Combined type optical-electricity encoder with copper code disc

A photoelectric encoder and code disc technology, which is applied in the directions of instruments, converting sensor output, and using optical devices to transmit sensing components, can solve the problems of large system size, limited use range, and poor anti-interference performance, and achieves The production and assembly process is simple, the structure is simple, and the signal output is stable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

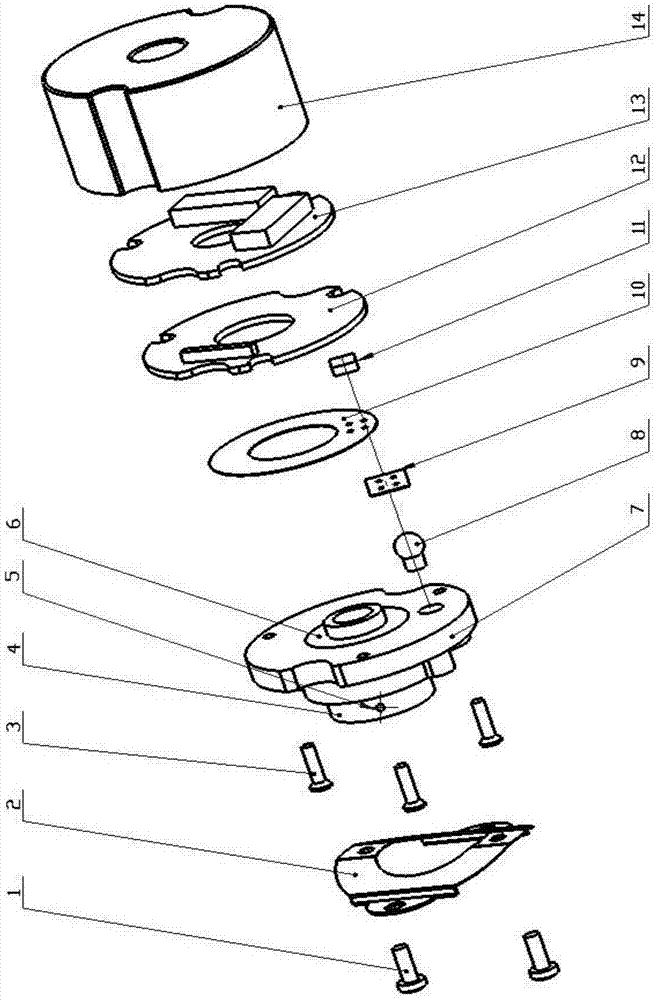

[0015] The following will be attached figure 1 The present invention is described in further detail.

[0016] The present invention includes mounting screw 1, fixed shrapnel card 2, positioning screw 3, connecting shaft sleeve 4, fastening screw 5, bearing 6, base 7, LED light source 8, grating ruler 9, copper code disc 10, photoelectric A receiving component 11, a signal conditioning circuit board 12, a signal amplifying circuit board 13, a casing 14, and the like. The shaft sleeve 4 and the fastening screw 5 are used together to tightly connect the motor shaft and the encoder, wherein the shaft sleeve 4 is connected to the base through the bearing 6 and the end of the shaft sleeve 4 far away from the motor shaft is tightly connected to the copper code disc 10 . The fixed shrapnel card 2 tightly connects the base 7 and the rear flange of the motor to prevent the radial displacement of the encoder. The grating ruler 9 is fixedly installed between the LED light source 8 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com