High-temperature oxidation-resistant steel for non-coating hot stamping

A technology of hot stamping and high temperature oxidation resistance, which is applied in the field of iron and steel materials, can solve the problems of increasing production processes and increasing production costs, and achieve the effects of saving protective atmosphere costs, improving hardenability, and improving oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

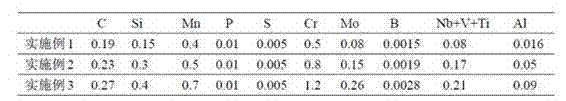

[0023] Embodiments, the technical solutions of the present invention are described below with specific examples, but the present invention is not limited thereto.

[0024] Table 1 shows the chemical composition of a high-temperature oxidation-resistant non-coated hot stamping steel of the present invention; it is vacuum smelted, cast into billets, and rolled to a thickness of 1.8mm after hot rolling and cold rolling.

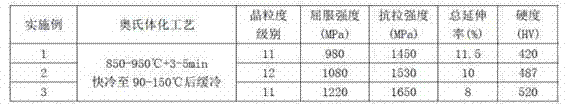

[0025] Table 1 Chemical composition of non-coated hot stamping steels resistant to high temperature oxidation (mass percentage, %)

[0026]

[0027] Cut the cold-rolled and annealed sheet of Example 1 into square sheets of 400×400mm, heat them in a heating furnace to 930°C, and hold the heat for 3 minutes to ensure that they are fully austenitized; Stamping in a flat mold with a cooling system; after stamping and forming, pressurization and quenching are required, the cooling rate is controlled at 40-60°C / s, and the mold temperature is controlled at 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com