Gluten-free instant noodles, preparation method and formula thereof

A gluten-free and noodle-free technology, which is applied in the field of deep processing of food, can solve the problems of people with gluten protein allergy and other problems, and achieve the effects of fine and smooth taste, reduced energy consumption and good appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

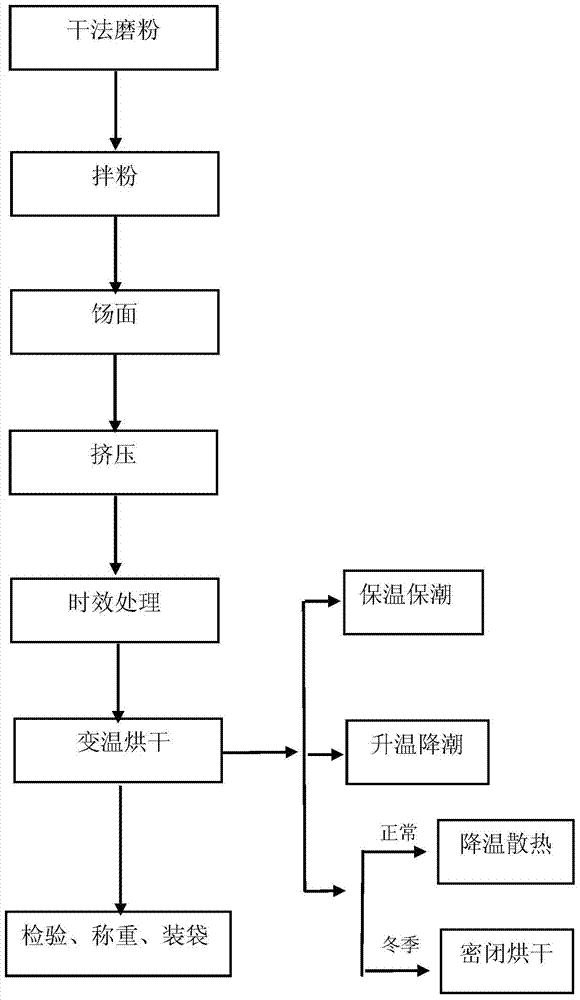

Method used

Image

Examples

Embodiment 1

[0057] Raw material formula of white rice grain noodles: 100 parts of Northeast japonica rice white rice noodles;

[0058] Step 1, dry milling: Weigh 100 parts of Northeast japonica rice white rice flour, sieve to remove impurities, and obtain a dry powder with a specification of 120 mesh;

[0059] Step 2, mixing powder: mix 100 parts of dry powder obtained in step 1 with 30 parts of purified water, and use a powder mixing machine to mix the powder until the powder is evenly mixed;

[0060] Step 3, noodles: cook noodles for 40 minutes to get noodles;

[0061] Step 4. Extrusion: Put the prepared noodles into the feed port of the screw extruder to perform primary extrusion and secondary extrusion in sequence;

[0062] The first-stage extrusion: the central temperature of the extrusion cavity is 150°C, the pressure is 10MPa, the flour noodles pass through the extrusion cavity, and are extruded at the die mouth to obtain gelatinized and partially puffed thick noodles. The diamet...

Embodiment 2

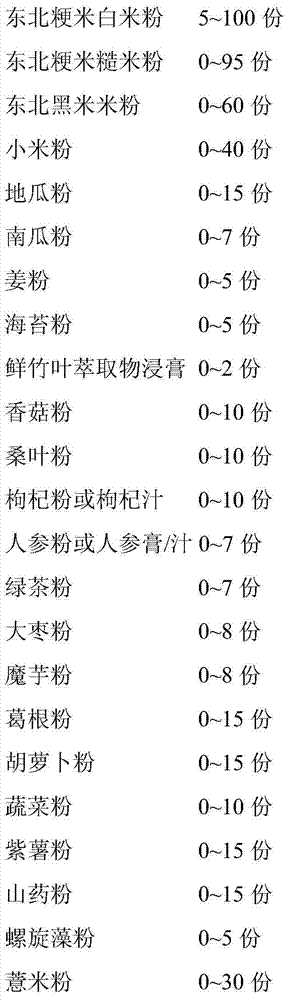

[0073] The following recipes can be used to obtain gluten-free instant noodles according to the method of this embodiment:

[0074] Raw material formula of mushroom and brown rice cereal noodles: 40-90 parts of northeast japonica rice brown rice flour, 5-15 parts of northeast japonica rice white rice flour, 3-10 parts of mushroom powder;

[0075] Raw material formula of brown rice cereal noodles: 5-20 parts of Northeast Japonica rice white rice flour, 80-95 parts of Northeast Japonica rice brown rice flour;

[0076] Taking the raw material formula of brown rice cereal noodles as an example, further explanation is given below. Compared with Example 1, only the variable temperature drying conditions are different in this embodiment, and the specific methods are as follows:

[0077] Specific steps are as follows:

[0078] Step 1, dry milling: Weigh 20 parts of Northeast Japonica Rice White Rice Flour and 80 parts of Northeast Japonica Rice Brown Rice Flour, sieve to remove impur...

Embodiment 3

[0093]Raw material formula of bamboo juice cereal noodles: 5-20 parts of Northeast japonica rice white rice flour, 80-95 parts of Northeast japonica rice brown rice flour, 0.1-2 parts of fresh bamboo leaf extract;

[0094] Compared with Example 1, the extruding conditions and variable temperature drying conditions of the present embodiment are different, and the specific methods are as follows:

[0095] Step 1, dry milling: Weigh 20 parts of Northeast Japonica Rice White Rice Flour and 80 parts of Northeast Japonica Rice Brown Rice Flour, sieve to remove impurities, add 0.1 part of fresh bamboo leaf extract, and stir evenly to obtain a dry powder with a specification of 120 mesh;

[0096] Step 2, mixing powder: mix the dry powder obtained in step 1 with 30 parts of pure water, and use a powder mixing machine to mix the powder until the powder is evenly mixed;

[0097] Step 3, noodles: cook noodles for 40 minutes to get noodles;

[0098] Step 4. Extrusion: Put the prepared noo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com