Preparation method and application of low-cost liquid polycarbosilane

A polycarbosilane, low-cost technology, applied in the field of preparation of low-cost liquid polycarbosilane, can solve the problems of inability to target products, unfavorable large-scale production, and high requirements for experimental operations, so as to facilitate large-scale production and popularization and application , avoid solvent bumping, improve the effect of reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

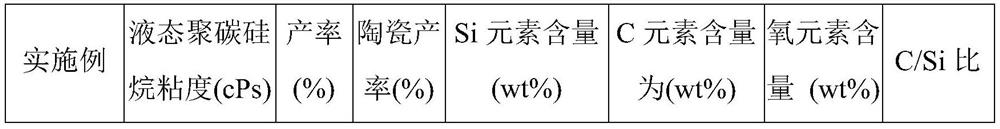

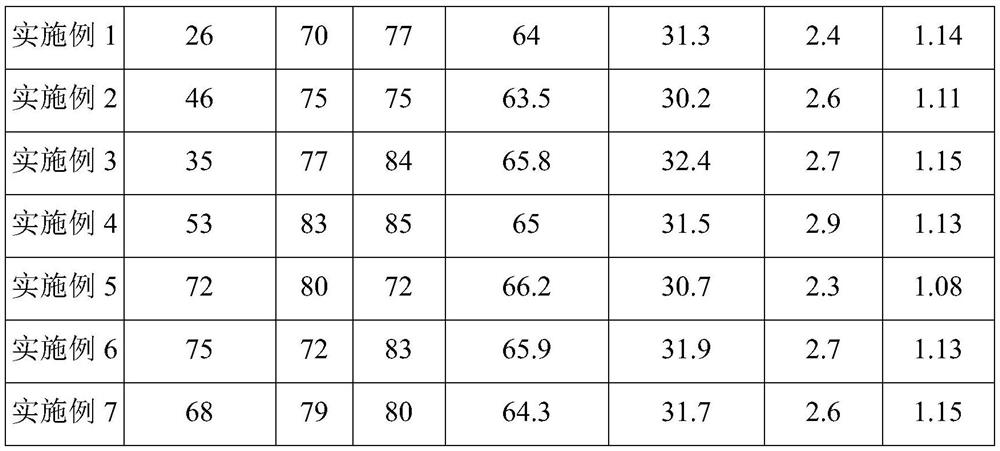

Examples

preparation example Construction

[0026] As mentioned above, the present invention provides a kind of preparation method of low-cost liquid polycarbosilane in the first aspect, it is characterized in that, described method comprises the steps:

[0027] (1) Add the first high-boiling point organic solvent to the magnesium chips, and then add dropwise the first mixed solution comprising halomethylalkoxysilane and the second high-boiling point organic solvent under the condition of heating and stirring. reaction;

[0028] (2) under the condition of heating and stirring, add dropwise the second mixed solution comprising unsaturated halogenated alkanes and the third high-boiling point organic solvent to the first reaction liquid obtained by reacting in step (1) to react;

[0029] (3) adding a reducing agent system to the second reaction solution obtained by the reaction in step (2), and reacting under ultrasonic assistance and stirring;

[0030] (4) adding the reaction solution obtained from the reaction in step (...

Embodiment 1

[0066] Under the protection of nitrogen, add 2 mol of magnesium chips and 4 mol of diethylene glycol dimethyl ether into the reaction kettle equipped with constant pressure dropping funnel, condenser and stirring device in sequence, stir evenly, add 3.2 mol of chloromethyl formazan The first mixed solution of oxydichlorosilane, 16mol chloromethyldimethoxychlorosilane and 0.9mol chloromethyltrimethoxysilane mixture and 2mol diglyme, the temperature is kept at 40 ° C, dropwise After the end, the reaction was continued for 1 hour; then the second mixed solution containing 15 mol vinyl chloride and 4 mol diethylene glycol dimethyl ether was added dropwise, and the temperature was maintained at 60 ° C. After the dropwise addition, the reaction was continued for 1 hour; then 1.4 mol lithium hydride and 0.14mol lithium borohydride, ultrasonic power 100W, stirring rate 100rpm, and maintain the reaction temperature at 50°C for 1 hour; finally, under full stirring, the above reaction sol...

Embodiment 2

[0069] Under the protection of nitrogen, add 2 mol of magnesium chips and 0.2 mol of diethylene glycol dibutyl ether to the reaction kettle equipped with a constant pressure dropping funnel, condenser and stirring device in sequence, stir evenly, dropwise add 0.68 mol of chloromethyl The first mixed solution of ethoxydichlorosilane, 3mol chloromethyldiethoxychlorosilane, 0.27mol chloromethyltriethoxysilane mixture and 0.5mol diethylene glycol dibutyl ether, the temperature is kept at 60°C , continue the reaction for 5 hours after the dropwise addition; then dropwise add the second mixed solution comprising 15mol ethynyl chloride and 0.3mol diethylene glycol dibutyl ether, keep the temperature at 60°C, continue the reaction for 3 hours after the dropwise addition; then Add 1.2mol sodium hydride and 0.08mol lithium borohydride, ultrasonic power 800W, stirring rate 500rpm, maintain the reaction temperature 70°C for 12 hours; finally, under full stirring, add the above reaction sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com