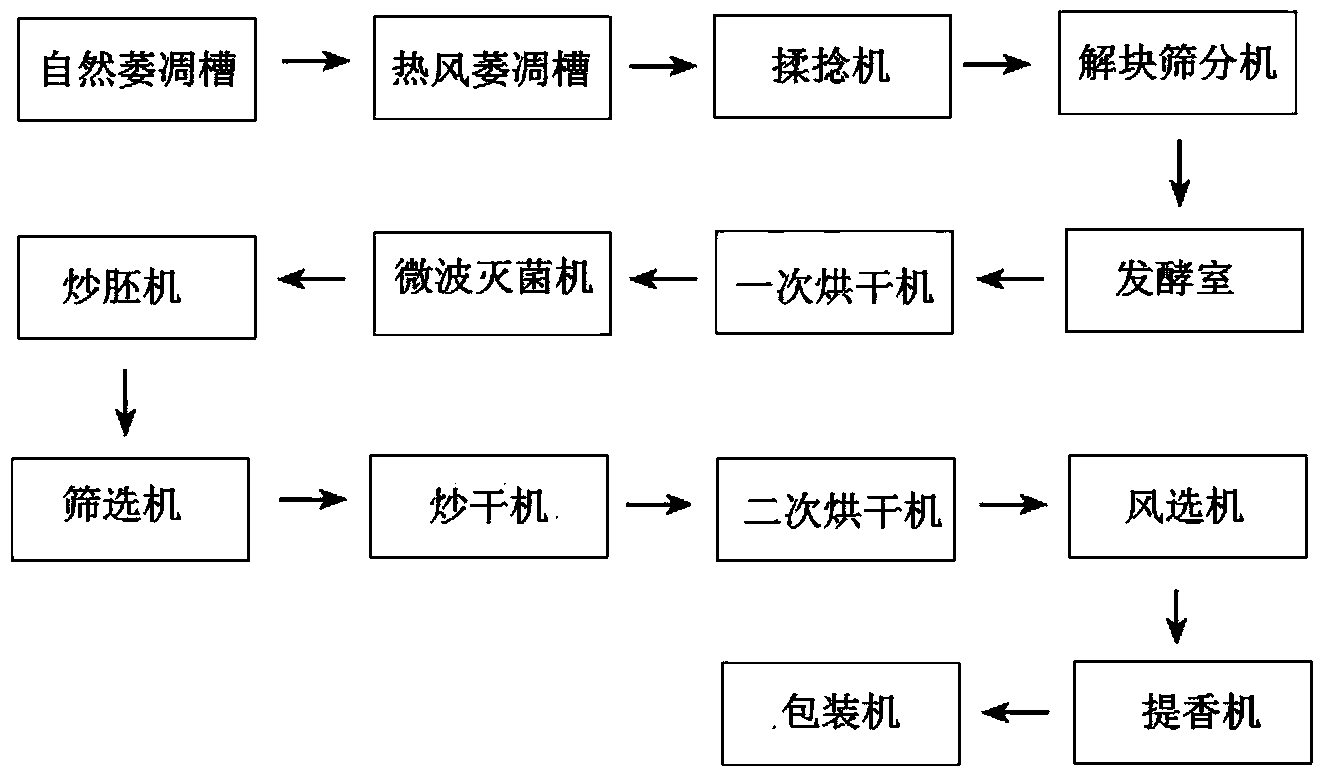

Spiral black tea (red sunglo) production system

A screw-shaped black tea, production system technology, applied in tea treatment before extraction, etc., can solve the problems of low production capacity, unsatisfactory tea preparation methods, etc., and achieve the effect of bright appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: The making of a kind of screw-shaped black tea (red pine) (spring tea)

