Wet etching method in silicon solar cell production

A silicon solar cell, wet etching technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of the edge of the silicon wafer cannot be adsorbed, the chemical liquid cannot be carved, and achieve the effect of improving the conversion efficiency and increasing the effective area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

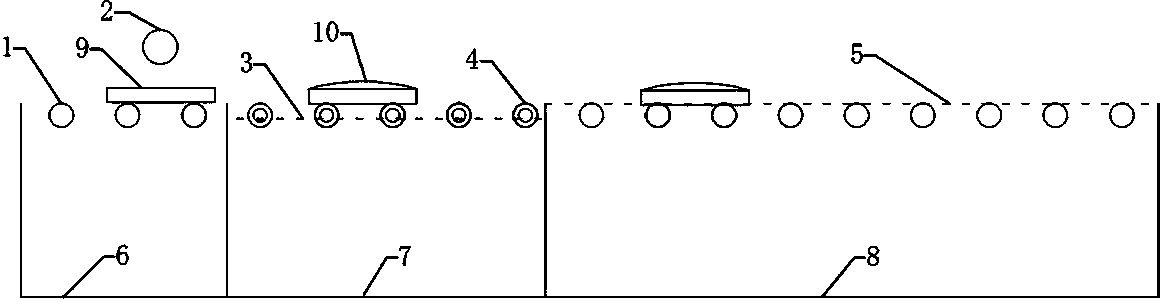

[0015] as attached figure 1 As shown, a wet etching method in the production of a silicon solar cell includes a water film protection step and an etching step, and a phosphorous silicon glass removal step is added between the water film protection step and the etching step. The specific steps are as follows:

[0016] (1) Water film protection step: place the silicon wafer 9 on the roller 1 in the water tank 6, and then spray deionized water on the diffusion surface of the silicon wafer 9 through the water spray system 2 to form a water film protection layer 10. The water film protection layer 10 continues to exist until the silicon wafer 9 completes the etching step;

[0017] (2) Phosphorous silicon glass removal step: After the water film protection step, the silicon wafer 9 enters the hydrofluoric acid tank 7, and the hydrofluoric acid tank 7 is equipped with a hydrofluoric acid solution 3 with a concentration of 10%, and a hydrofluoric acid solution 3 The height is lower t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com