Patents

Literature

34results about How to "Preparation to meet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

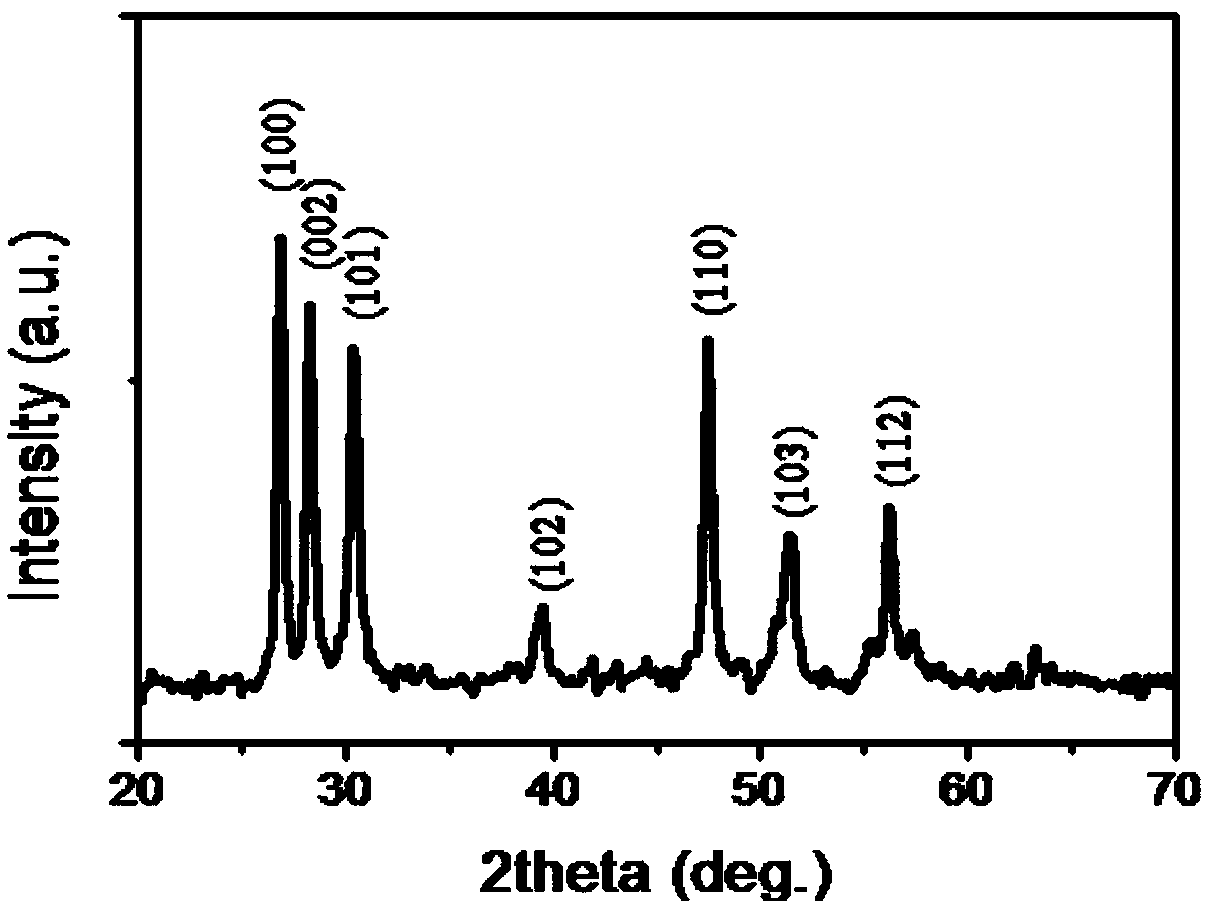

Highly compact ceramic ball of silicon carbide and preparation process thereof

InactiveCN102311268AHigh densityChemically stableSodium carboxymethylcellulosePVA - Polyvinyl alcohol

The invention relates to a highly compact ceramic ball of silicon carbide and a preparation process thereof. The ceramic ball is prepared through carrying out steps of batch mixing, spray granulation, seed production, balling, and sintering on the following raw materials: 85-95% of a main material fine silicon carbide powder, 4-10% of a high char yield phenolic resin, 1-5% of a sintering aid, 1-10% of the weight percentage of the main material of a binder, and 0.5-3% of the weight percentage of the main material of a dispersant, wherein the binder is at least one of polyvinyl alcohol, dextrin, and carboxymethyl cellulose, and the dispersant is at least one of polyethylene glycolm, tetramethylammonium hydroxide, an aluminophosphate, and polyacrylic acid. According to the invention, active beneficial effects comprise that: 1, the ceramic ball of silicon carbide has the advantages of high density and stable chemical property; 2, the preparation process of the invention allows preparationof ceramic balls of silicon carbide with particle sizes of various specifications to be satisfied, so the ceramic balls with the particle size having a wide range of 1-50mm to be produced; and 3, theprocess is simple, one-time investment is less, and production expansion is easy.

