A Cleaning Method for Polysulfone Gas Filtration Membrane Contaminated by Dust and Oil

A technology of oil pollution and filter membrane, which is applied in the field of membrane cleaning, can solve the problems of oily substance pollution, air permeability reduction, pollution, etc., achieve good cleaning effect, improve cleaning effect, and remove dust particles and oily stains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

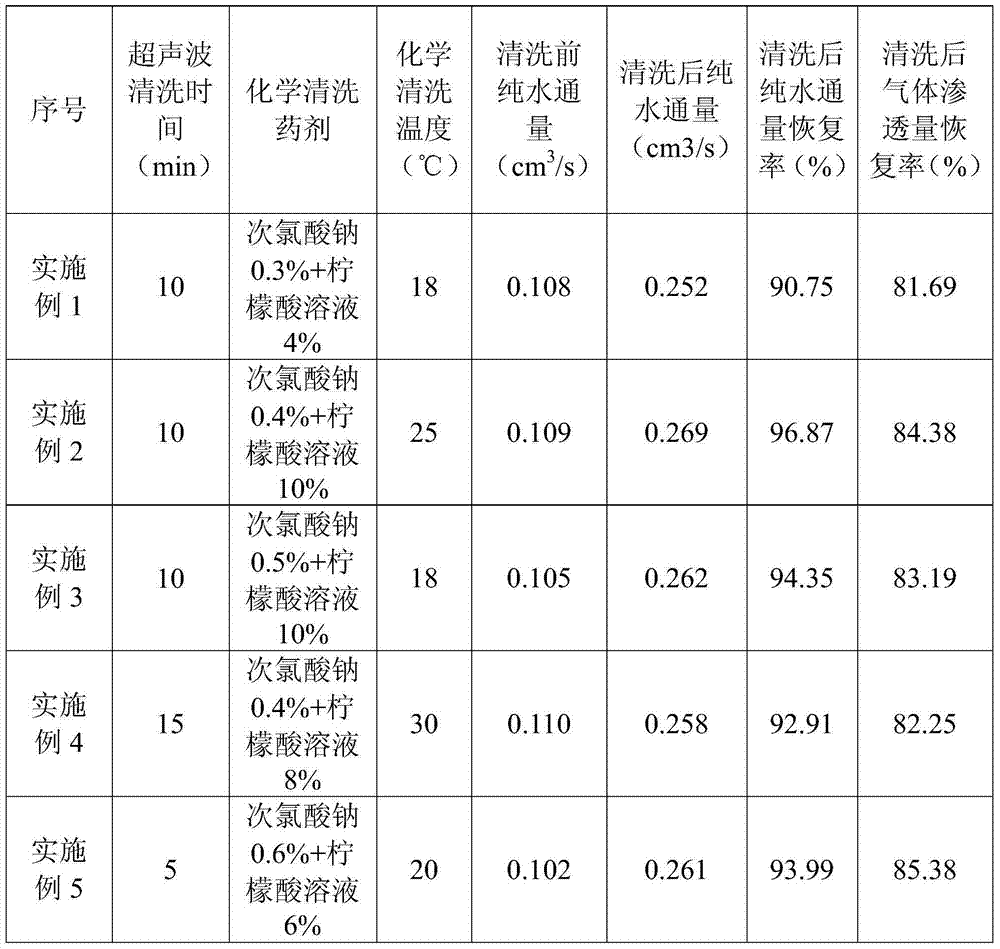

Embodiment 1

[0020] Soak in deionized water at a constant temperature, and soak the polluted membrane in deionized water at a constant temperature of 4°C for 15 hours.

[0021] Preparation cleaning solution, cleaning solution composition weight percent is: sodium hypochlorite 0.3%, citric acid solution 4%, all the other are pure water;

[0022] Ultrasonic cleaning, put the polluted membrane into the ultrasonic cleaning tank, add deionized water, and make the dirt fall off the surface of the membrane through ultrasonic vibration. The ultrasonic cleaning time is 10min, and the ultrasonic frequency is 19KHz~21KHz;

[0023] For chemical cleaning, put the ultrasonically cleaned membrane in the prepared sodium hypochlorite solution, soak for 1 hour at a temperature of 18°C, rinse the membrane soaked in alkali solution, and put it in the prepared citric acid solution for 1 hour. The temperature was 18°C.

Embodiment 2

[0025] Soak in deionized water at a constant temperature, and soak the polluted membrane in deionized water at a constant temperature of 4°C for 15 hours.

[0026] Configure the cleaning solution, the cleaning solution composition weight percentage is: sodium hypochlorite 0.4%, citric acid solution 10%, all the other are pure water;

[0027] Ultrasonic cleaning, put the polluted membrane into the ultrasonic cleaning tank, add deionized water, and make the dirt fall off the surface of the membrane through ultrasonic vibration. The ultrasonic cleaning time is 10min, and the ultrasonic frequency is 19KHz~21KHz;

[0028] For chemical cleaning, first put the ultrasonically cleaned membrane in the prepared sodium hypochlorite solution, soak for 1 hour at a temperature of 25°C, rinse the membrane soaked in alkali solution, and put it in the prepared citric acid solution for 1 hour. The temperature is 25°C.

Embodiment 3

[0030] Soak in deionized water at a constant temperature, and soak the polluted membrane in deionized water at a constant temperature of 4°C for 15 hours.

[0031] Configure the cleaning solution, the cleaning solution composition weight percentage is: sodium hypochlorite 0.5%, citric acid solution 10%, all the other are pure water;

[0032] Ultrasonic cleaning, put the polluted membrane into the ultrasonic cleaning tank, add deionized water, and make the dirt fall off the surface of the membrane through ultrasonic vibration. The ultrasonic cleaning time is 10min, and the ultrasonic frequency is 19KHz~21KHz;

[0033] For chemical cleaning, put the ultrasonically cleaned membrane in the prepared sodium hypochlorite solution, soak for 1 hour at a temperature of 18°C, rinse the membrane soaked in alkali solution, and put it in the prepared citric acid solution for 1 hour. The temperature was 18°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com