Solar cell piece PID (potential induced degradation) test device and test method

A technology for solar cells and testing devices, which is applied in the monitoring of photovoltaic power generation, electrical components, photovoltaic systems, etc., can solve the problems of long test cycle, complex process, and the inability to timely feedback the quality of battery production process anti-PID, and achieve The effect of saving test time, saving inspection cost and optimizing production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

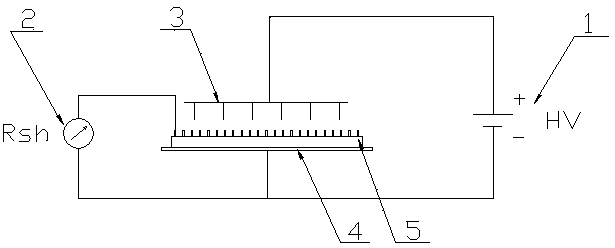

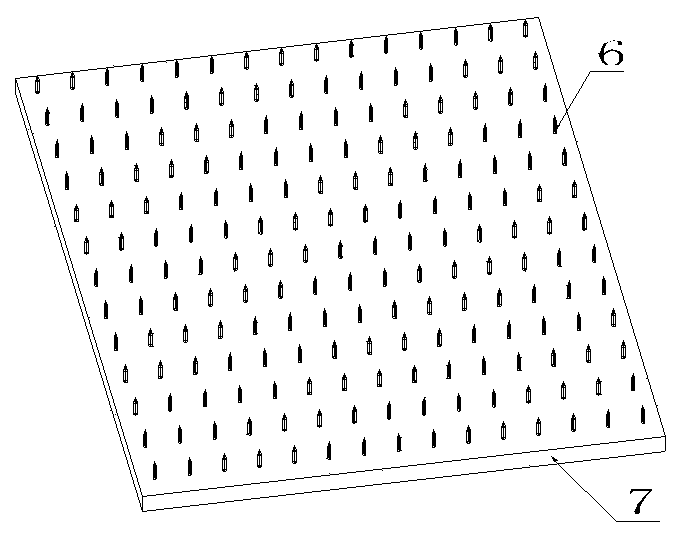

[0025] Embodiment 1: as figure 1 Shown is a solar cell PID test device, which is used for testing 5-inch and 6-inch solar cells, including a DC voltage device 1, a resistance tester 2, a metal electrode row 3 and a metal tray 4, and the metal electrode row 3 and the The positive pole of the DC voltage generator 1 is connected, the metal tray 4 is connected with the negative pole of the DC voltage generator 1, one of the test lines of the resistance tester 2 is connected with the metal tray 4, and the other test line is used to connect the electrodes of the solar battery sheet 5 . The metal electrode row 3 is composed of 225 metal electrodes 6 welded on a metal plate 7 of 160mm×160mm, such as figure 2 . The distance between the metal electrode row 3 and the metal tray 4 can be adjusted so that when the solar cell 5 is placed on the metal tray 4 during testing, the distance between the metal electrode row 3 and the electrodes of the solar cell 5 is 0.1-10 cm. The DC voltage ...

Embodiment 2

[0026] Embodiment 2: A solar cell PID test method, using the solar cell PID test device provided in Example 1, the specific test steps are as follows:

[0027] (1) Place the solar cells 5 on the metal tray 4, and control the distance between the metal electrodes 6 of the metal electrode row 3 and the electrodes of the solar cells 5 to be 2 cm. Connect the test line of the resistance tester 2, control the ambient temperature to 25°C, and the relative humidity to 80%;

[0028] (2) Turn on the DC voltage device 1, and cause the metal electrode row 3 to generate corona discharge under the action of a high voltage of 20KV, and the ion flow acts on the surface of the solar cell 5;

[0029] (3) Continuously irradiate the solar cells 5 with ions for 6 hours, and take samples once / 20 minutes (test every 20 minutes) to test the changes in the parallel resistance of the solar cells 5 in real time;

[0030] ⑷ Make a graph to record the change of parallel resistance.

[0031] Analyze the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com