Owner:HENAN XINDAXIN SCI & TECH

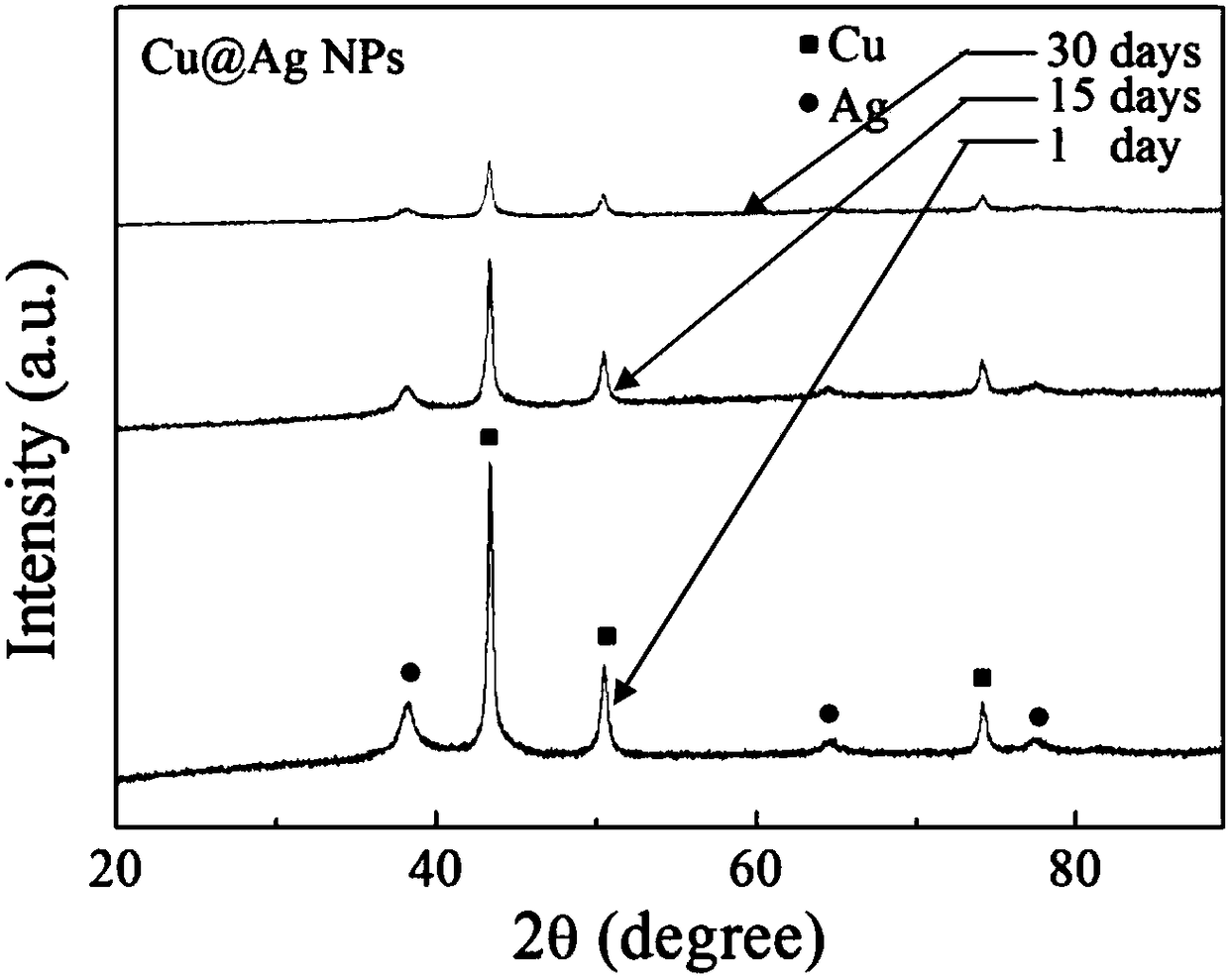

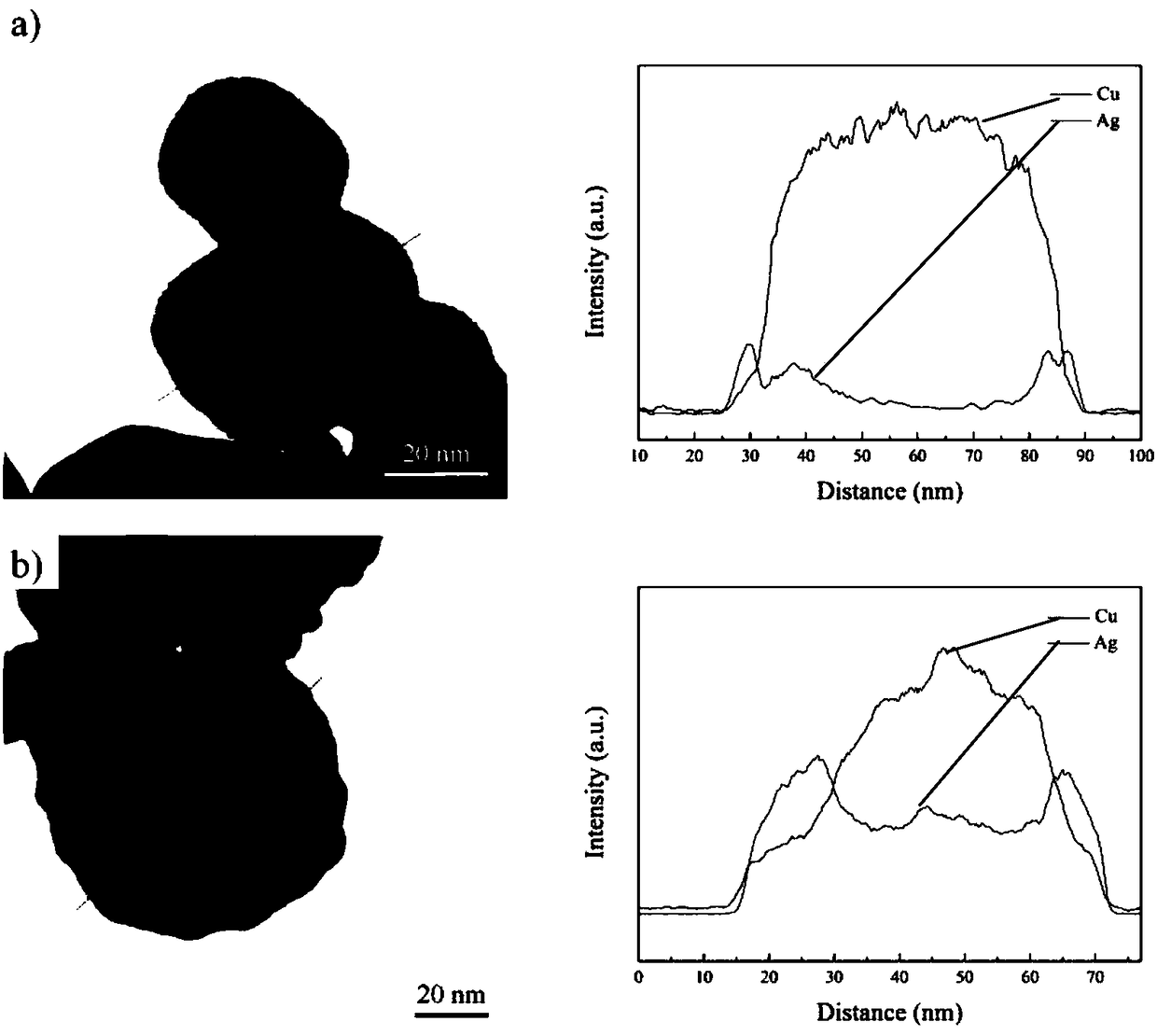

Material for RFID (Radio Frequency Identification) antenna conductive pattern

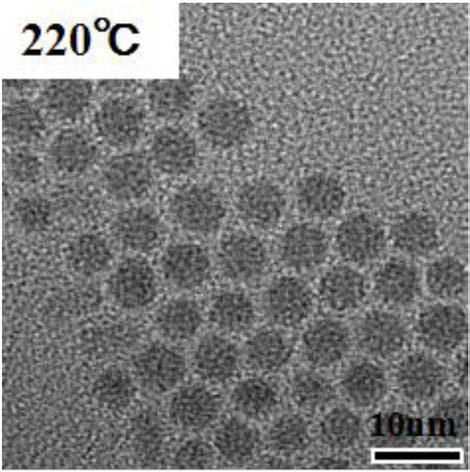

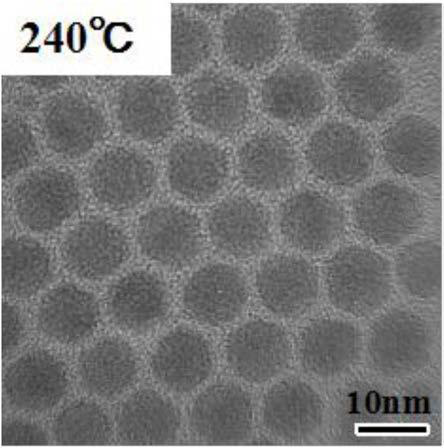

PendingCN108084799ARich in mineralsLower resistanceMaterial nanotechnologyTransportation and packagingStencil printingPrinting ink

The invention provides a material for an RFID (Radio Frequency Identification) antenna conductive pattern. The material for the RFID antenna conductive pattern has the following specific characteristics that the material is metal nano-particles which are of core-shell structures, wherein the inner cores are Cu particles of about 50 nm, and an Ag layer coats the surfaces of Cu through a composite method of displacement and chemical deposition; Cu@Ag nano-particles, absolute ethyl alcohol and deionized water are mixed to prepare conductive printing ink with the solid content of about 70 percent;the material is obtained through metal stencil printing and sintering. Antenna patterns with different thicknesses can be manufactured by the material by adopting metal stencil printing so as to meetdifferent impedance requirements of antennae of various frequency bands. The Cu@Ag nano-particles have the characteristics of low impedance, high conductivity, controllable Ag layer thickness and thelike; compared with Cu conductive printing ink, the Cu@Ag nano-particles have high oxidation resistance; compared with pure Ag or Au conductive printing ink, the cost is greatly reduced; optimal sintering performance can be realized by controlling the thickness of the Ag layer; moreover, a preparation process of the material is simple and convenient; a printing ink solvent is environment-friendlyand renewable, and has a very great application prospect in the field of conductive printing ink for the RFID antenna.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

