil level of the supplementary fuel tank are monitored, and the dual power supply is hot-standby; Operation, fast closing operation; the first and second water inlet fast gate control panels respectively monitor the front and rear water levels, opening degrees, and full-open and full-close stroke limits of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com