Flexible display module manufacturing method and flexible display module through method

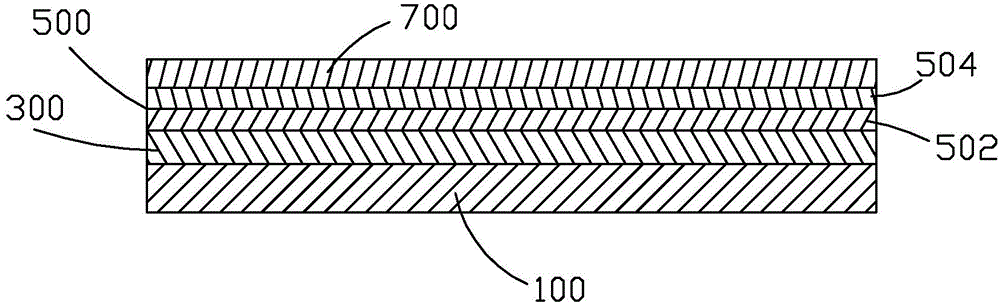

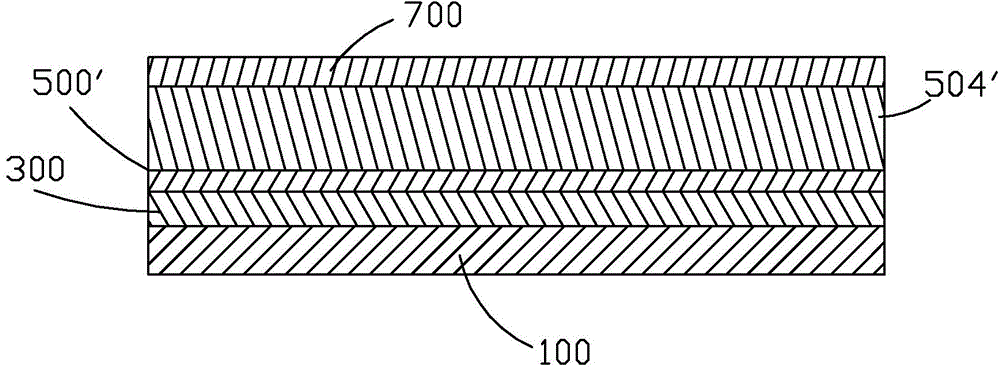

A technology for flexible displays and manufacturing methods, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electric solid-state devices, etc., can solve the problem of poor crystallization of low-temperature polysilicon layer 700, affecting the curling performance of flexible thin-film transistor substrates, and large stress, etc. problems, to achieve the effect of reducing internal stress, avoiding influence, and facilitating thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

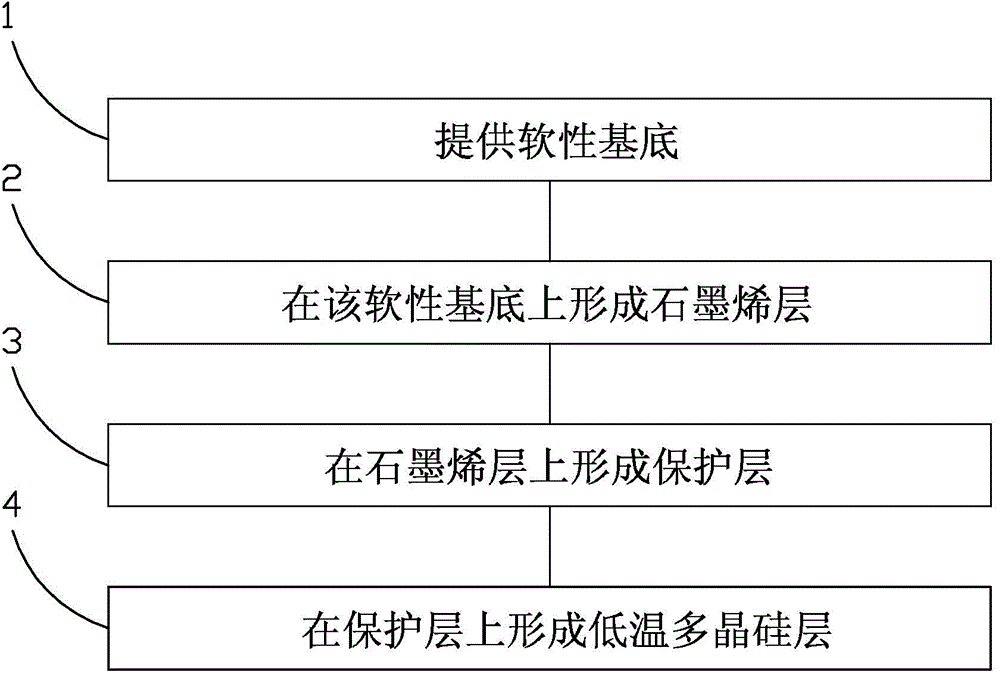

[0031] see image 3 and Figure 4 , the invention provides a method for manufacturing a flexible display assembly, comprising the following steps:

[0032] Step 1, providing a soft base 22 .

[0033] The flexible substrate 22 is made of polyethylene terephthalate (PET), polyethylene naphthalate (PEN), or polyimide (PI). In this embodiment, the flexible base 22 is formed on the glass substrate 20 .

[0034] Step 2, forming a graphene layer 24 on the flexible substrate 22 .

[0035] The graphene layer 24 is formed on the soft substrate 22 by microwave chemical vapor deposition (micro wave CVD), transfer or spin coat process. Graphene is a material with a single-layer sheet structure composed of carbon atoms. Graphene with a three-dimensiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com