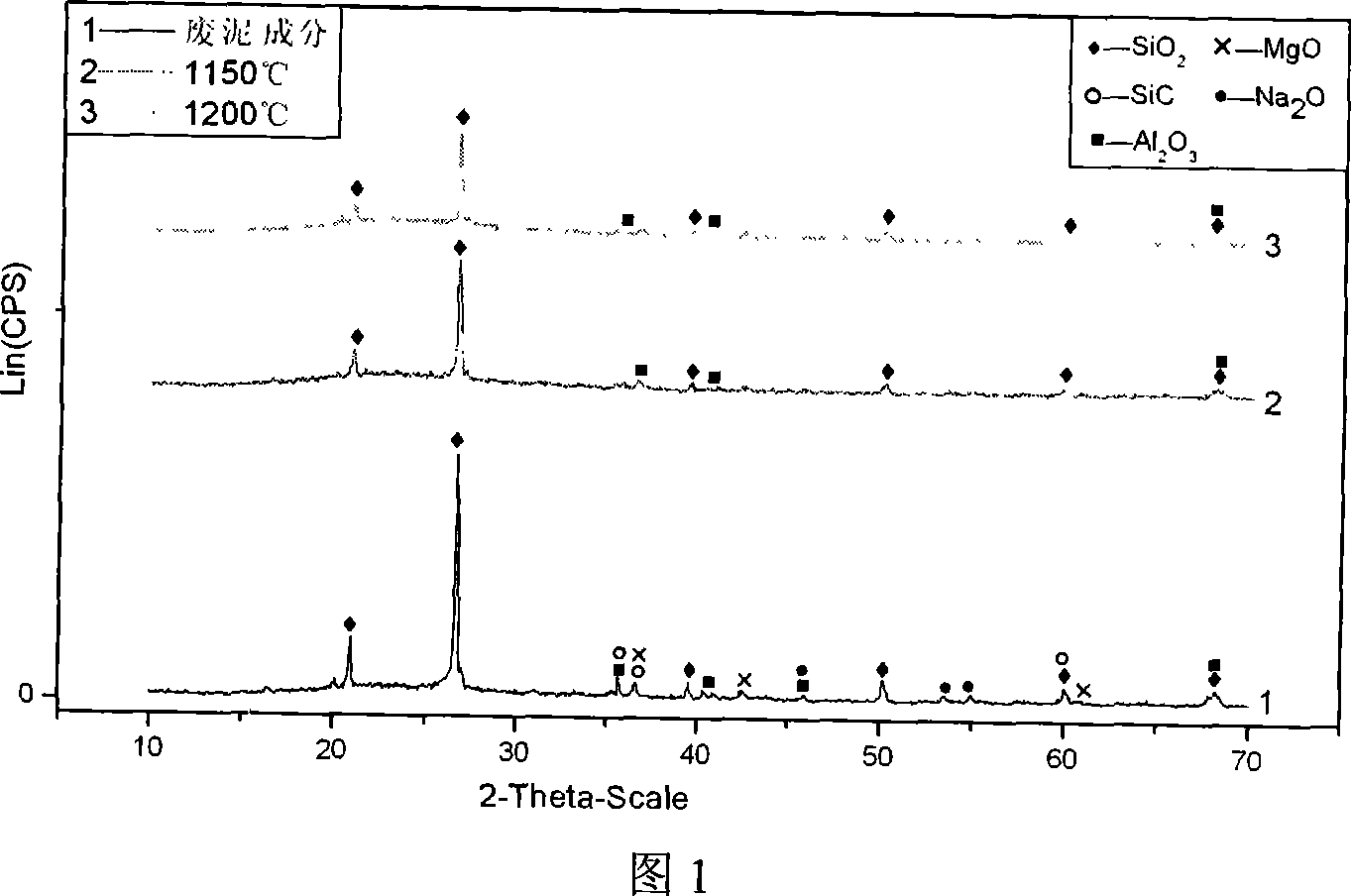

Ceramic-base high-strength lightweight buoyancy material

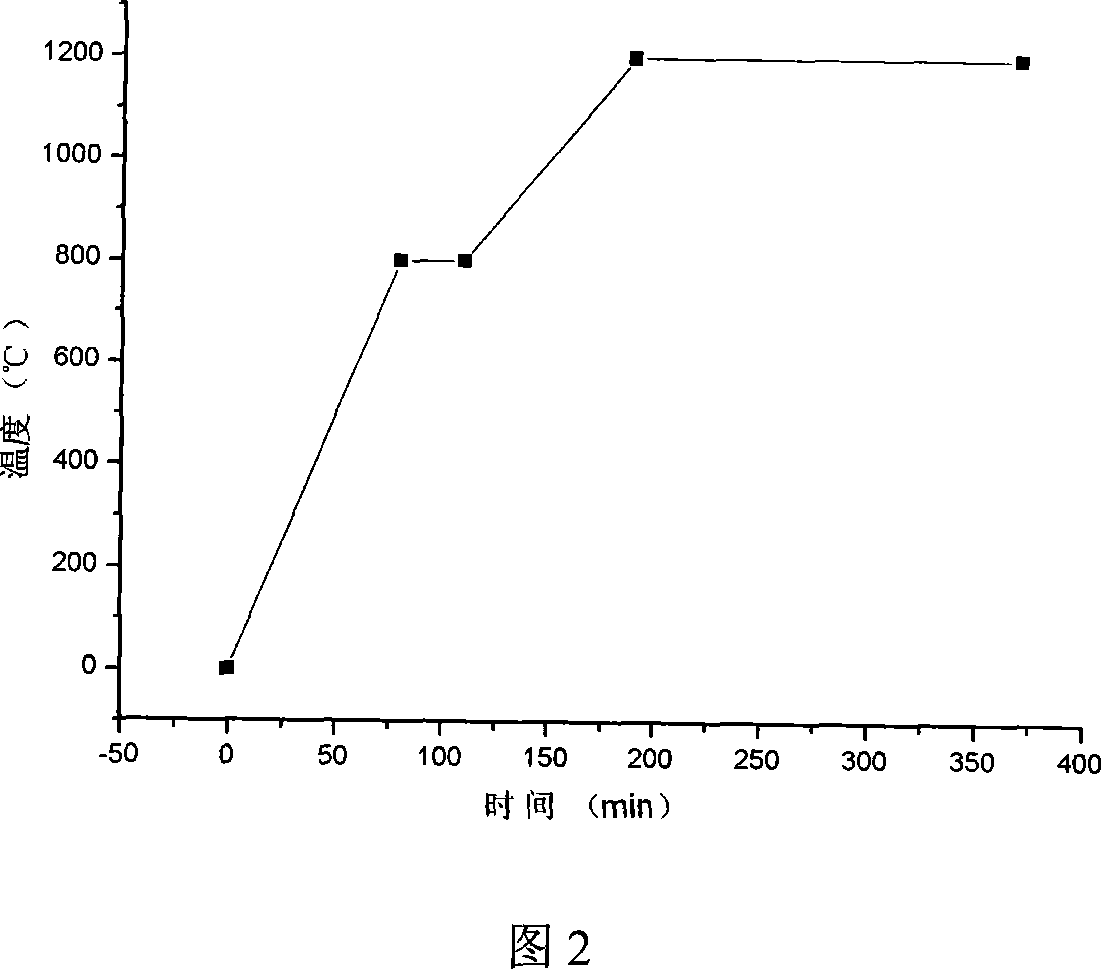

The present invention discloses a preparation method for new type ceramics-based buoyancy material with light weight and high intensity, wherein the polishing waste sludge from the ceramics factory serves as the main material, the porous ceramic material which has high sealed porosity content and prepared by dry pressing, injection moulding, atmospheric pressure sintering, high temperature chemical blowing process serves as the matrix of the new type ceramics-based buoyancy material, and epoxy resin serves as the fortified outer wall. Compared with the prior art, the buoyancy material of the present invention has excellent endurance and weathering resistance, sea-water corrosion resistance, aging resistance, small specific absorption of volume, high mechanical strength, simple preparation process, low cost and convenience for industrialisation. The internal pore of the porous ceramics has an uniform distribution and the sealed porosity is more than 95% due to the high temperature foaming in situ. The new type buoyancy material has low density and high compression strength. The porous ceramic material prepared by sintering at 1180 DEG C has a density of 0.35g / cm<3> and a compression strength of more than 7 MPa. The buoyancy material which is modified by epoxy resin has a density of 0.52g / cm<3> and a compression strength of more than 20 MPa.

