Antibacterial synthetic fiber, and method for manufacturing same

A synthetic fiber and fiber technology, which is applied in the manufacture of rayon, chemical characteristics of fibers, medical preparations containing active ingredients, etc. Antibacterial activity, effect of long-lasting antibacterial activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

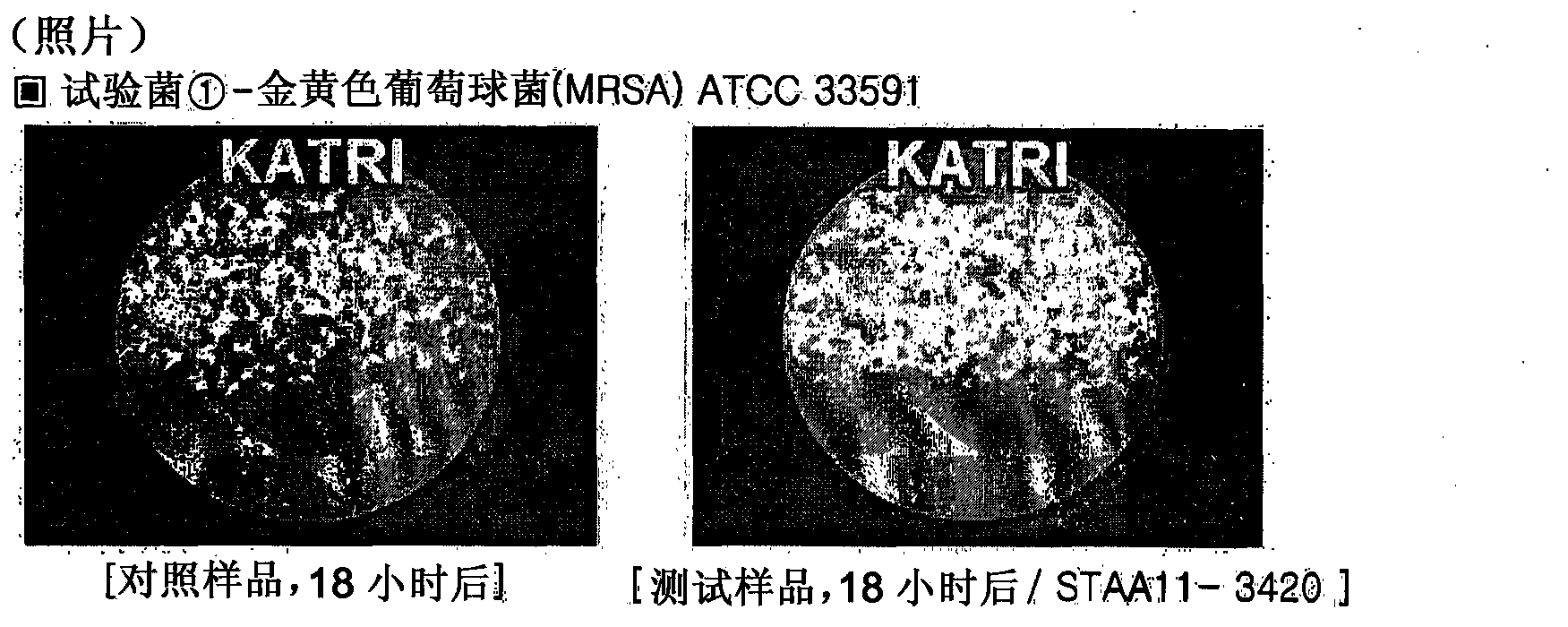

Image

Examples

preparation Embodiment 1)

[0041] *Preparation of forsythia extract

[0042] Four P.P. nonwoven bags each containing 2 kg of pulverized powder of forsythia were put into a high pressure decocter, and 20 kg of water was added. After boiling at 130 °C for 3 hours, the decoction was pressurized in a hydraulic linkage to yield 15 kg of extract. Manufactured by concentrating it to 5kg through two rounds of filtration through a 5 micron filter.

[0043] This procedure was continued until 65 kg of concentrated extract was obtained.

preparation Embodiment 2~4)

[0045] *Preparation of honeysuckle, ginkgo leaf and cinnamon bark extracts

[0046] Concentrated extracts of honeysuckle, ginkgo leaves and cinnamon bark were prepared in a similar manner to Preparation Example 1, respectively.

