Process and system for using waste heat of steam of steam box

A technology of steam waste heat and steam box, which is applied in the direction of heating devices and other non-combustion heat generation. It can solve the problems of inability to recycle steam, deterioration of the environment in the operation room, and easy formation of mist and water droplets, so as to reduce energy consumption and improve recovery. Utilization rate, the effect of realizing centralized recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

[0030] A steam waste heat utilization process of the present invention comprises the following steps,

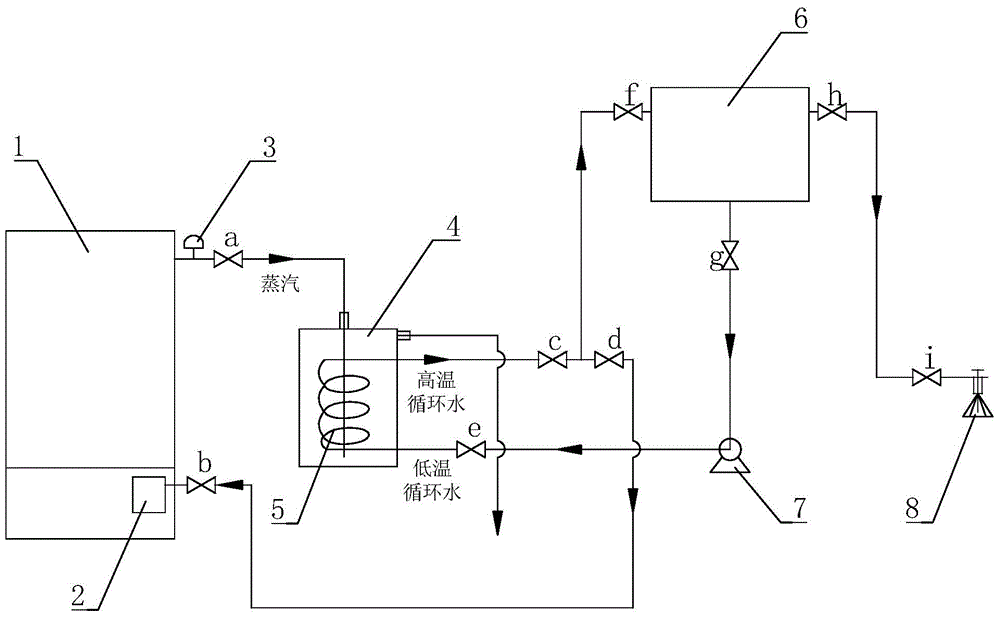

[0031] 1) Steam heat recovery step: import the steam discharged from the steam box 1 into the hot water storage tank 4, and perform a heat exchange with the hot water stored in the hot water storage tank 4, and complete the steam recovery after the hot water storage is heated. Recovery and storage of medium heat; in this preferred example, immersion heat exchange in which steam and normal temperature water are in direct contact is used in the primary heat exchange.

[0032] 2) The transfer step of stored heat: use the heat exchanger 5 in the hot water storage tank 4 to perform secondary heat exchange between the stored hot water and the circulating water in the heat exchanger 5, and the den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com