Owner:OCEAN UNIV OF CHINA

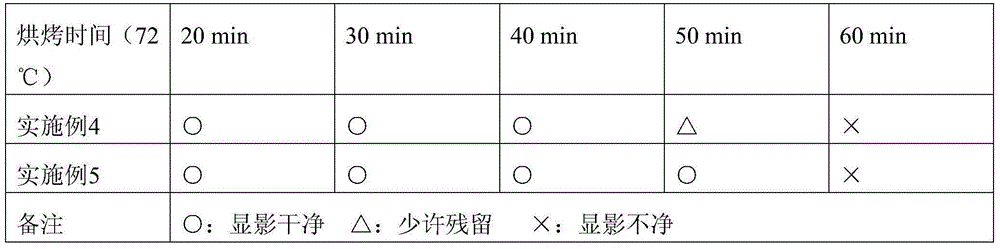

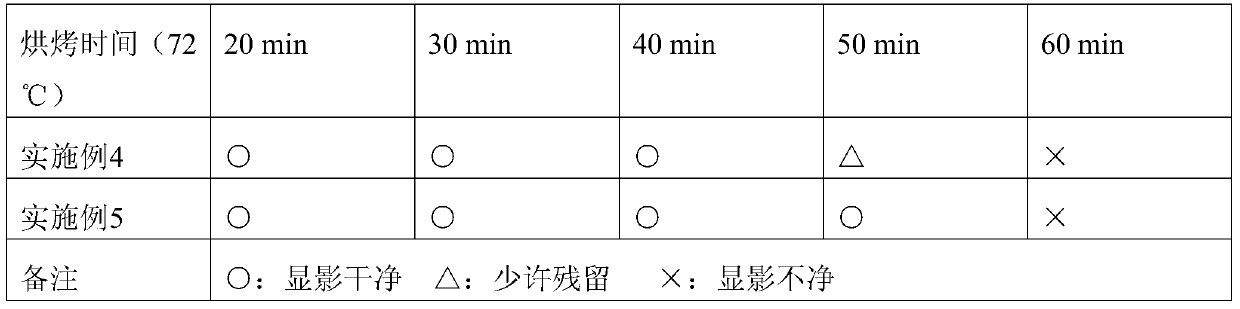

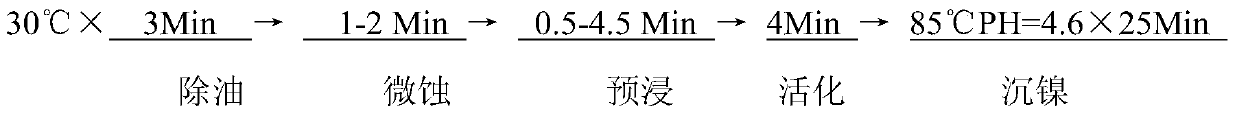

Matt-white immersion-gold-resistant, anti-cracking and light-sensing solder mask material and preparation method thereof

ActiveCN105137716AImprove heat resistanceGood chemical resistancePhotosensitive materials for photomechanical apparatusAcrylic resinFirming agent

The invention discloses a matt-white immersion-gold-resistant, anti-cracking and light-sensing solder mask material and a preparation method thereof. The matt-white immersion-gold-resistant, anti-cracking and light-sensing solder mask material mainly comprises a main agent and a curing agent, wherein the main agent comprises acrylic resin with a special function, acrylic resin, a photoinitiator, a dispersing agent, dibasic ester, fumed silica, barium sulfate, titanium dioxide and an antifoaming agent; the curing agent comprises thermocuring resin, a curing additive, melamine, a photocuring monomer, triglycidyl isocyanurate, titanium dioxide and dibasic ester. The prepared matt-white light-sensing solder mask material has high immersion gold resistance and yellowing resistance, and is more stable and reliable during normal technology use of a PCB (printed circuit board).

Owner:江门市阪桥电子材料有限公司

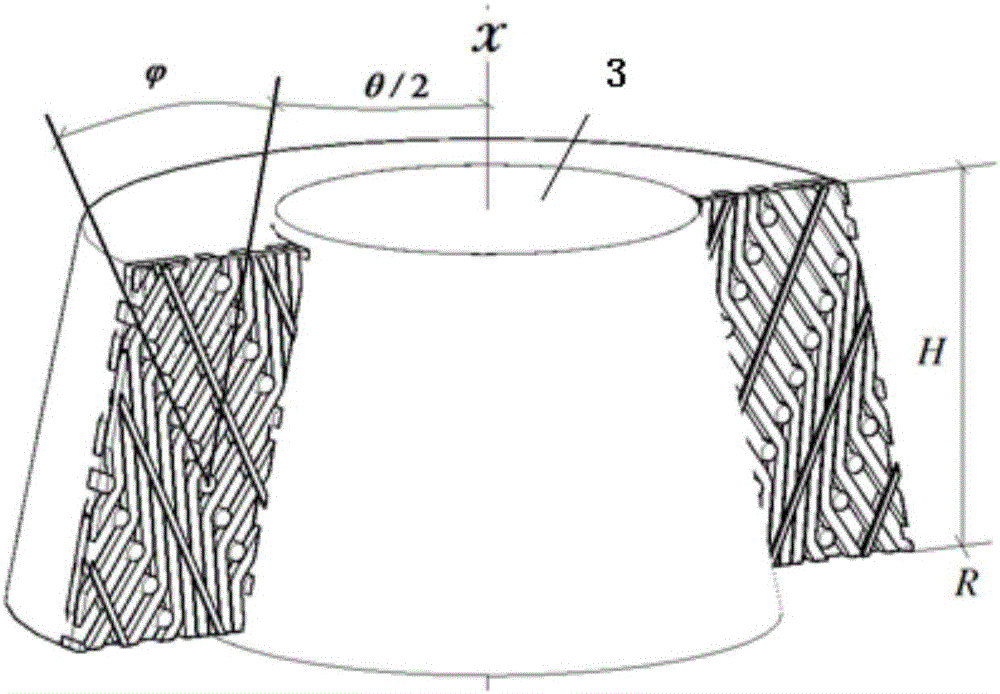

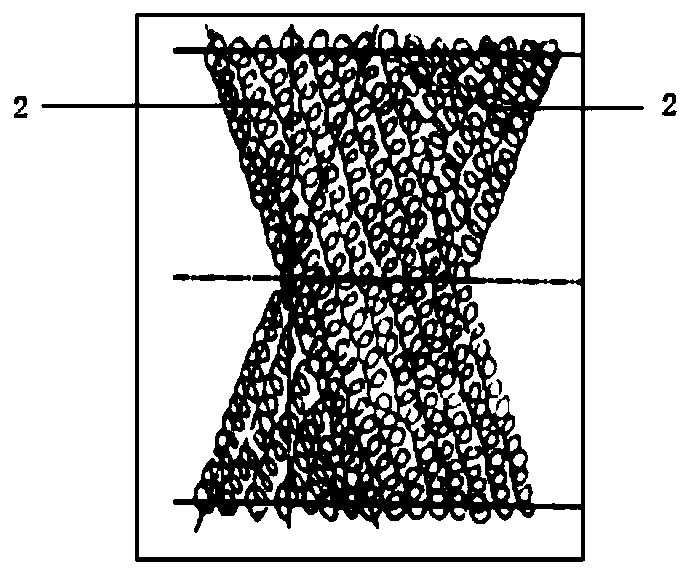

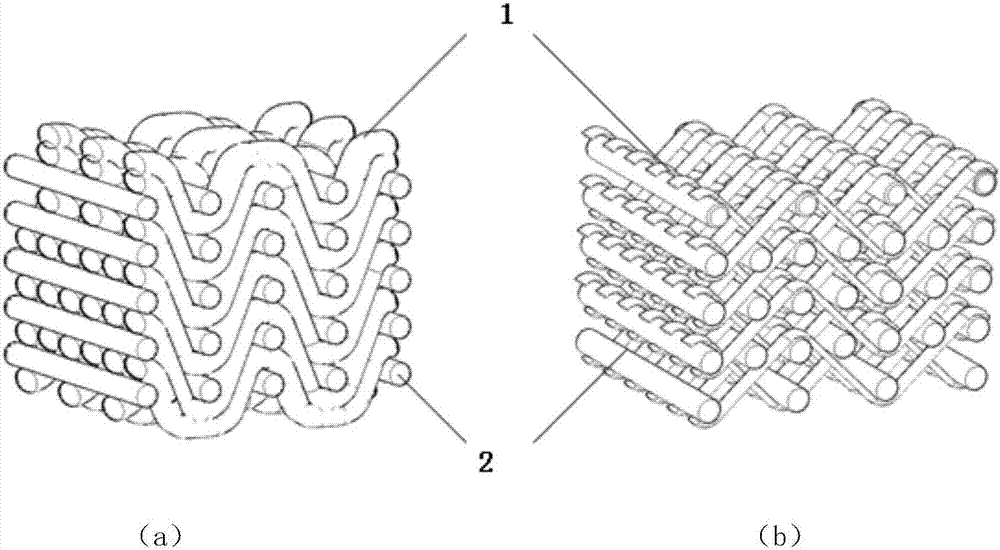

Molding preparation method for tackified preform of fiber layered-connection structure

The invention discloses a molding preparation method for a tackified preform of a fiber layered-connection structure. According to the molding preparation method for the tackified preform of the fiber layered-connection structure, the tackified perform is woven according to a mold through a knitting method. The molding preparation method for the tackified preform of the fiber layered-connection structure is applicable to preparation of the tackified perform which is high in thickness, large in size and complex in shape; the molding preparation method ahs the advantages of being great in structural design performance, good in tackified perform homogeneity, excellent in mechanical property, high in fiber volume fraction, complete in block construction, continuous in yarn bundle, stable and controllable in dimension, high in preparation precision and suitable for preparing tackified perform complex in shape.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Process for forming silicon carbide ceramic ball

