Method for making ceramsite from sludge

A sludge and ceramsite technology, applied in applications, clay products, household appliances, etc., can solve the problems of poor control of the moisture of the mixture, low utilization rate of urban solid waste, and easy failure of equipment, so as to protect farmland and reduce energy consumption. The effect of consumption and avoidance of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

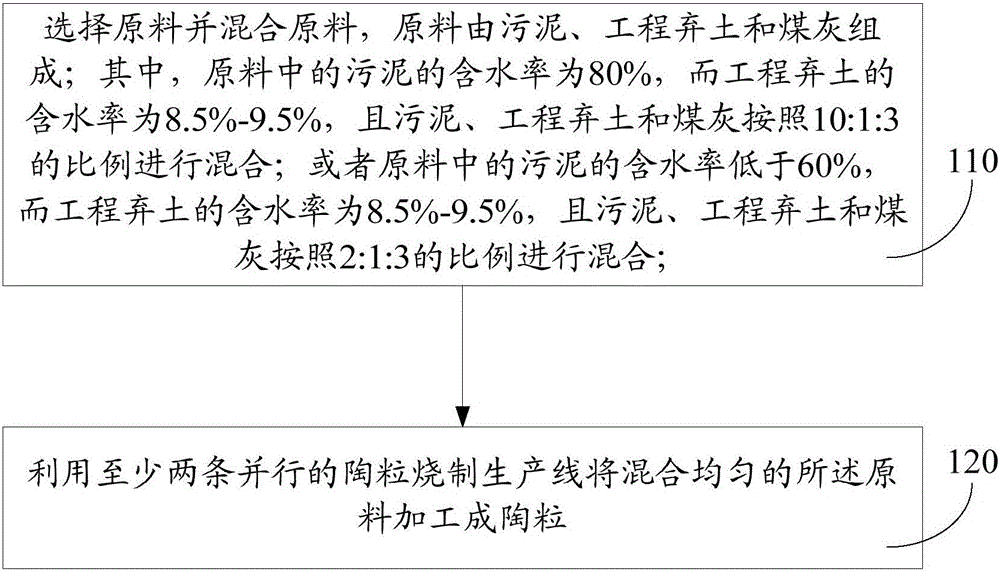

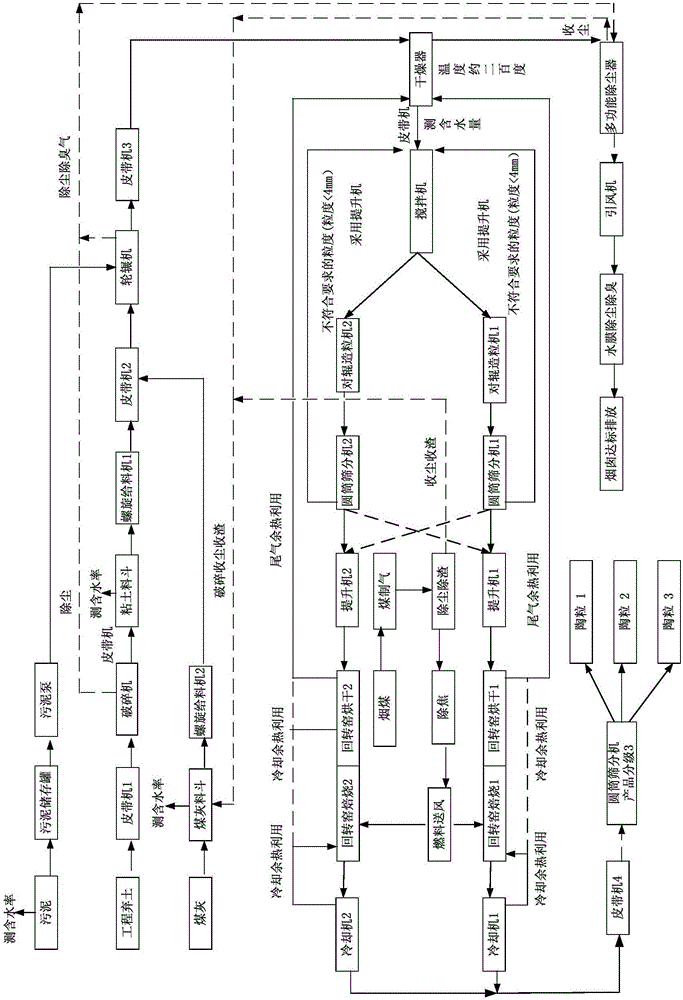

[0022] see Figure 1-2 ,in figure 1 It is a flow chart of the method for utilizing sludge to make ceramsite shown in an embodiment of the present invention; and figure 2 for figure 1 The specific schematic diagram of the method for making ceramsite from sludge is shown.

[0023] Such as Figure 1-2 Shown, the method utilizing sludge of the present invention to make ceramsite comprises:

[0024] Step 110: selecting and mixing raw materials, and the raw materials are composed of sludge, engineering spoils and coal ash;

[0025] When firing ceramsite, the raw materials selected in the present invention are composed of sludge, engineering spoil and coal ash. Among them, the moisture content of the sludge is 80%, while the moisture content of the project spoil is 8.5% to 9.5%. The sludge, project spoil and coal ash in the raw materials are mixed according to the ratio of 10:1:3. The moisture content of the sludge is less than 60%, and the moisture content of the project spoi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com