Pressure vessel and method for simulating upper chamber droplet entrainment of nuclear reactor

A technology for pressure vessels and nuclear reactors, applied in the field of experimental devices, can solve the problems of not covering the range of parameters, not covering the pressure range, narrow parameter range, etc., to achieve the effect of improving the safety of experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

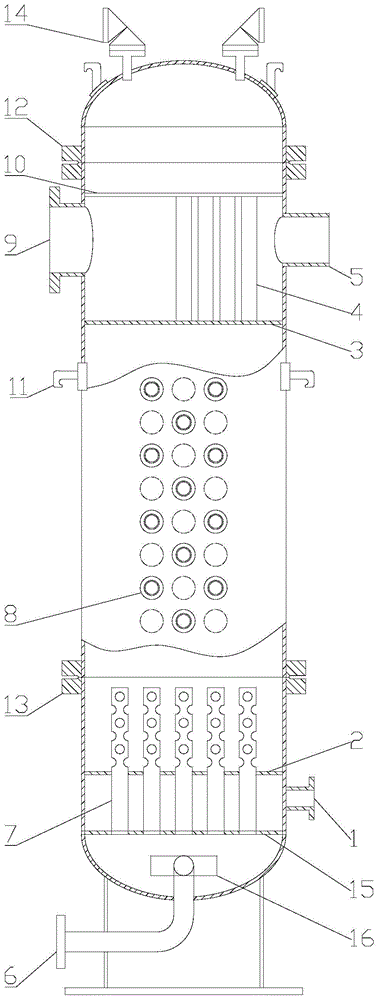

[0037] Embodiment 1: When carrying out the air-water experiment, the air source is provided by the air compressor, and the air enters the interior of the pressure vessel from the air inlet 6 of the lower head of the pressure vessel through the air storage tank and the air filter, and flows out through the outlet heat pipe section 5 Into the steam-water separator, the separated water enters the catch water tank, the lower part of the catch water tank is equipped with a load cell to measure the water entrainment flow, and the air flow is measured by a vortex flowmeter at the gas outlet.