InactiveCN109369189AHigh densityChemically stableCeramic shaping apparatusTetramethylammonium hydroxidePolyvinyl alcohol

The invention provides a silicon carbide ceramic ball. The silicon carbide ceramic ball is prepared by mixing, granulating, seeding, forming, sintering and grinding, production of seeds, forming, sintering and grinding from, by weight parts, a main ingredient and an auxiliary, wherein the main ingredient includes 87%-96% of silicon carbide fine powder, 5%-11% of high residual carbon phenolic resinand 1.2%-5% of sintering aid, wherein the sintering aid is at least one of B, C, B4C, Al2O3 and Y2O3. The auxiliary includes binder accounting for 0.9%-11% of the weight of the main ingredient and dispersing agent accounting for 0.5%-3.5% the weight of the main ingredient, and the binder is at least one of polyvinyl alcohol, dextrin and carboxymethyl cellulose; and the dispersing agent is at least one of polyethylene glycol, tetramethylammonium hydroxide, aluminophosphate, and polyacrylic acid. The silicon carbide ceramic ball has high density and stable chemical property; the silicon carbideceramic ball can meet the preparation of silicon carbide ceramic balls of multiple specifications, the range is wide, and the silicon carbide ceramic balls ranging from 1 mm to 50 mm can be produced.The one-time investment is small, and the production expansion is easy.

Owner:江苏高越高新科技有限公司

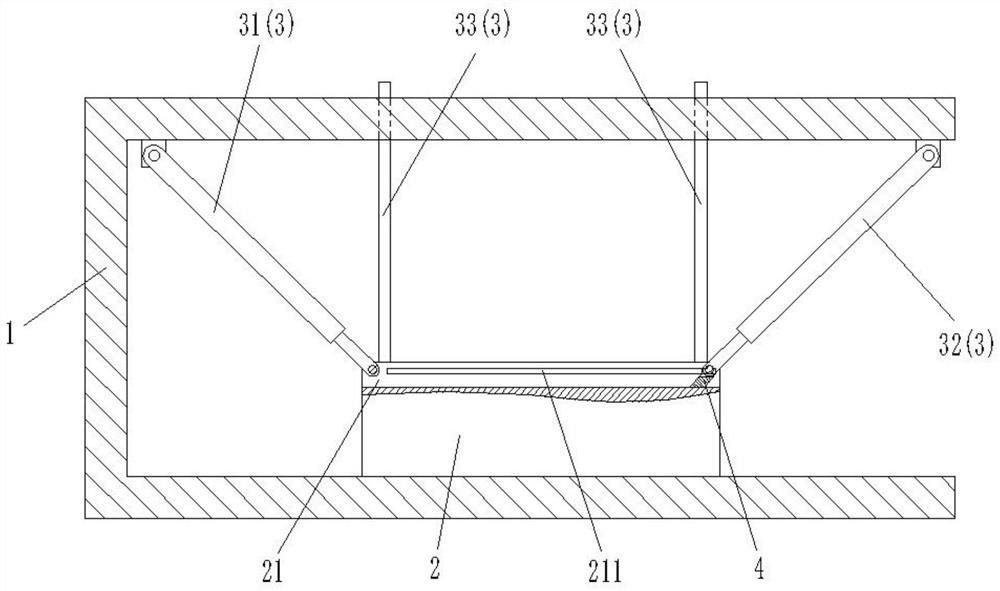

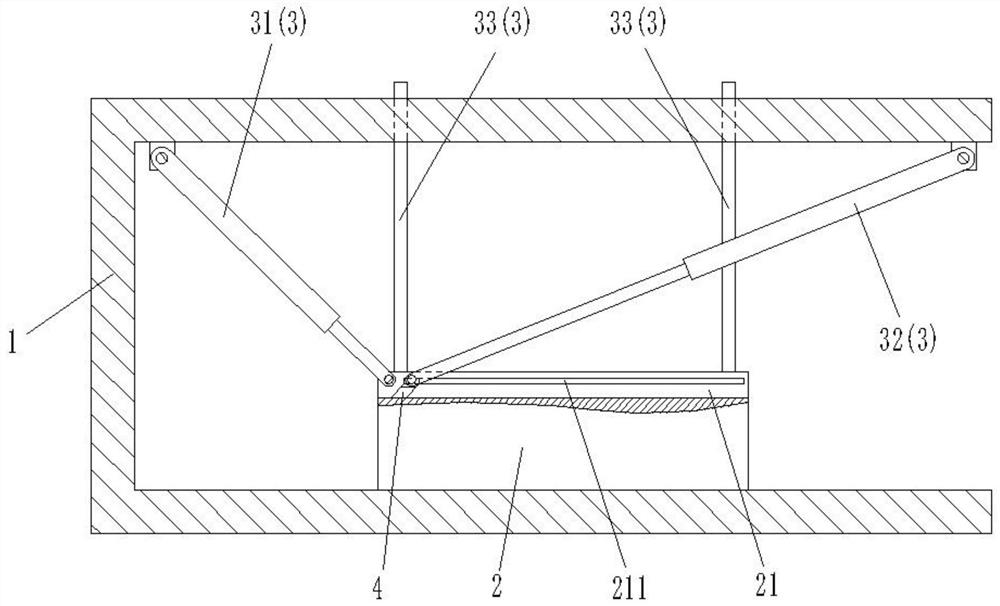

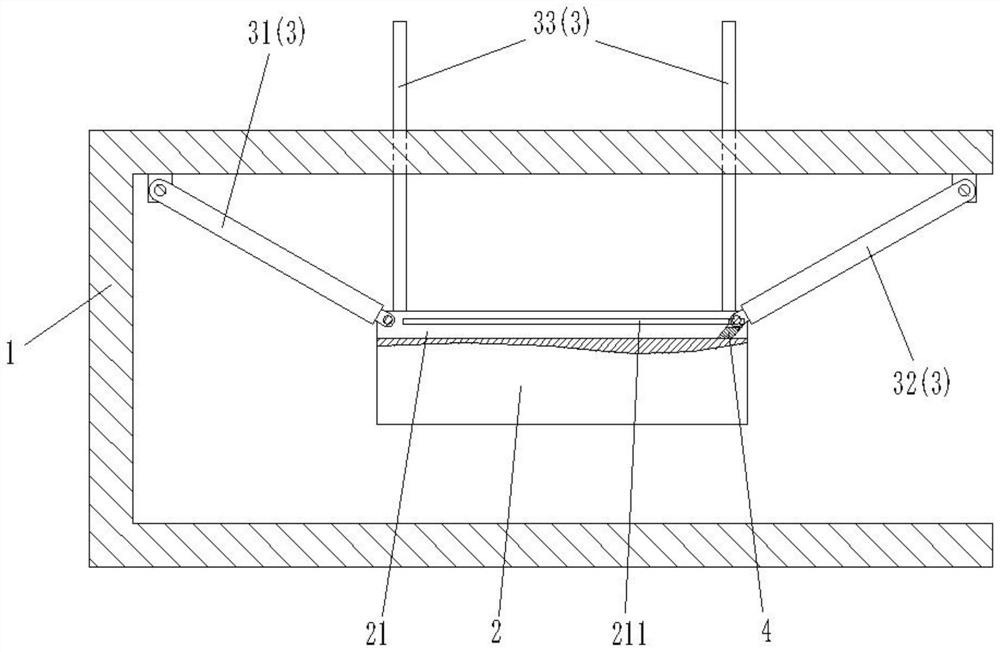

Aerated concrete block preparation system and preparation process

InactiveCN113119281AImprove efficiencyImprove efficiency and qualityDischarging arrangementMouldsStructural engineeringMechanical engineering

The invention discloses an aerated concrete block preparation system which comprises a support, a mold mechanism and a lifting mechanism, wherein the mold mechanism comprises a mold frame, a driving unit, connecting rings, connecting rods, sliding rods and mold side plates; the connecting rings are positioned on the mold frame and can rotate; the driving unit drives the connecting ring to rotate; the multiple mold side plates are arranged in the connecting ring and are sequentially arranged in the circumferential direction of the connecting ring to define a mold cavity, and the adjacent mold side plates are in sliding connection; and the sliding rods are located between the connecting rings and the mold side plates and are in sliding connection with the mold frame in the radial direction of the connecting rings, one end of each sliding rod is in sliding connection with the corresponding mold side plate in the horizontal direction, the other end of each sliding rod is rotationally connected with one end of the corresponding connecting rod, and the other end of each connecting rod is rotationally connected with the corresponding connecting ring. According to the aerated concrete block preparation system, preparation of aerated concrete blocks of different sizes can be met, rapid demolding can be achieved, and the preparation efficiency and quality of the aerated concrete blocks are improved.