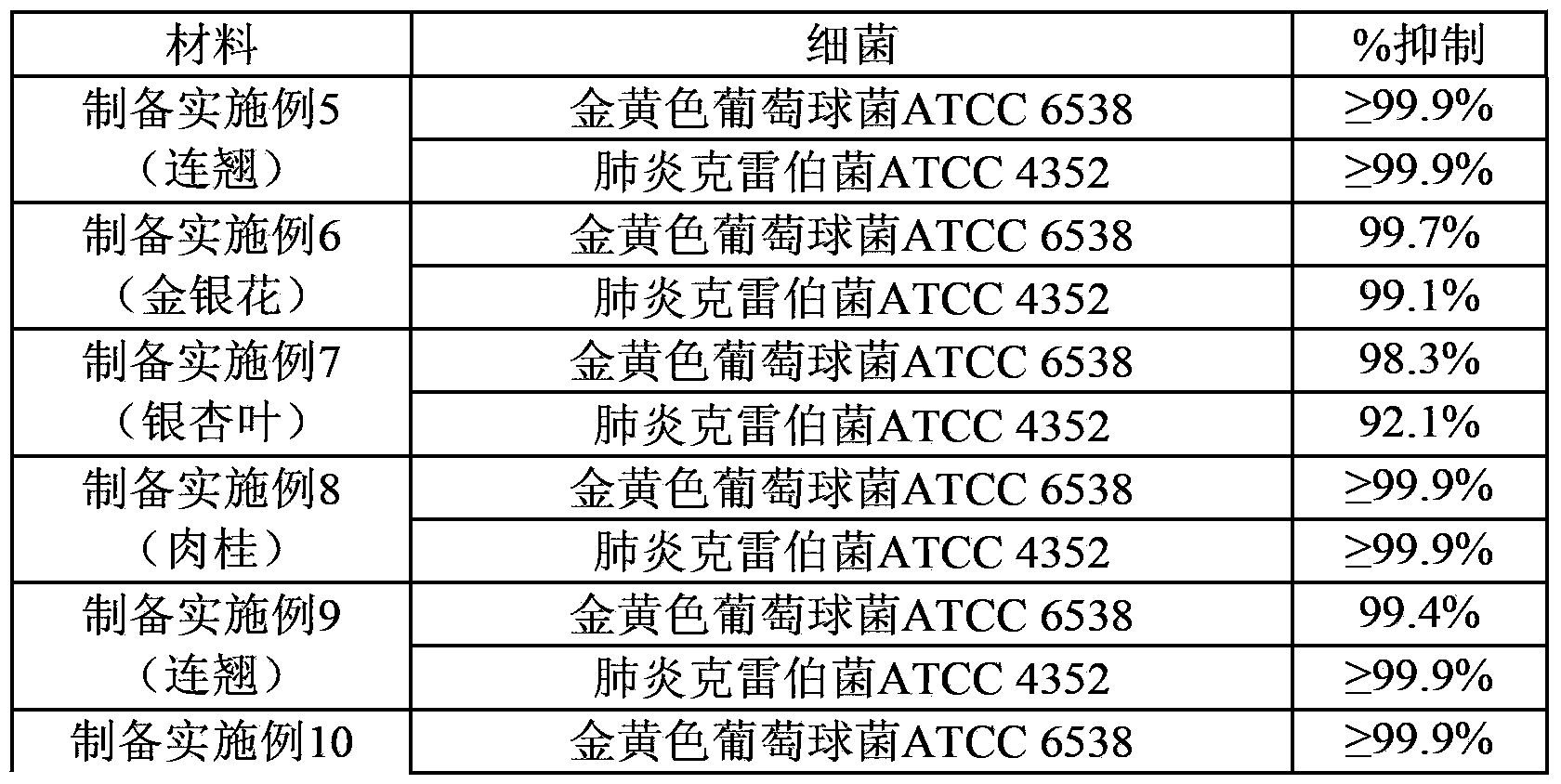

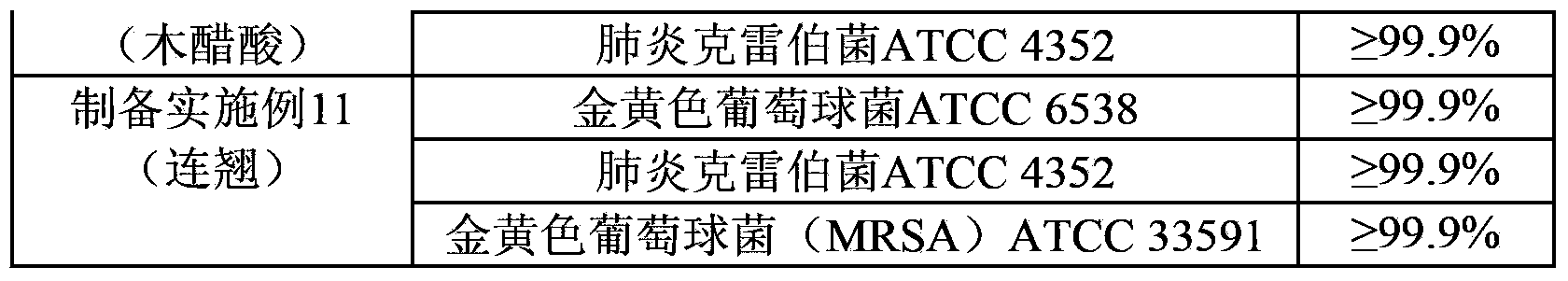

preparation Embodiment 5~8)

[0048] Each of the extracts prepared in Preparation Examples 1 to 4 was mixed with a polypropylene substrate in an amount of 2 wt %, and then dried in a rotary hot air dryer at 60° C. for 2 hours to obtain a coated substrate.

[0049] Using a bench spinner, 2 kg of the coated substrate was spun in a typical fashion at 225°C to produce 150 denier / 28 filaments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com