Cell culture method and cell culture plate applied thereto

A technology of cell culture and culture solution, which is applied in the field of cell culture plates, can solve problems such as inability to accurately predict the results of aerobic cell culture, small gas-liquid phase surface of cell culture plates, and complex structure of small fermentation tanks, and achieve simple structure and high efficiency. Mixing effects, effects that induce violent flipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A cell culture method. The culture device is a cell culture plate. The cell culture plate is fixed on a shaker. Each culture deep hole of the cell culture plate is vertically fixed with a stirring shaft, and a paddle is fixed on the stirring shaft. Under the action of a certain rotation speed and eccentricity provided, the cell culture plate and the paddle move synchronously, and the paddle rotates relative to the culture liquid to stir and mix the culture liquid in the cell culture plate.

Embodiment 2

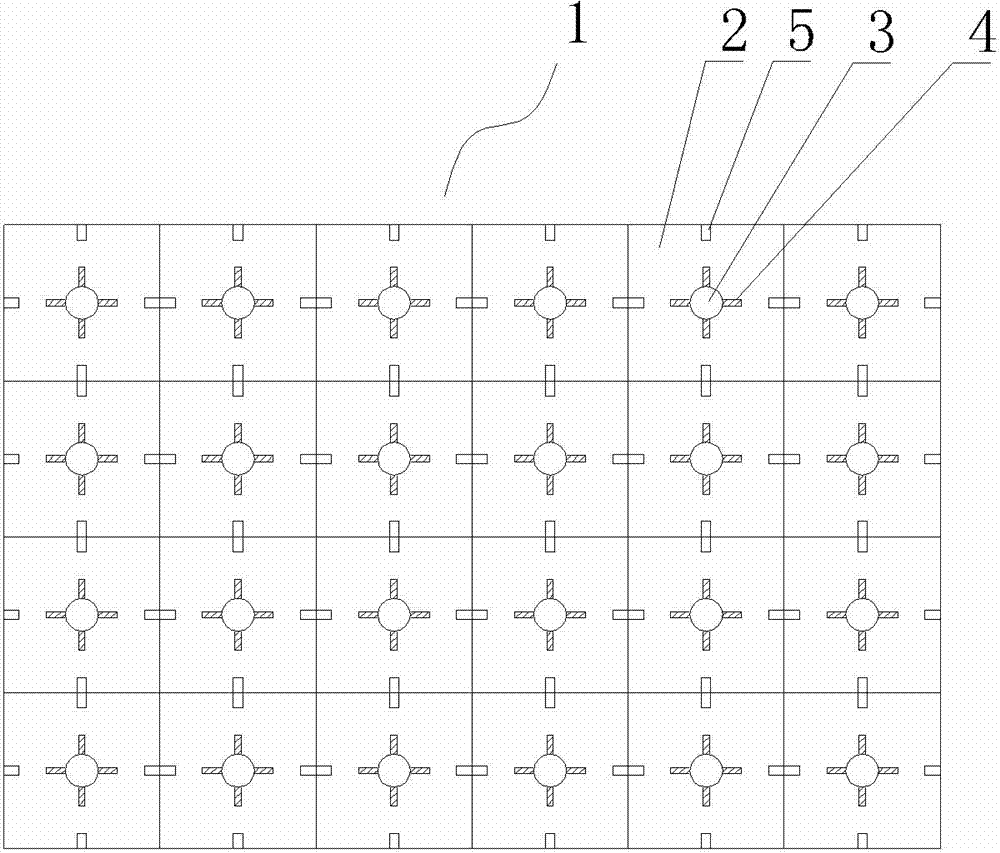

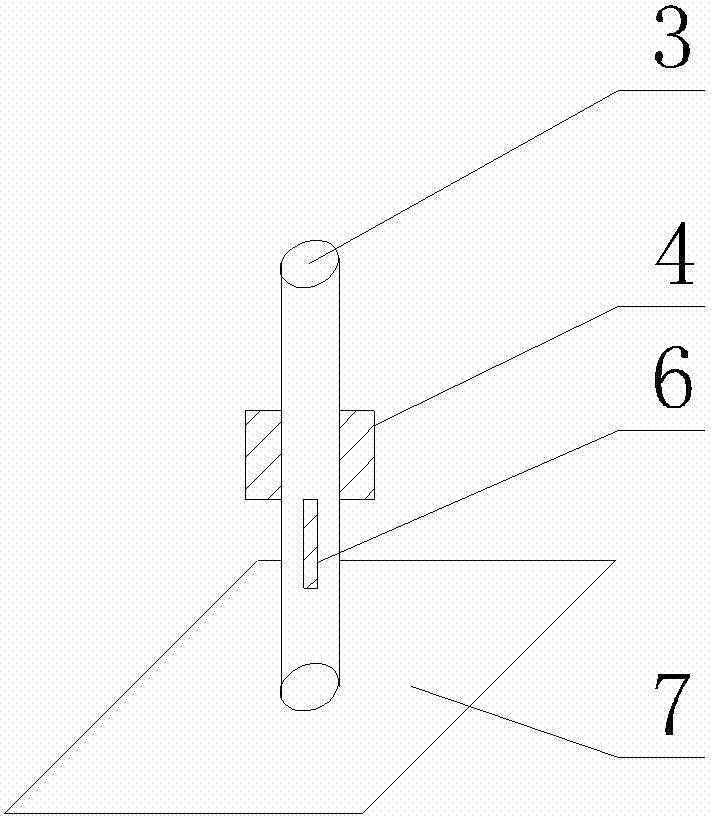

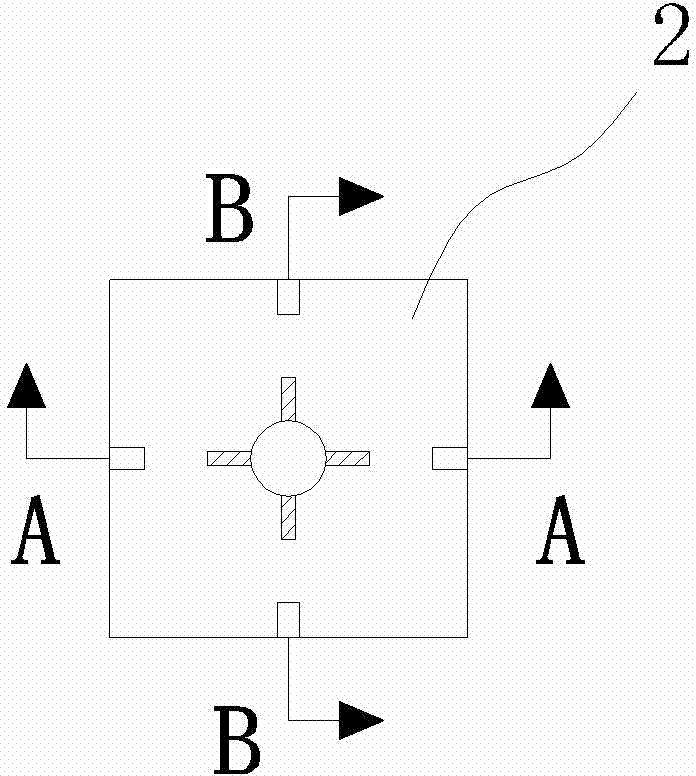

[0027] Such as Figure 1 to Figure 5 As shown, the cell culture plate is evenly distributed with 24 deep culture holes located in the axial direction of the deep culture hole, a stirring shaft is fixed on the bottom end surface of the deep culture hole, and the upper part of the stirring shaft is evenly fixed circumferentially Four paddles, two adjacent paddles are arranged staggered in the depth direction of the deep culture hole, and two opposite paddles are arranged in parallel at the same height in the depth direction of the deep culture hole Four baffles are fixed on the inner periphery of the deep culture hole, and the baffles are evenly distributed along the peripheral surface of the deep culture hole and are arranged at equal height in the depth direction of the deep culture hole.

Embodiment 3

[0029] It is basically the same as Example 2, except that the paddles are arranged at the same height in the depth direction of the deep culture hole.

[0030] Such as Image 6 Said, the cell culture plate is evenly distributed with 24 deep culture holes, located in the axial direction of the deep culture hole, a stirring shaft is fixed on the bottom end of the deep culture hole, and four holes are evenly fixed on the upper part of the stirring shaft in the circumferential direction. Four paddles are arranged at the same height in the depth direction of the deep culture hole; four baffles are fixed on the inner periphery of the deep culture hole, and the baffles are arranged along the circumference of the deep culture hole. The surfaces are evenly distributed and arranged at the same height in the depth direction of the deep culture hole.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com