Automatic van-type car rear door hanging and mounting system

A tailgate, fully automatic technology, applied in the directions of transportation and packaging, load hanging components, etc., can solve the problems of quality hazards, ergonomic injuries and high labor intensity of the car body-in-white quality, and achieve easy operation and work. Stable performance and the effect of ensuring occupational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

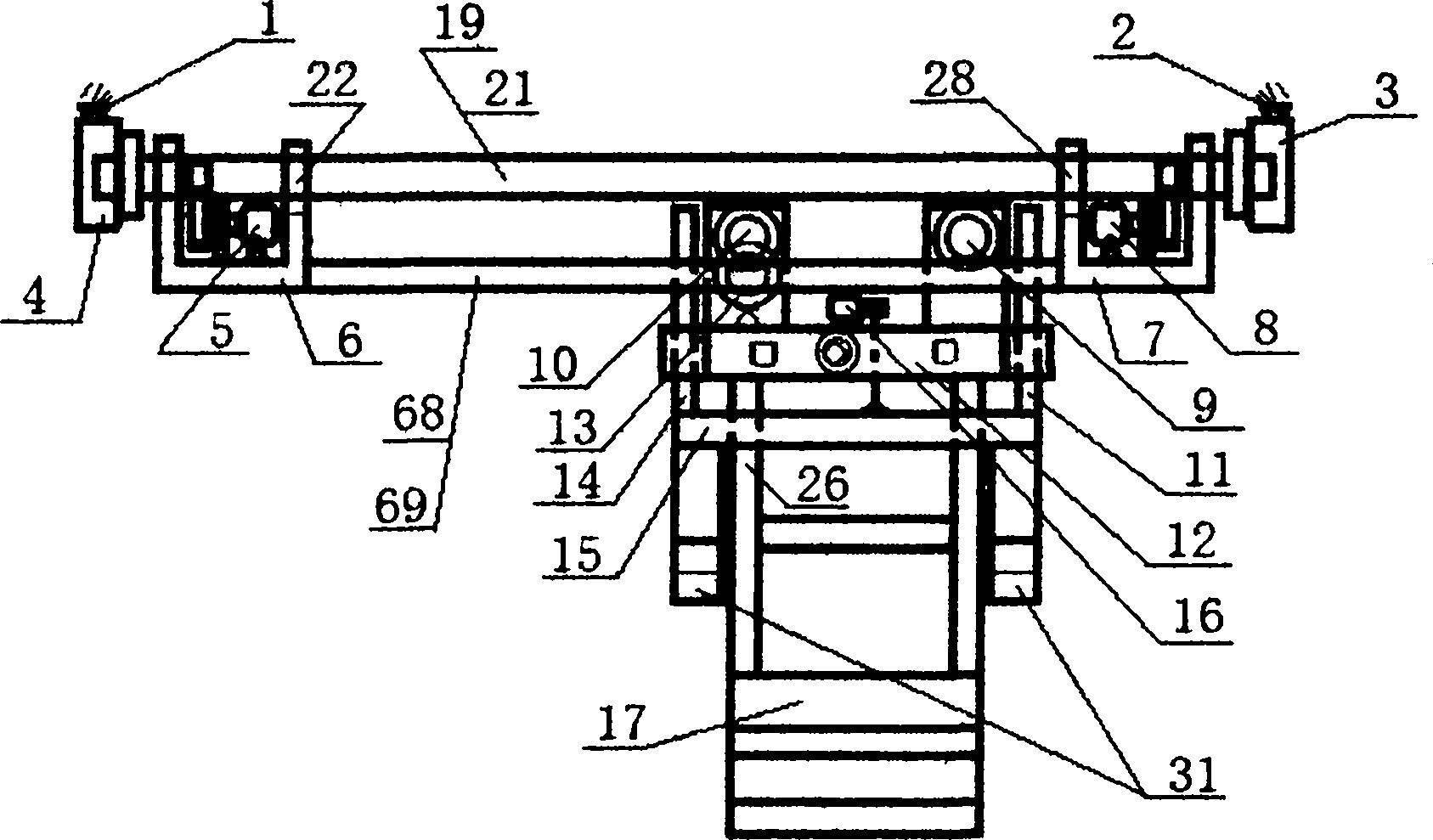

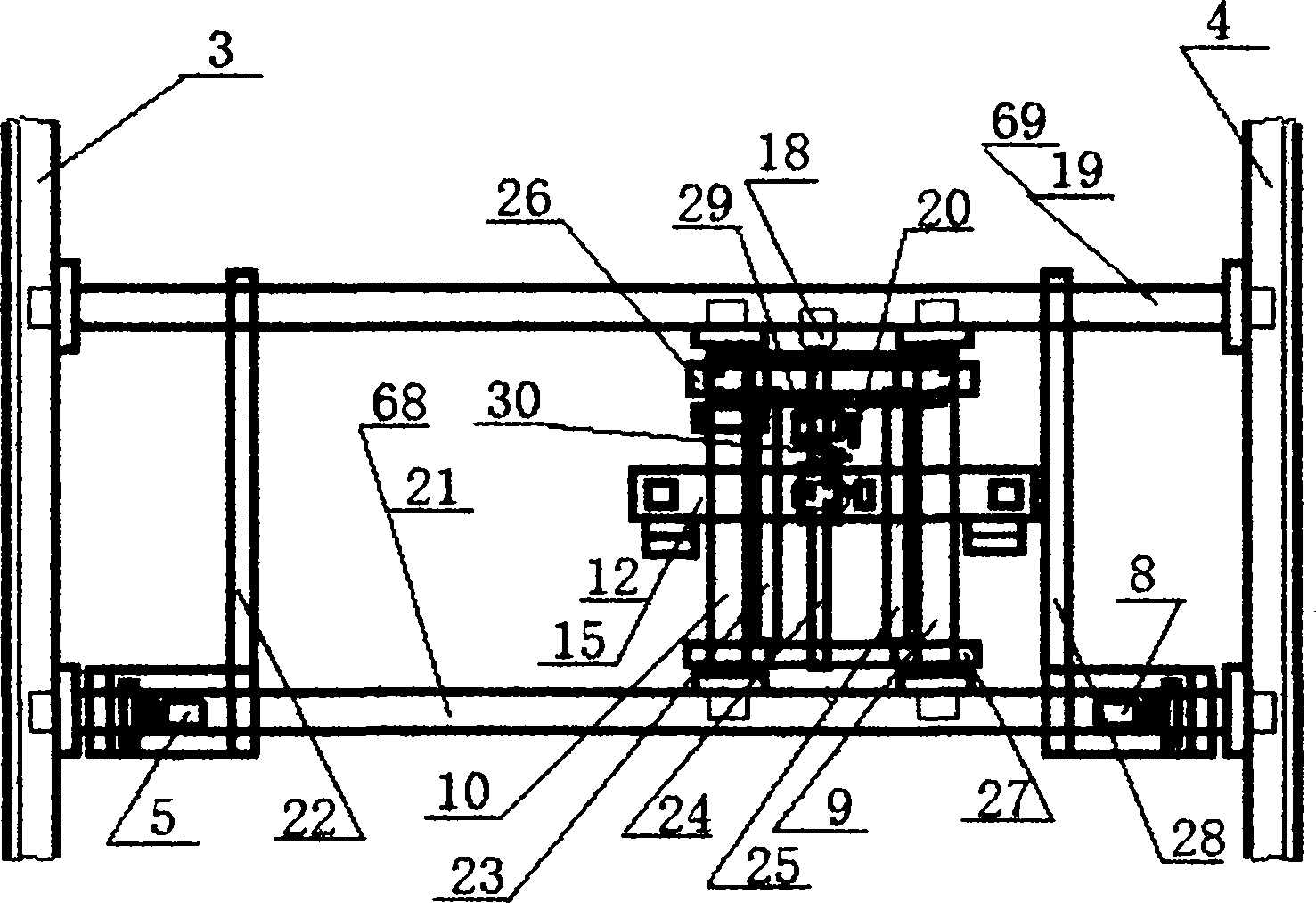