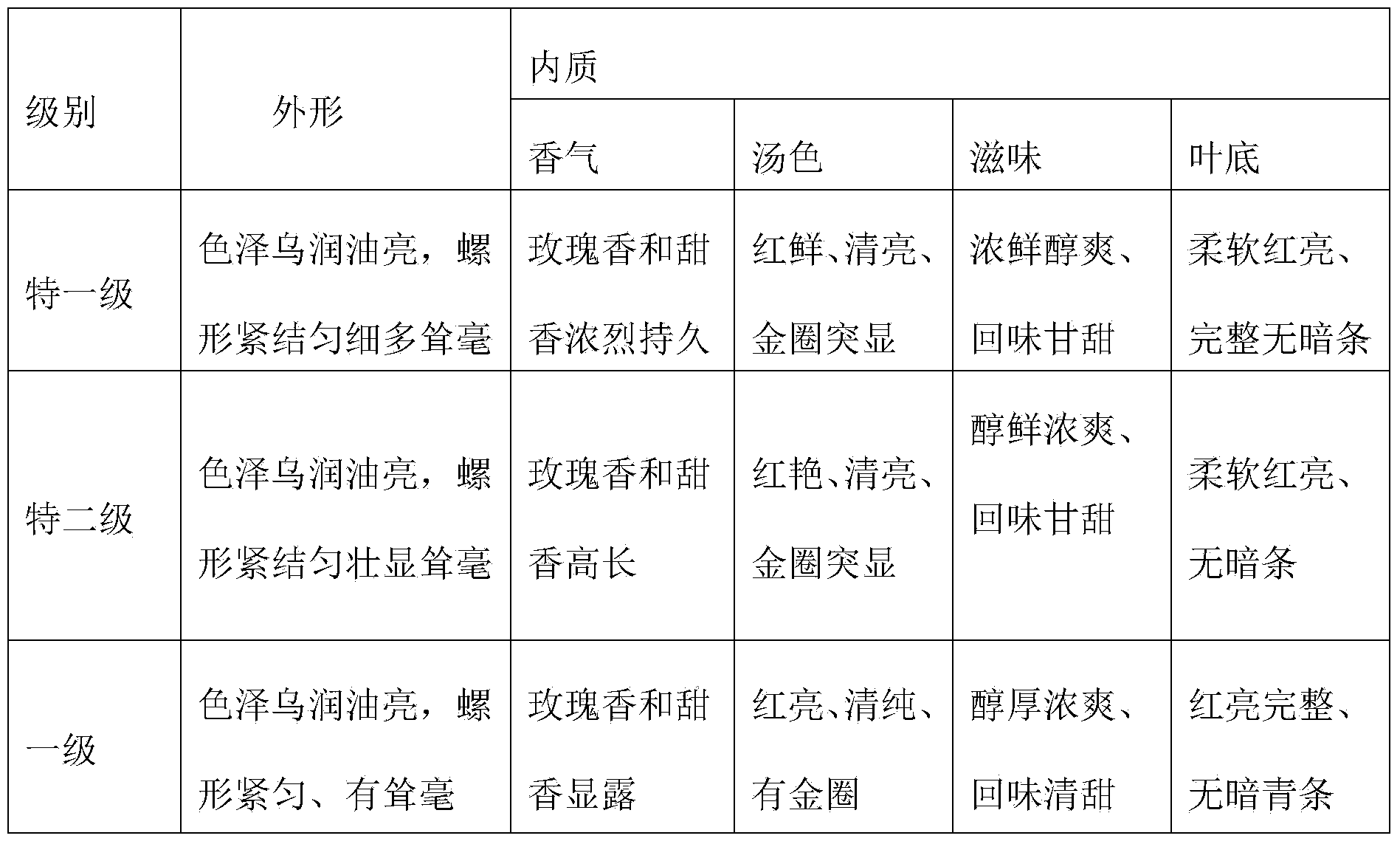

[0036] 1. Picking of fresh leaves: picking standard, special first-level standard, one bud and one leaf first development; special second level, one bud and one leaf to one bud and two first leaves;

[0037] 2. Natural withering: In the natural withering tank, at room temperature, spread and wither on bamboo mats, the thickness of the leaves of natural withering is 4-5 cm, the time is 8-10 hours, and the temperature is 18-25°C.

[0038] 3. Hot air withering: hot air is used to wither in the hot air withering tank, the temperature of the air inlet of the withering tank is 40-45°C, the temperature of the tank body is 38-40°C, the temperature of the withered leaves is 36-38°C, and the time is 6-7 hours.

[0039] 4. Motorized kneading: use Zhejiang Shangyang Machinery Co., Ltd. 6CR-55 tea kneading machine for kneading, kneading speed 30-35 rpm, time 45-50 minutes. Pressurization method: ...

example 2

[0052] Example 2: Production of a screw-shaped black tea (red pine) (summer tea)

[0053] 1. Picking fresh leaves: tea tree buds and leaves are easy to age in summer, so the tenderer the buds and leaves are, the better. The picking standard should be controlled at one bud and one leaf or one bud and two leaves. Too old buds and leaves are not easy to shape due to high cellulose content, and the taste is not fresh.

[0054] 2. Natural withering: In the natural withering tank, due to the high temperature in summer, the indoor temperature is 22-25°C, and the thickness of the spread leaves is slightly thinner to 3-4 cm. The withering time is shortened to 7-8 hours. If the time is long, it will easily lead to the phenomenon of dry buds and leaves, which will affect the shape.

[0055] 3. Hot air withering: In the hot air withering tank, the temperature of the tank body drops to within 36-38°C, the leaf temperature is about 34-36°C, and the time is 3-4 hours. This withering state ...

example 3

[0069] Example 3: Production of a screw-shaped black tea (red pine) (autumn tea)

[0070] 1. Picking of fresh leaves: The buds and leaves in autumn have a relatively long growth period and are easy to lignify. Therefore, it is advisable to basically control the picking standard of one bud and one leaf. The quality of the red usnea bixia tea produced by this standard is But also excellent.

[0071] 2. Natural withering: In the natural withering tank, the temperature is controlled between 22-24°C, the withering time is 6-7 hours, and the thin spread is 3-4 cm.

[0072] 3. Hot air withering: In the hot air withering tank, the temperature of the withered leaves is between 34-35°C for 3-4 hours.

[0073] 4. Motorized kneading: Zhejiang Shangyang Machinery Co., Ltd. 6CR-55 tea kneading machine is used; the kneading time is between 38-40 minutes, and the pressure is kept consistent with summer tea, and low-pressure kneading should also be used.

[0074] 5. Deblocking and screening:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com