Apparatus and method for preparing nanomaterials by supercritical-solvothermal combination

A nanomaterial and supercritical technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of difficult to obtain pure products, difficult to remove reaction aids, cumbersome post-treatment processes, etc. problems, to achieve the effect of broad industrialization prospects, high production efficiency, and huge application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

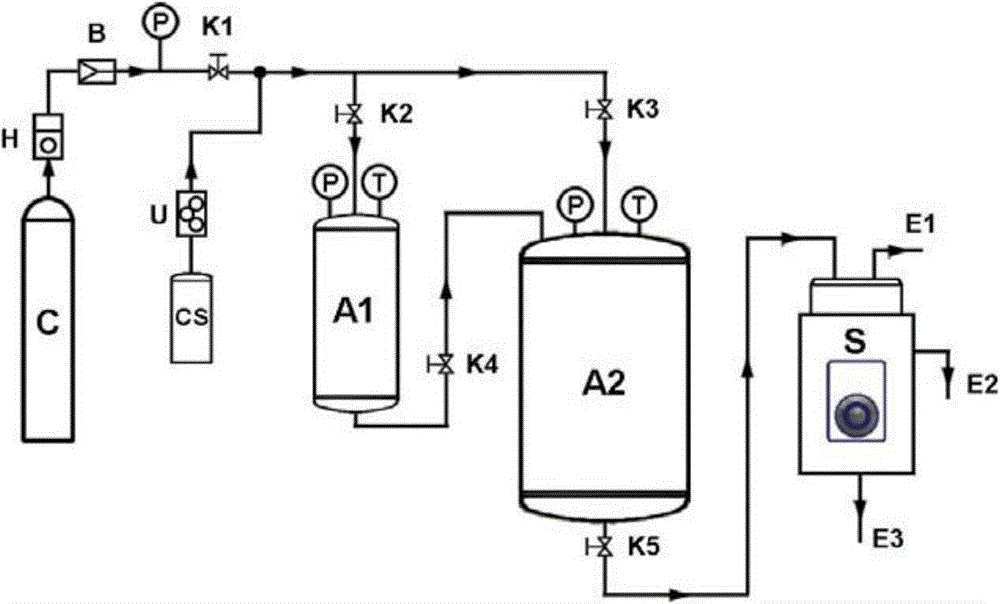

[0050] When the raw material is completely soluble in the entrainer. Nanomaterials can be prepared following an example method of supercritical-solvothermal combination.

[0051] (1) Before the operation starts, install the sintering disc with microporous structure on the bottom of the cylindrical metal basket, and put the cylindrical metal basket into the reaction kettle A2; put the raw materials into the entrainer container CS and dissolve them in the entrainer , to form a homogeneous solution; then connect the pipeline, test the air tightness, and carry out the preparation operation;

[0052] (2) Close the valves K1-K5, the high-purity carbon dioxide in the cylinder C is first cooled by the carbon dioxide cooler H, and after reaching the temperature range required for supercritical conditions, it enters the carbon dioxide pump B and pressurized by the pump to make the carbon dioxide reach a supercritical state , and then controlled by the valve K1 to enter the subsequent r...

Embodiment 2

[0059] If the raw material is not completely soluble in the entrainer, but the target substance components in the raw material are soluble in the entrainer, nanomaterials can be prepared according to the example method of supercritical-solvothermal combination as follows.

[0060] (1) Before the operation starts, put the raw materials into the cylindrical metal basket, install the sintering plate with microporous structure at the bottom of the cylindrical metal basket, put the metal basket into the reaction kettle A1; connect the pipeline, test the gas Tightness, for preparation operations;

[0061] (2) Close the valves K1-K5, the high-purity carbon dioxide in the cylinder C is first cooled by the carbon dioxide cooler H, and after reaching the temperature range required for supercritical conditions, it enters the carbon dioxide pump B and pressurized by the pump to make the carbon dioxide reach a supercritical state , and then controlled by the valve K1 to enter the subsequen...

Embodiment 3

[0068] If the raw material is not soluble in the entrainer, nanomaterials can be prepared according to the example method of supercritical-solvothermal combination as follows.

[0069] (1) Before the operation starts, put the raw materials into the cylindrical metal basket, install the sintering plate with microporous structure at the bottom of the cylindrical metal basket, put the metal basket into the reaction kettle A2; connect the pipeline, test the gas Tightness, for preparation operations;

[0070] (2) Close the valves K1-K5, the high-purity carbon dioxide in the cylinder C is first cooled by the carbon dioxide cooler H, and after reaching the temperature range required for supercritical conditions, it enters the carbon dioxide pump B and pressurized by the pump to make the carbon dioxide reach a supercritical state , and then controlled by the valve K1 to enter the subsequent reaction process;

[0071] (3) The entrainer in the entrainer container CS is pressurized by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com