Method for automatically recognizing element spectral line in LIBS component analysis

A technology of automatic identification and composition analysis, applied in material excitation analysis, spectrum investigation, etc., can solve problems such as loss of spectral data, spectral data, errors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

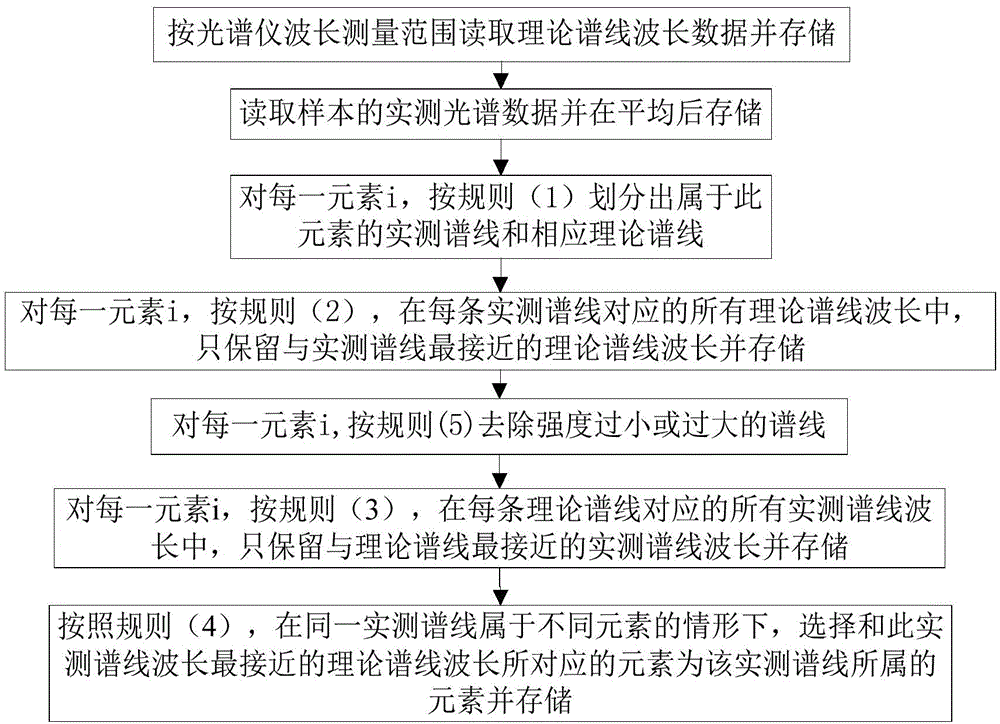

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

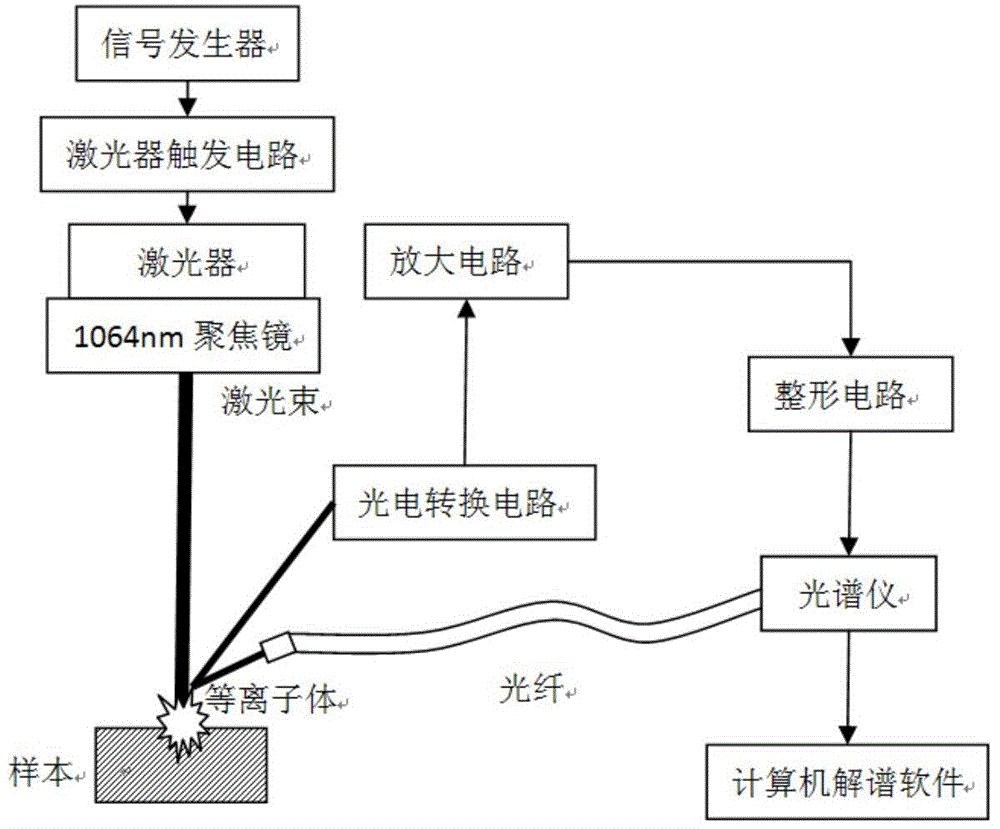

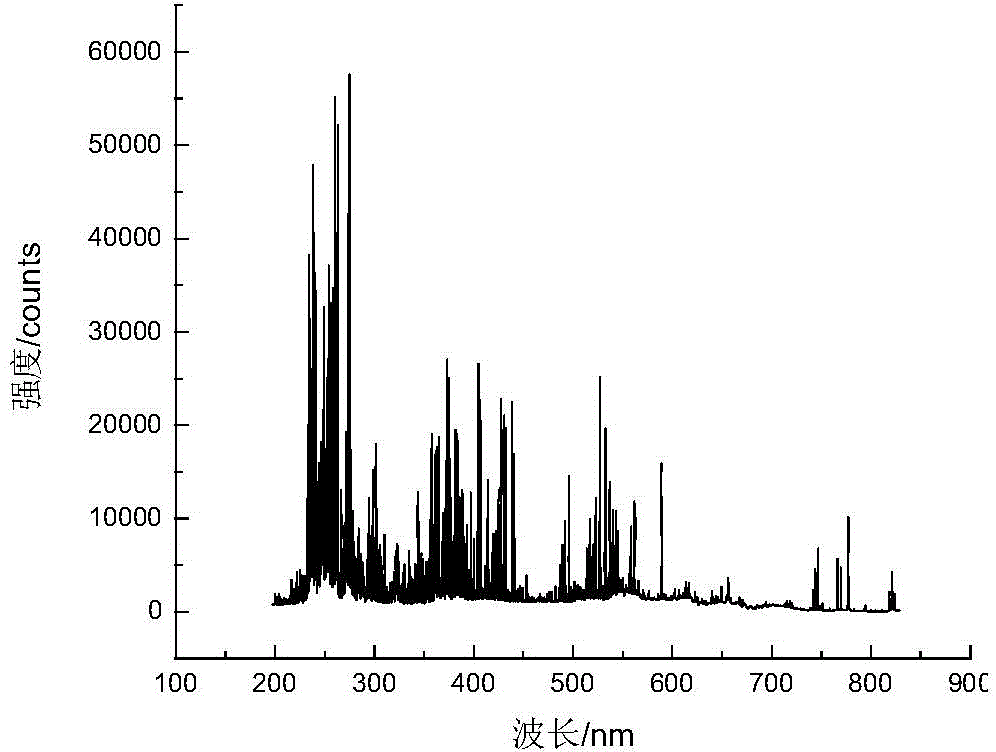

[0070] 1 Experimental device and steps

[0071] LIBS experimental system such as figure 1Shown (Wu Shaobo, Ye Lianhui, Sun Yanguang, et al. Feasibility study of domestic Nd:Yag beauty laser for LIBS component analysis [J]. Instrumentation Journal, 2013, 34(6):181-186). Use MK-101Nd:Yag pulse laser, laser wave 1024nm, energy 106mJ, pulse width 14.2ns. Using Avaspace-2048-4-USB2 spectrometer, the wavelength range is 200nm to 850nm, and the measured spectral wavelength interval is 0.02-0.13nm. The signal generator adopts DG535 pulse delay generator, which can trigger the laser to repeatedly emit laser pulses at a specified frequency through the laser trigger circuit. The low alloy steel standard sample N-LA17GBW 01211 was used in the experiment, and its sample composition is shown in Table 1. The computer used is a virtual machine in the unit's cloud computing platform: Windows Server2003 operating system, 3.75G memory, 8-core CPU 1800MHz / core.

[0072] Table 1: Composition (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com