Phase compound excitation electric generator

A generator and reactance technology, applied in the direction of synchronous generators, magnetic circuit static parts, magnetic circuit shape/style/structure, etc., can solve the problems of long production process cycle, affecting productivity, large consumption of materials, etc., and achieve weight Lightweight, easy maintenance, and effective use of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

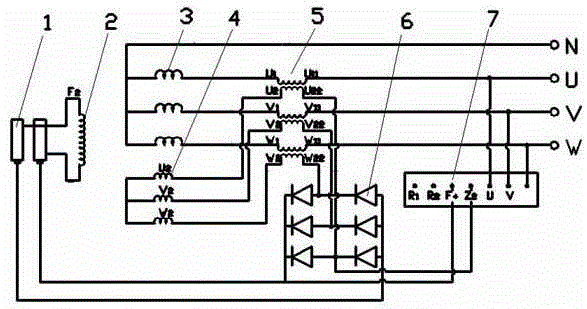

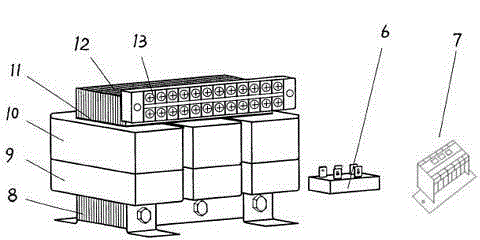

[0034] like figure 1 and figure 2As shown, when the phase compound excitation generator is made into a three-phase synchronous generator, the composite reactance converter is composed of a "mountain" shaped iron core 8, three The three-phase primary winding 9, the three-phase secondary winding 10, the upper yoke core 12 matched with the "mountain"-shaped iron core and the three-phase terminal block 13, the three-phase stator auxiliary winding 4 The phase sequence is the same as that of the three-phase stator main winding 3, and the phase lags behind the stator main winding 3. The three-phase line ends of the stator main winding 3 are connected to the corresponding three-phase ends of the primary winding 9 of the composite structure, and the primary winding 9 The three-phase starting end is the output load end, and the three-phase wire end of the stator secondary winding 4 should be connected with the corresponding three-phase starting end of the secondary winding 10, and the...

Embodiment 2

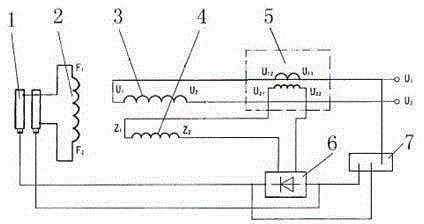

[0043] like image 3 and Figure 4 As shown, when the phase compound excitation generator is made into a single-phase generator, the compound reactance converter is composed of a "U"-shaped iron core 8 installed on the chassis, a single-phase primary Winding 9, single-phase secondary winding 10, upper yoke iron core 12 matched with "U"-shaped iron core 8 and single-phase terminal block 13, the single-phase stator main winding 3 The wire end is connected to the end of the primary winding 9, the beginning of the primary winding 9 is the output load end, the two ends of the single-phase stator secondary winding 4 are connected to the beginning of the secondary winding 10, and the end of the secondary winding 10 is connected to the single-phase rectifier bridge group 6, the other end of the rectifier bridge group 6 is connected to the collector ring 14, and the automatic voltage regulator 7 is connected to the single-phase rectifier bridge group 6, the primary winding 9 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com