Owner:王修东

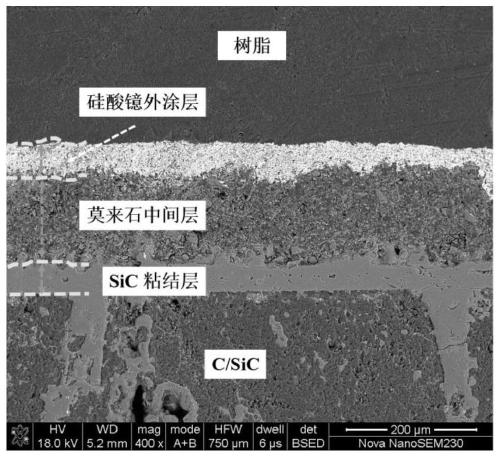

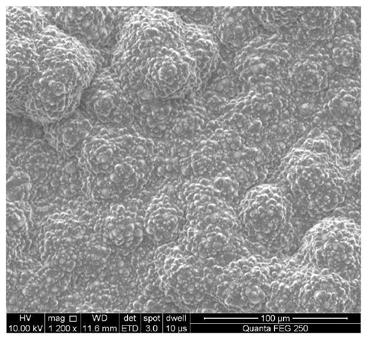

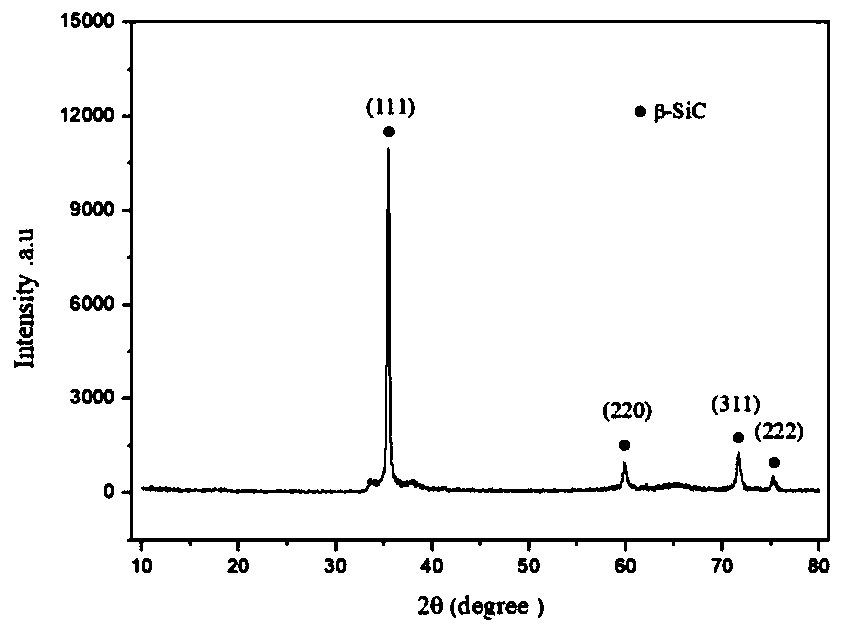

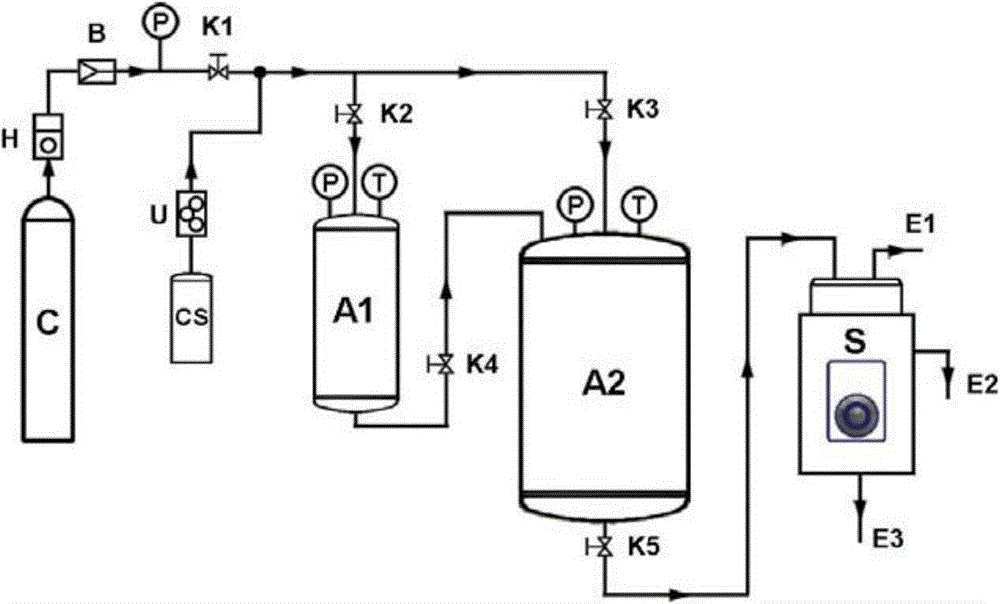

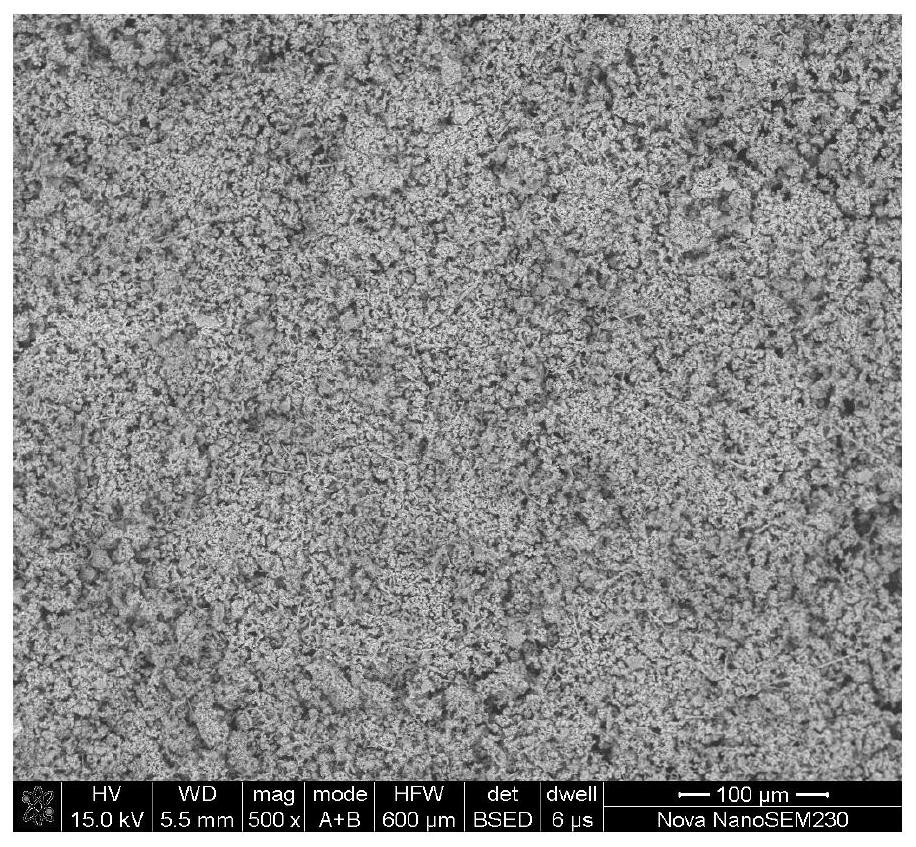

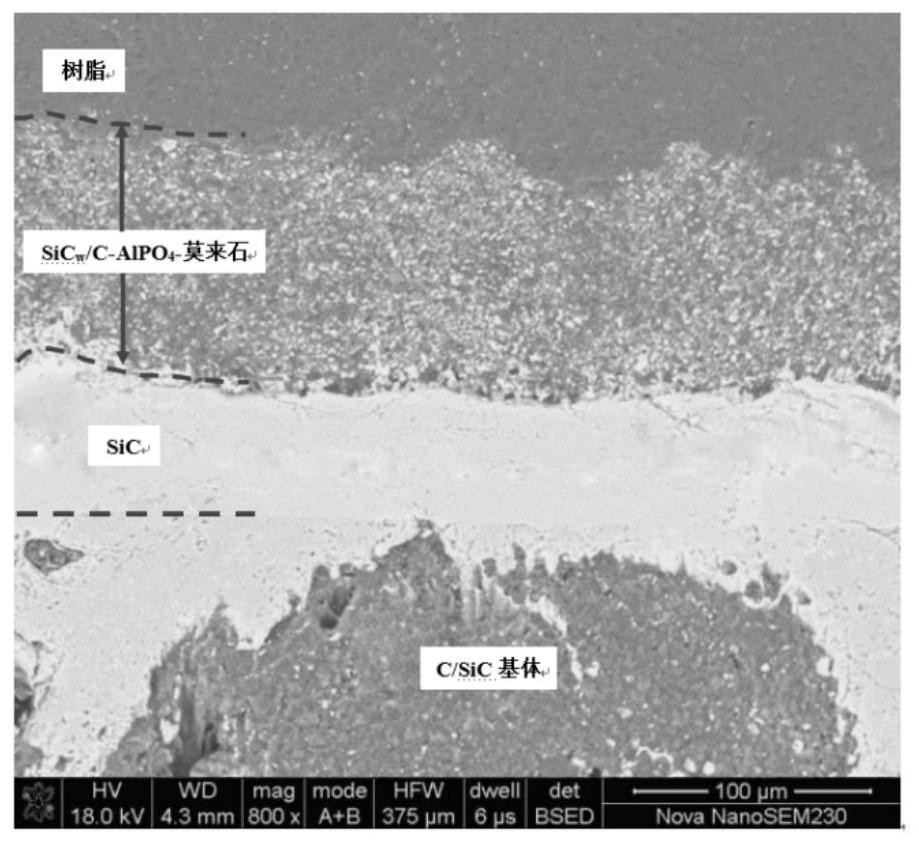

Environmental barrier coating as well as preparation method and application thereof

The invention provides an environmental barrier coating. The environmental barrier coating is composed of a SiC bonding layer, a mullite middle layer and an ytterbium silicate outer coating, which coat a C / SiC composite material and are sequentially arranged from inside to outside. The C / SiC composite material coated by a SiC coating is prepared by a secondary chemical vapor deposition (CVD) method; the mullite middle layer is prepared by combining a sol-gel method with an air spraying technology, and the ytterbium silicate outer coating is prepared by combining a solid phase sintering technology with an air spraying technology. Through a smart EBC coating system and a preparation process, the ytterbium silicate outer coating is prepared by combining a solid phase sintering technology withan air spraying technology for the first time, the mullite middle layer and the ytterbium silicate outer coating are tightly combined, and the coating is compact and free of cracks. The traditional sol-gel process is improved to a great extent, the defects of cracking, peeling and poor binding force in the sintering process of a coating prepared through a traditional sol-gel method are maximallyovercome, and the use requirements of large components and special-shaped parts can be met.

