Gas chemical solvent absorption and desorption reaction heat measuring device and measuring method

A chemical solvent, measuring device technology, applied in the direction of measuring devices, scientific instruments, material thermal development, etc., can solve the problems of heat measurement error, error, heat conduction loss, etc., to achieve the effect of easy calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

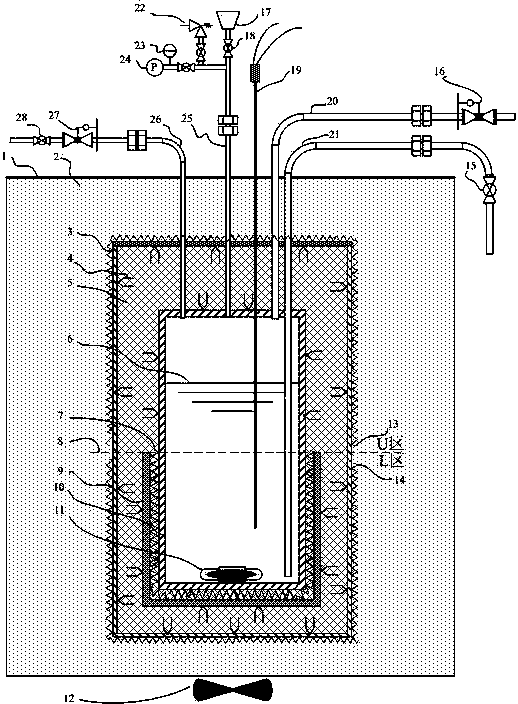

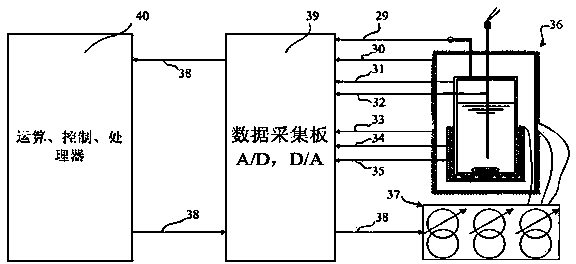

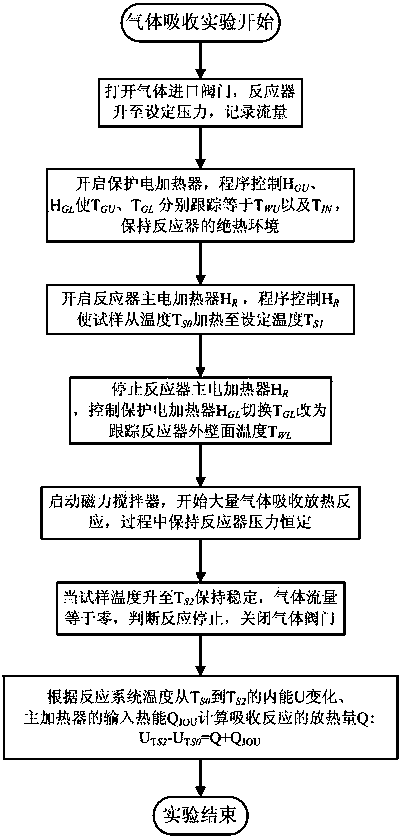

[0024] see figure 1 and figure 2 Shown: the reaction calorimeter of the present invention, which is composed of: the metal inner shell (3) and the outer shell (1) are filled with heat insulating material (2) in the middle. The dotted line separating the regions (8) will figure 1 It is divided into two areas, U and L, representing the upper and lower areas respectively. The electric heater H is distributed in the outer U area of the inner shell (3) GU (13), the electric heater H is distributed in the outer L area GL (14), multiple sets of temperature measuring thermocouples (4) are evenly distributed on the inner side, and the average temperatures of the measured U and L regions are T GU (30) and T GL (33). The gap between the inner shell (3) and the reactor (10) is filled with glass fiber insulation material (5), and the main electric heater H is distributed in the area L outside the reactor (10) R (7), and its outer side is covered with a certain thickness of glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com