Hollow lock panel and method for manufacturing same

A manufacturing method and panel technology, applied in building locks, building structures, buildings, etc., can solve the problems of unfavorable resource conservation and environmental protection, restricting product production efficiency, long production cycle, etc., achieving light weight, material saving, production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

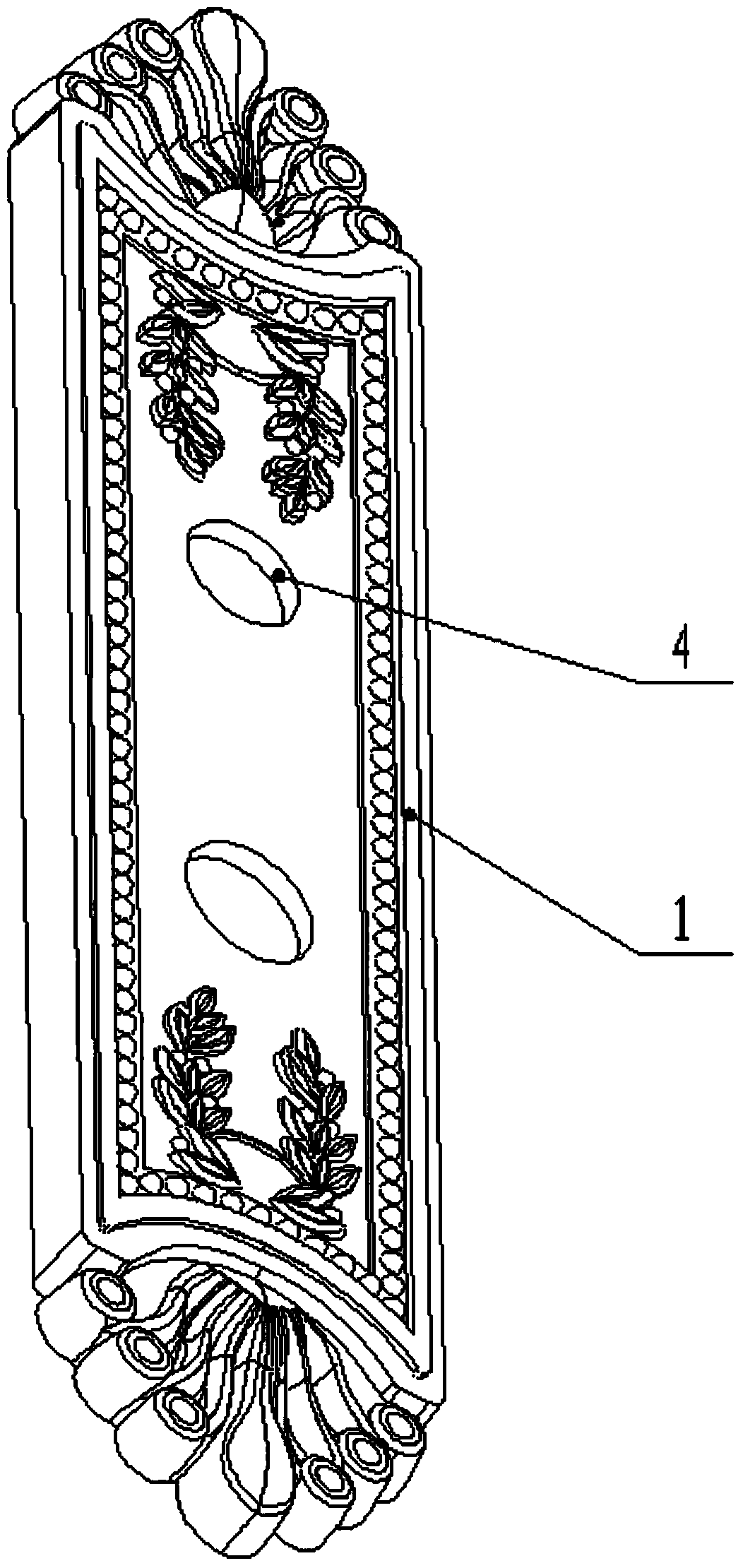

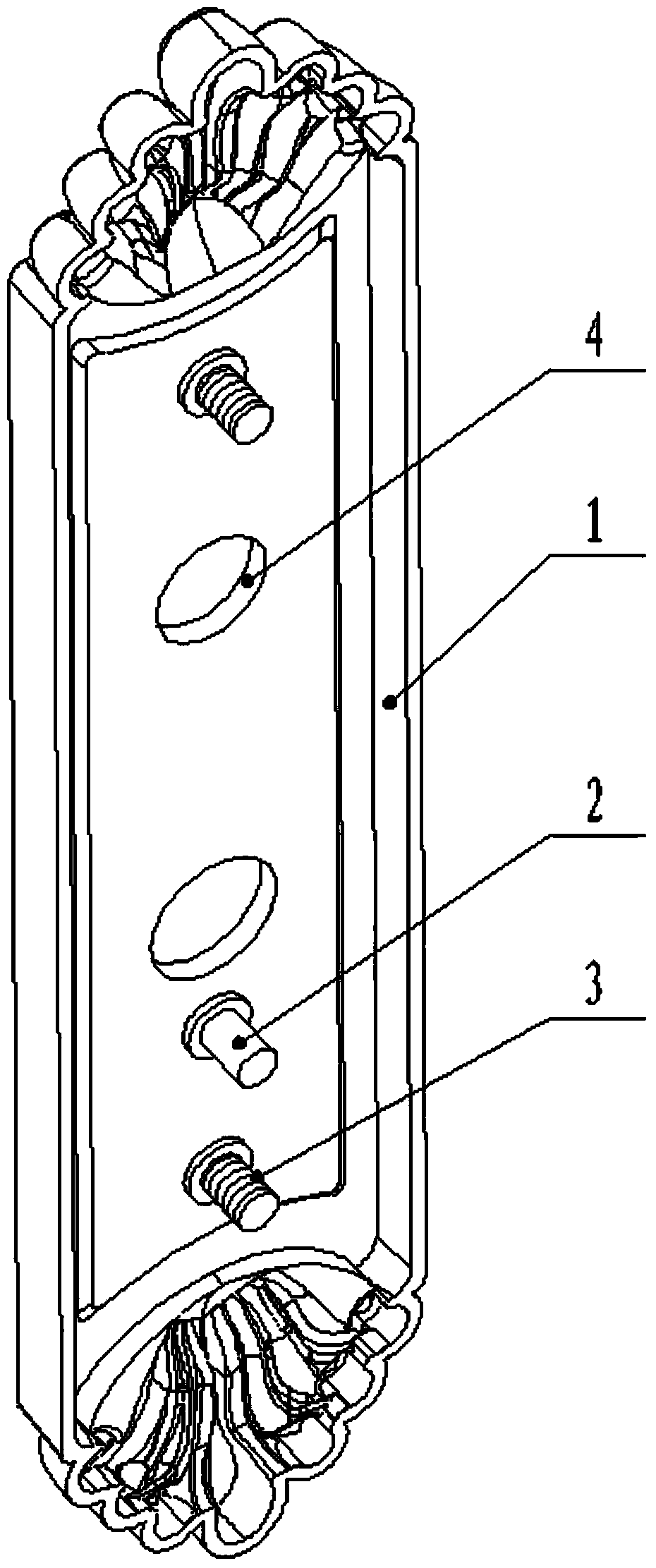

[0028] Such as figure 1 , figure 2 As shown, the manufacturing method of the hollow panel of the lock with a plate thickness of 1mm comprises the following steps:

[0029] (1) Calculating the expanded dimension of the blank of the lock panel shell 1: Calculate the required expanded dimension of the plate blank according to the size of the lock panel shell 1;

[0030] (2) Mold manufacturing: make a stretching mold according to the shape of the lock panel shell 1, and make a cutting mold according to the blank expansion form of the lock panel shell 1;

[0031] (3) Blank blanking: use the cutting die on the punching machine to apply pressure to the metal sheet to cut into the blank of the lock panel shell 1, and the stamping pressure value of the punching machine is 8 tons;

[0032] (4) Stretch forming: Stretch the blank plate with a stretching die on the hydraulic forming machine, and process the blank of the lock panel shell 1 and the hole 4, and the pressure value of the hy...

Embodiment 2

[0038] The manufacturing method of the hollow panel of the lock with a plate thickness of 2mm comprises the following steps:

[0039] (1) Calculating the expanded dimension of the blank of the lock panel shell 1: Calculate the required expanded dimension of the plate blank according to the size of the lock panel shell 1;