Owner:CENT SOUTH UNIV

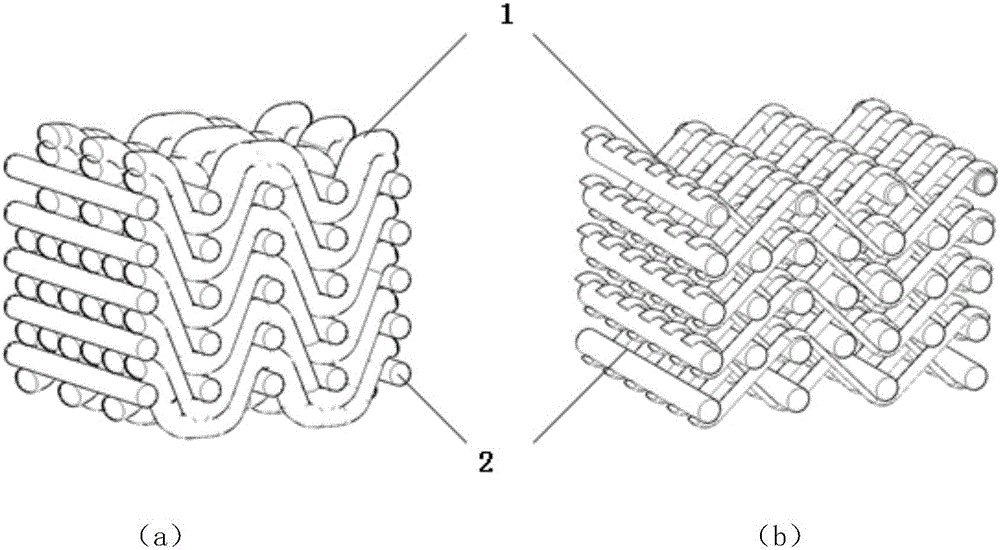

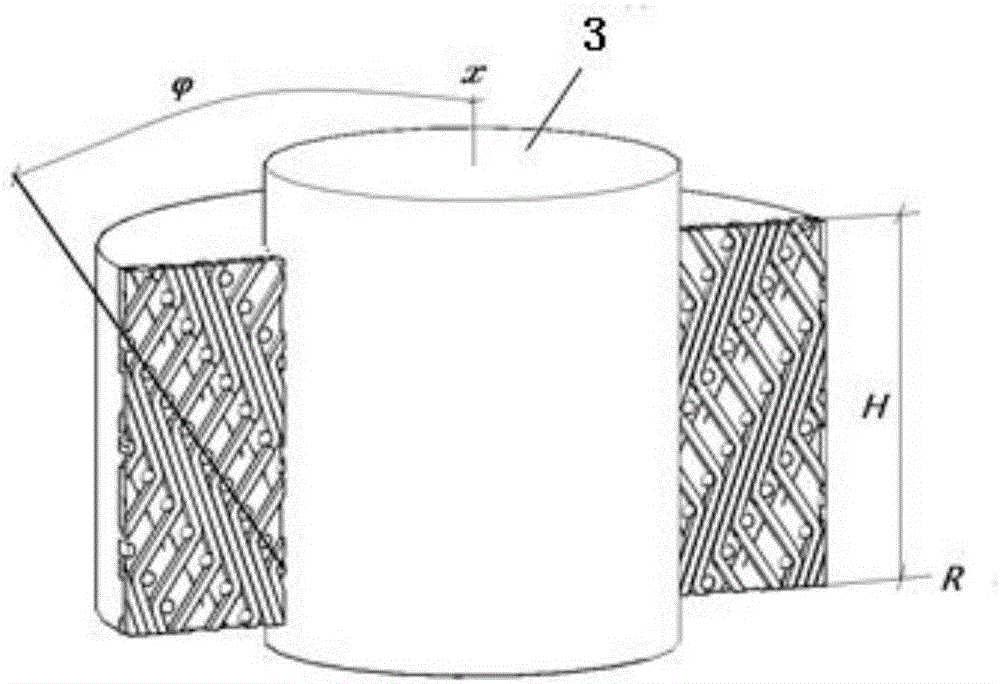

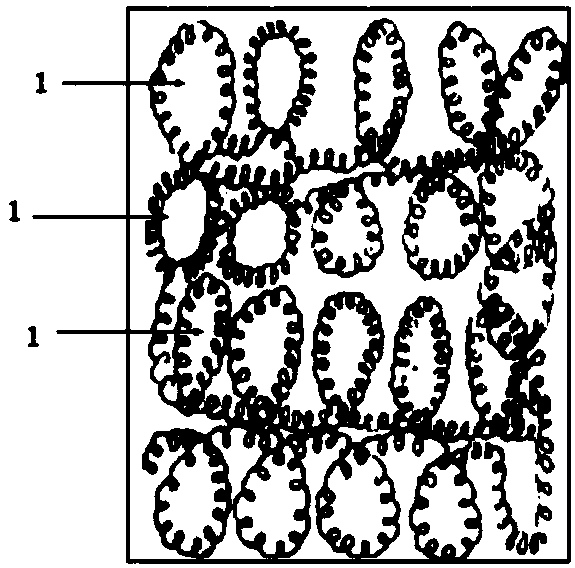

