Hand-operated back-washing filter with filter screen

A filter and backwashing technology, applied in the field of water treatment, can solve the problems of loose overall structure, large system influence and high overall cost, and achieve the effect of light conversion, simple overall structure and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

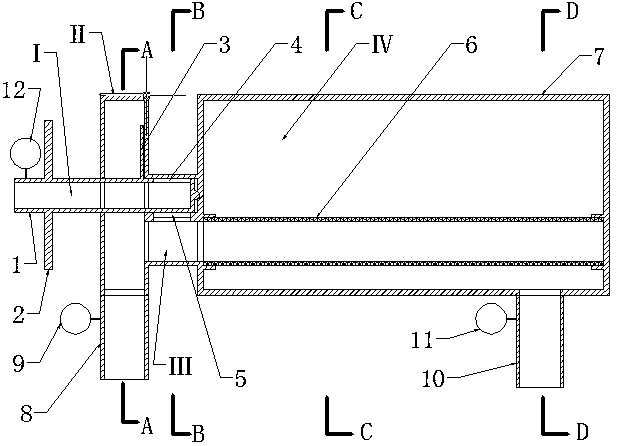

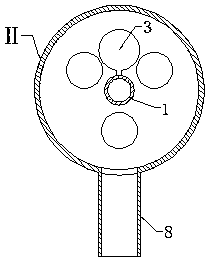

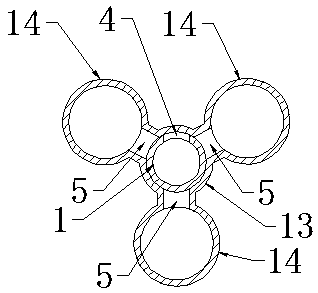

[0026] refer to Figure 1 to Figure 9 . A manual backwash screen filter, which is composed of a sewage discharge assembly I, a water inlet chamber II, an intermediate chamber III, and a filter chamber IV; the water inlet chamber II is a hollow cylinder, and the water inlet chamber II is provided with a water inlet pipe 8 , the water inlet pipe 8 is provided with a water inlet pressure gauge 9, and three orifices are opened on the bottom of the water inlet chamber II to communicate with the inlets of the three filter elements 6 through the middle chamber III; the middle chamber III is set between the water inlet chamber II and the filter chamber IV Between them, the center of the middle chamber III is a central cylinder 13, along which the center of the central cylinder 13 is a circumference, and three circular tubular connection channels 14 are evenly distributed, and the three connection channels 14 are connected to the water inlet chamber II and the three filter elements 6....

Embodiment 2

[0031] refer to Figure 13 , Embodiment 2 is a manual backwashing screen filter, the basic structural features are similar to Embodiment 1, the difference is that the water inlet pipe 8 is located on the side circumference of the water inlet chamber II, and the outlet pipe 10 is located on the bottom surface of the shell 7. Parts of Embodiment 2 having the same structure as Embodiment 1 are denoted by the same reference numerals and will not be described again. The principle and implementation process of this embodiment are also the same as those of the first embodiment, so its description is omitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com