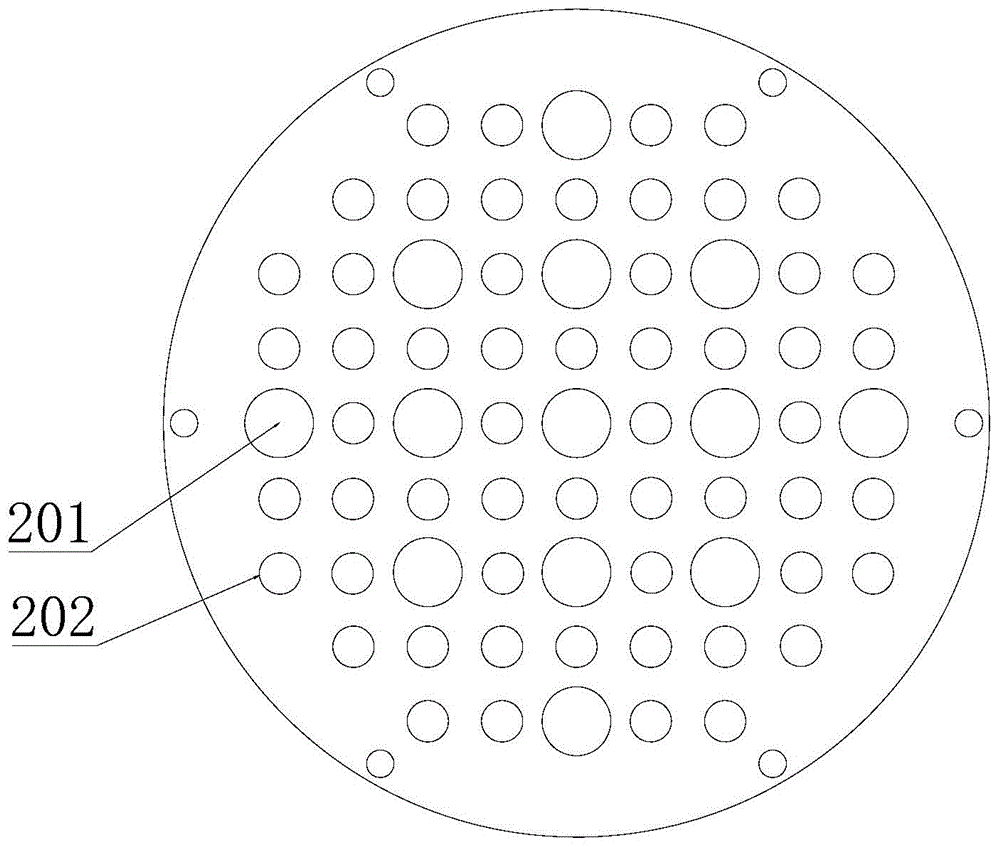

[0038] The water inlet 1 is located at the lower part of the straight pipe section of the pressure vessel. Water enters the pressure vessel from the water inlet 1 and enters the upper chamber through the flow distribution plate 2 and the core upper plate 3 . The numbers of flow holes in the flow distribution plate 2 and the upper core plate 3 are 56 and 24 respectively. The upper chamber is the...

Embodiment 2

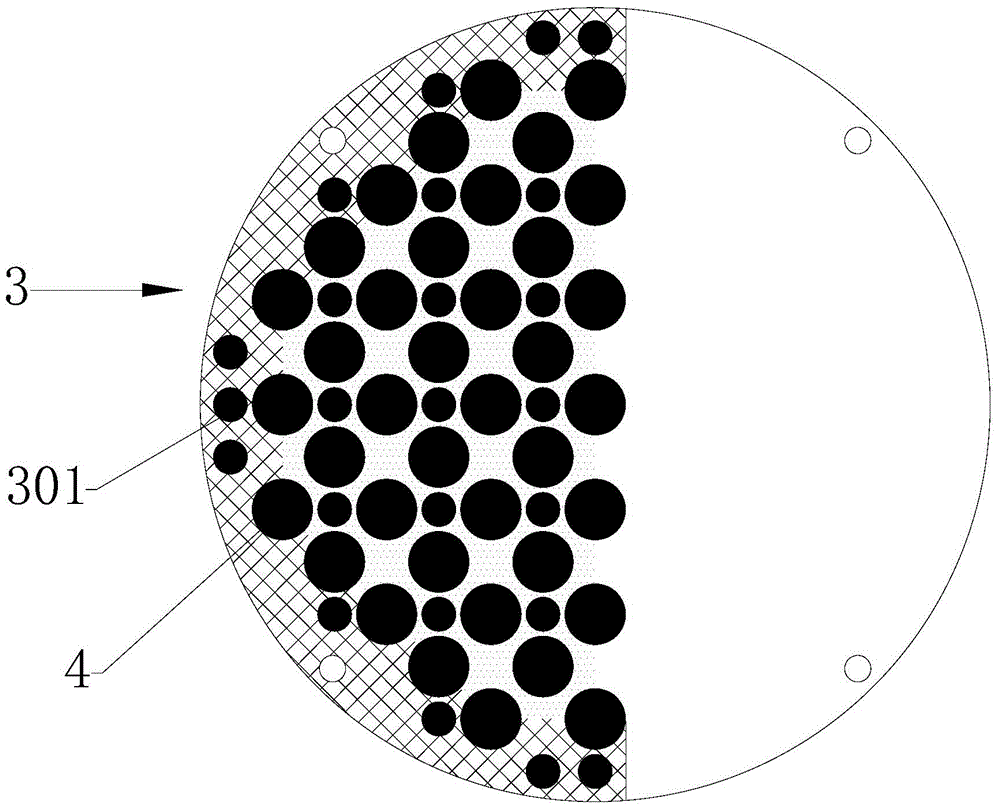

[0040] Embodiment 2: When performing the water vapor-water experiment, in addition to the entrainment mechanism experiment, the entrainment deposition simulation experiment in the upper chamber is also carried out. The reactor internals 4 and the core upper plate 3 need to be installed before the simulation experiment. The circulation holes 301 on the core upper plate 3 can be divided into two types, one is the edge holes, and the liquid droplets entrained by the gas flowing out from such holes directly flow into the horizontal heat pipe section 5 without being deposited by the internal components. ; The other type of hole is the central hole, and the liquid droplets entrained by the gas flowing out of this type of hole must go through at least one layer of deposition of the stack internals 4 tube bundles. The installation of internals 4 will significantly reduce the flow cross-sectional area of the two-phase mixture in the upper chamber, increase the gas-liquid flow rate, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com