[0040] (2) Mold manufacturing: make a stretching mold according to the shape of the lock panel shell 1, and make a cutting mold according to the blank expansion form of the lock panel shell 1;

[0041] (3) Blank blanking: use the cutting die on the punching machine to apply pressure to the metal sheet to cut into the blank of the lock panel shell 1, and the stamping pressure value of the punching machine is 20 tons;

[0042] (4) Stretch forming: Stretch the rough plate with a stretching die on the hydraulic forming machine to process the blank hole 4 of the lock panel shell 1, and the pressure value of the hydraulic forming machine is 120 tons;

[0043] (5)...

Embodiment 3

[0048] The manufacturing method of the hollow panel of the lock with a plate thickness of 3mm comprises the following steps:

[0049] (1) Calculating the expanded dimension of the blank of the lock panel shell 1: Calculate the required expanded dimension of the plate blank according to the size of the lock panel shell 1;

[0050] (2) Mold manufacturing: make a stretching mold according to the shape of the lock panel shell 1, and make a cutting mold according to the blank expansion form of the lock panel shell 1;

[0051] (3) Blank blanking: use the cutting die on the punching machine to apply pressure to the metal sheet to cut into the blank of the lock panel shell 1, and the stamping pressure value of the punching machine is 50 tons;

[0052] (4) Stretch forming: Stretch the blank plate with a stretching die on the hydraulic forming machine to process the blank hole 4 of the lock panel shell 1, and the pressure value of the hydraulic forming machine is 400 tons;

[0053] (5)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com