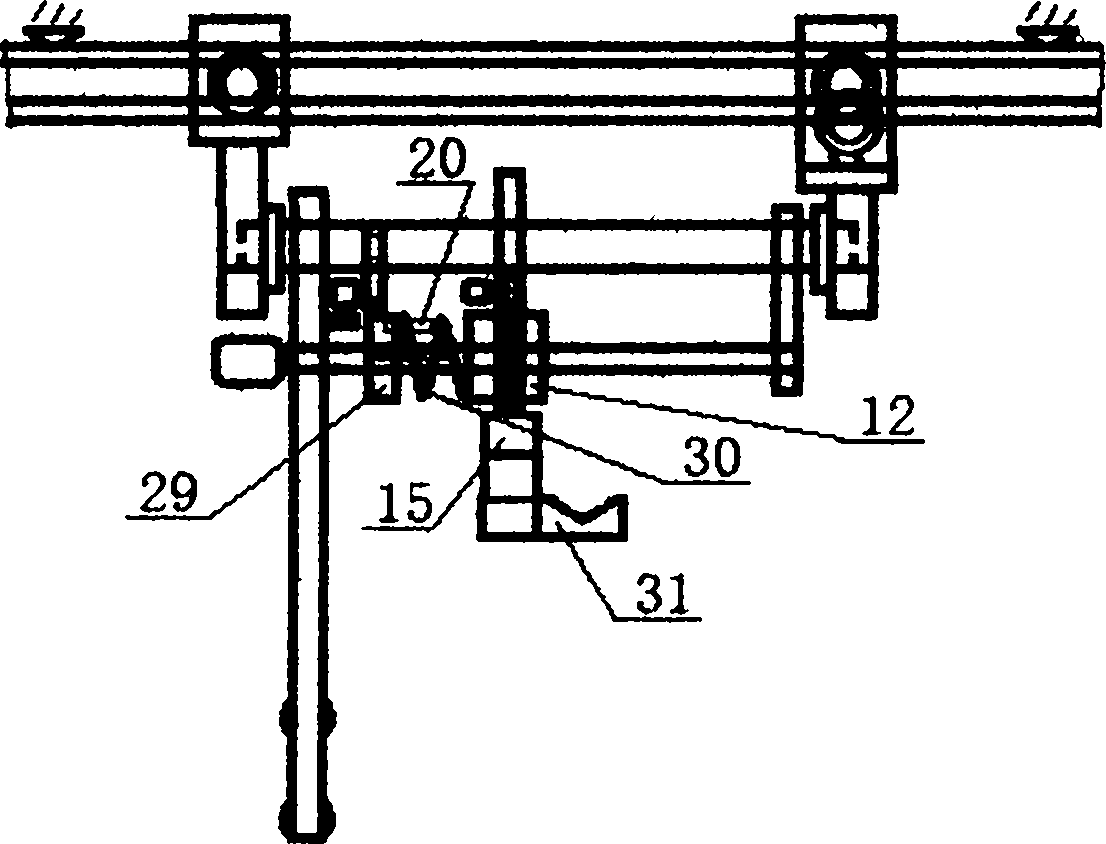

[0024] exist figure 1 Among them, the main stroke guide rail (3) and the main stroke guide rail (4) are firmly connected with the fixed seat (1) and the fixed seat (2), and the main stroke guide rail (3) and the main stroke guide rail (4) are connected with the main balance wheel shaft (19) (21) Rolling connection, the line speed synchronous mechanism motor (5) of the production line is connected with the drive transmission of the main driving wheel shaft (21), the line speed synchronous mechanism motor (5) of the production line is firmly connected with the fixed frame (6) of the line speed synchronous mechanism motor of the production line, The return mechanism motor (8) is connected to the drive transmission of the main driving wheel shaft (21), the return mechanism motor fixing frame (7) is firmly connected to the return mechanism motor (8), and the production line line speed synchronous mechanism motor fixing frame (6) is fixed to the return mechanism motor Frame (7) main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com