High-power high-frequency power supply system for high-potential electronic circuit and method of high-power high-frequency power supply system

A high-frequency power supply and electronic circuit technology, applied in the field of electronics, can solve problems such as difficulty in applying to 35kV voltage and above, poor overall performance consistency of the power supply system, unfavorable product modularization and standardization, etc., to optimize energy transmission efficiency, reduce Dispersion, low harmonic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

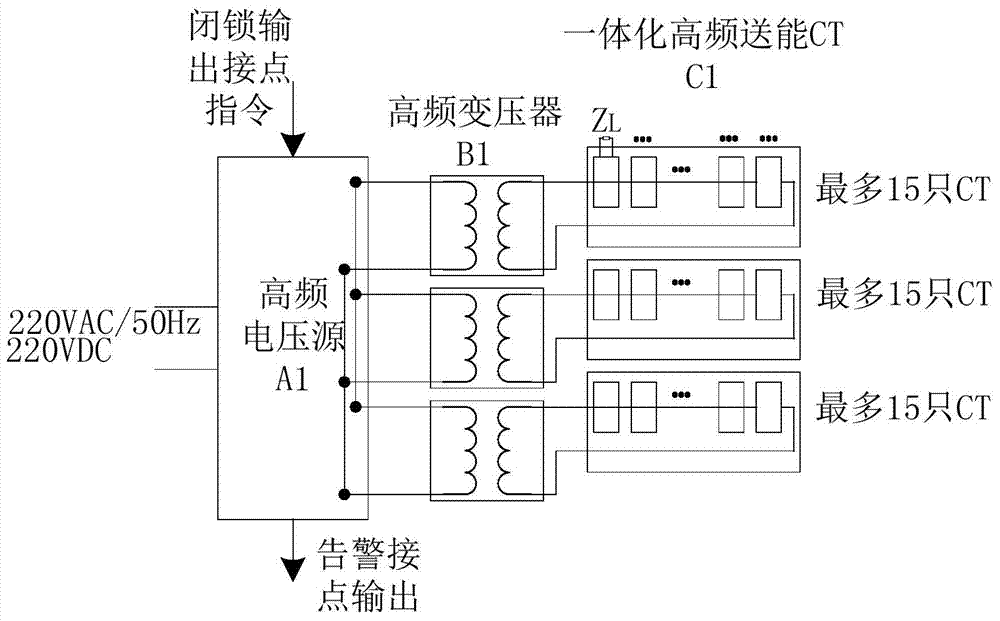

Embodiment 1

[0053] Such as figure 1 As shown, this embodiment includes: one high-frequency voltage source A1, three high-frequency transformers B1 and three-column casting integrated high-frequency energy-transmitting CT C1. Among them: the input end of the high-frequency voltage source A1 is connected to low-voltage DC voltage or AC mains, and the input voltage is converted into a high-frequency signal, which is output to three high-frequency transformers B1; the primary sides of the three high-frequency transformers B1 are connected in parallel, Connect to the output of the high-frequency power supply, and each of the secondary sides is connected to a cast-type integrated high-frequency energy-transmitting CT C1; the high-frequency energy-transmitting CT is connected in series by the primary sides of up to fifteen high-frequency CT monomers and then connected to a high-frequency transformer The secondary side is connected to the valve body at a single point equipotentially, and the seco...

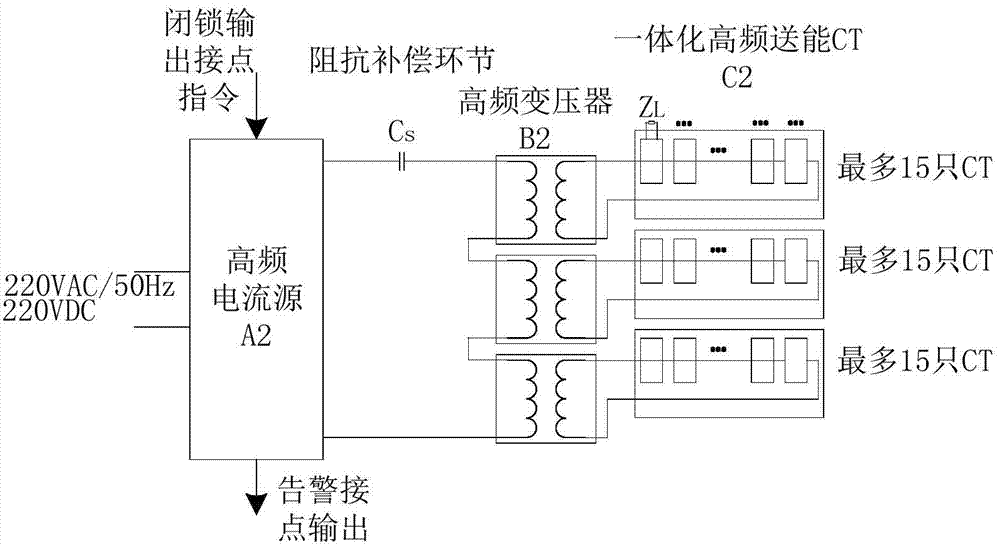

Embodiment 2

[0058] Such as figure 2 As shown, this embodiment includes: one high-frequency current source A2, three high-frequency transformers B2, three-column casting integrated high-frequency energy-transmitting CT C2 and impedance compensation link Cs. Among them: the input end of the high-frequency current source A2 is connected to a low-voltage DC voltage or AC mains, and the input voltage is converted into a high-frequency signal. After the primary sides of the three high-frequency transformers B2 are connected in series, one end is connected to the impedance compensation link Cs, One end is connected to an output end of the high-frequency current source A2; the other end of the impedance compensation link Cs is connected to the other output end of the high-frequency voltage source A2. The secondary sides of the three high-frequency transformers B2 are each connected to a cast-type integrated high-frequency energy-transmitting CT C1; the high-frequency energy-transmitting CT is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com