Simulation manual feeding method and unit of distillation of Chinese liquor

A kind of manual and liquor technology, which is applied in the direction of transportation, packaging, loading/unloading, etc., can solve the problems of not being able to ensure the uniformity of the retort operation, the lack of taste of distilled wine, and the reduction of manpower operations, so as to reduce labor intensity, improve taste, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

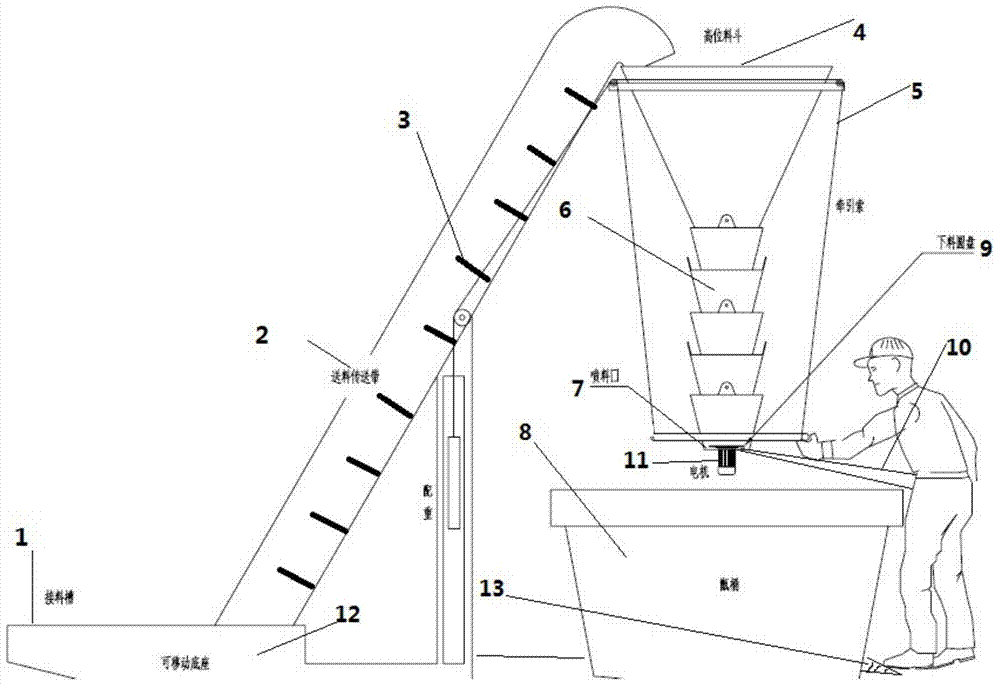

[0015] After the distillation starts, move the movable base 12 to the side of the retort barrel 8, pour the fermented grains material to be distilled into the receiving tank 1, and control the rotation of the feeding conveyor belt 2 through the electric pedal 13, and the material is lifted by the scraper elevator 3 The lower moves to the vicinity of the unloading hopper, and the speed of unloading is controlled by people stepping on the electric pedal, which can realize intermittent control of unloading. The material falls into the high-level hopper 4 under the lift of the scraper elevator 3, and the material falls on the feeding disc 9 along the lowering barrel 6, and the operator moves the lowering barrel 6 back and forth through the traction rope 5 and the operating handle 10 , so that it moves automatically above the retort barrel 8 to realize the blanking operation at different positions. The material falls on the feeding disc 9 through the feeding barrel 6, and the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com