Joint treatment device and method for organic waste gas

A technology of organic waste gas and combined treatment, which is applied in combination devices, separation methods, chemical instruments and methods, etc., can solve the problems of affecting the treatment effect, prone to smoldering, and difficult to desorb organic waste gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

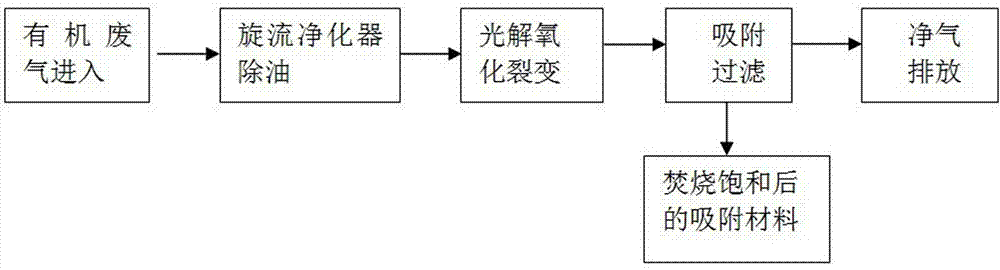

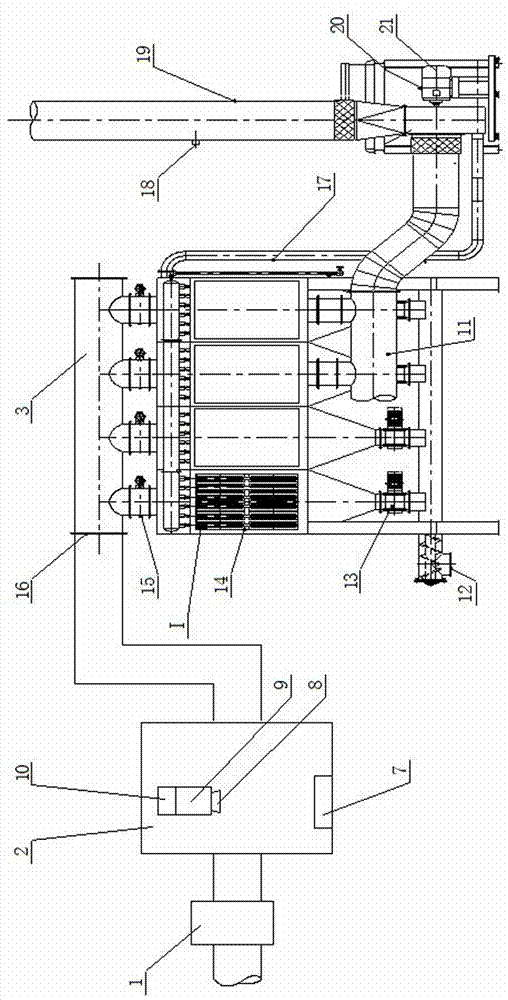

[0035] See figure 1 .

[0036] Combined treatment device for organic waste gas degreasing + photoelectricity + adsorption filtration, including degreasing device 1, photoelectric equipment 2 and adsorption filtration device 3, where degreasing device 1 is installed before photoelectric equipment 2, and adsorption filtration device 3 is installed after photoelectric equipment 2 , the photoelectric device 2 is connected to the adsorption filter device 3 through a pipeline;

[0037] The degreasing device 1 adopts a cyclone purifier.

[0038] A microwave generator 9, a temperature controller 10, an electrodeless lamp 8, a nanophotocatalyst + organic waste gas purification catalyst 7 are installed in the photoelectric equipment 2, and the nanometer photocatalyst + organic waste gas purification catalyst 7 is set at a position where the electrodeless lamp 8 can be irradiated, and the temperature controller 10 is connected to the microwave generator 9, the electrodeless lamp 8 is l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com