Multipoint positioning method for wafer macroscopic defect

A multi-point positioning, macro defect technology, applied in the direction of optical testing flaws/defects, measuring devices, instruments, etc., can solve problems such as consumption, inability to find, waste of inspection time, etc., to improve inspection efficiency, save time, and improve inspection speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0027] The invention provides a method for multi-point positioning of wafer macroscopic defects, comprising the following steps:

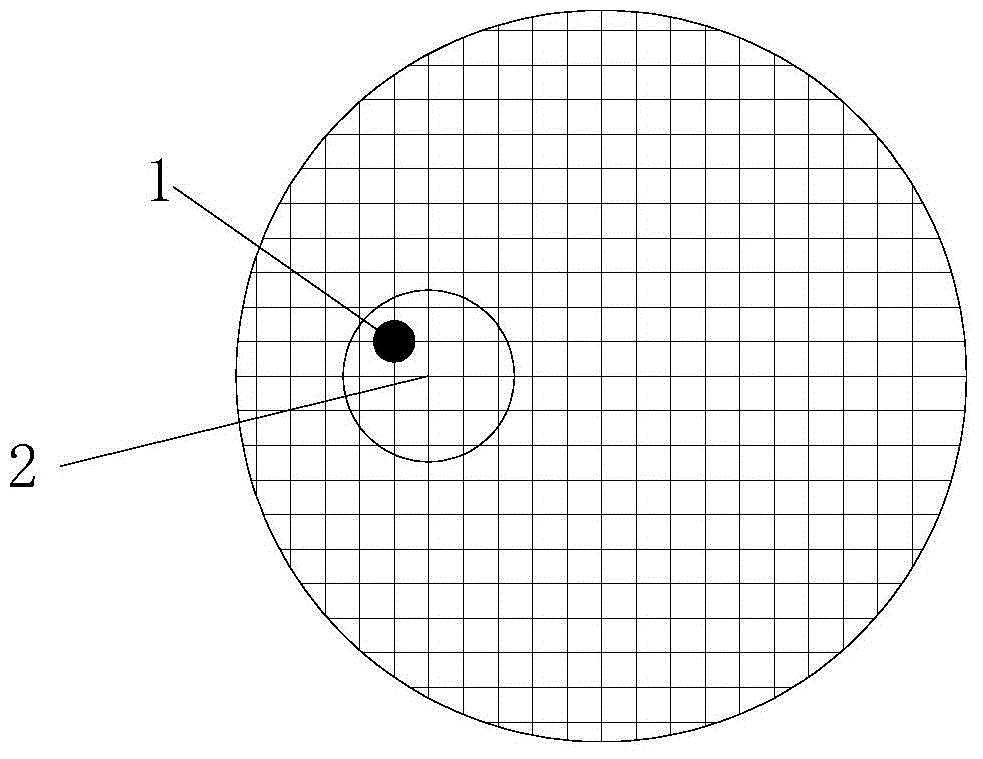

[0028] Provide a wafer that needs to be inspected for defects. First, take a photo of the wafer with macro defects in the macro monitoring area of the Nikon OST3200 microscope. This photo can capture the entire wafer surface. If there are no visible defects in the photo, proceed to other processes; if there are visible defects, then find macro defect 1 on this photo, and perform multiple (more than 10) positioning near this defect, and record the coordinates of each positioning point Then add the horizontal and vertical coordinate values of each positioning point respectively, and then divide them by the number of positioning times to obtain the average coordinate of multiple positioning coordinate values, and calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com