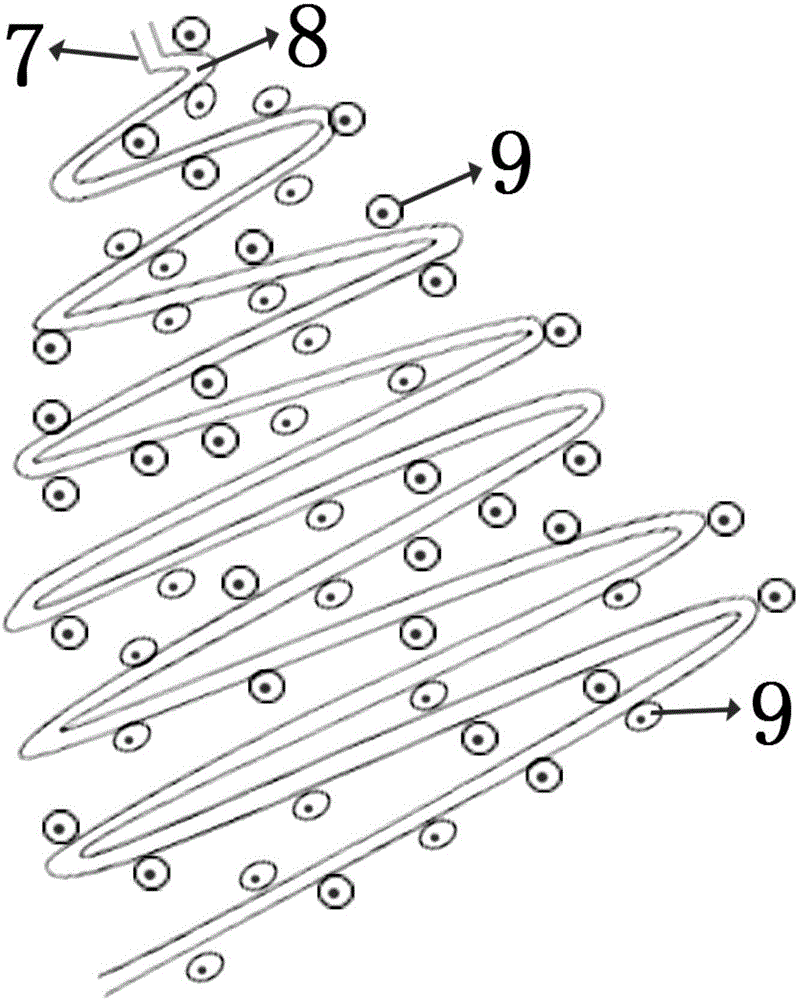

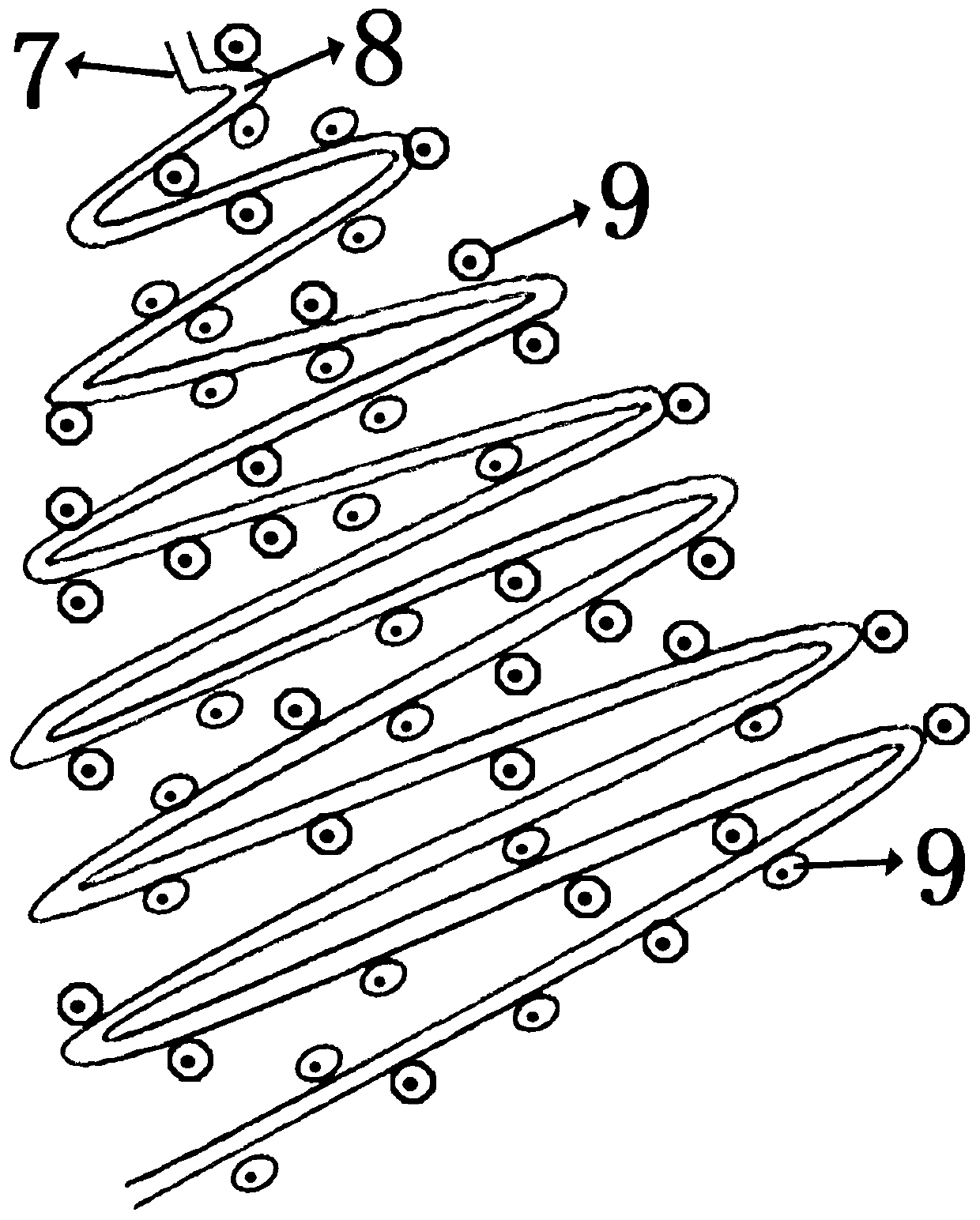

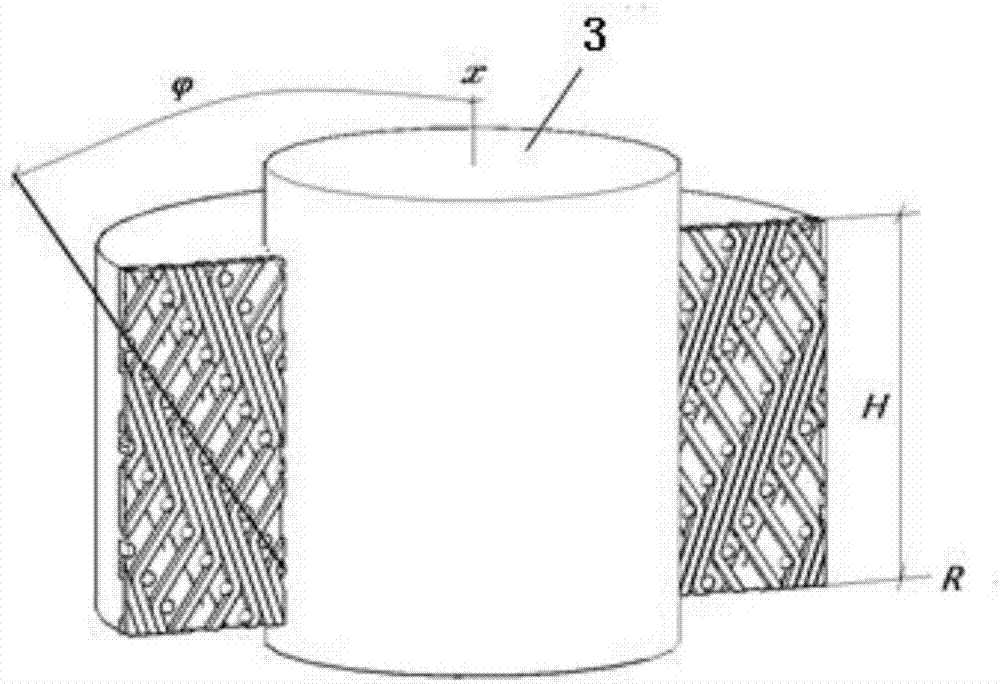

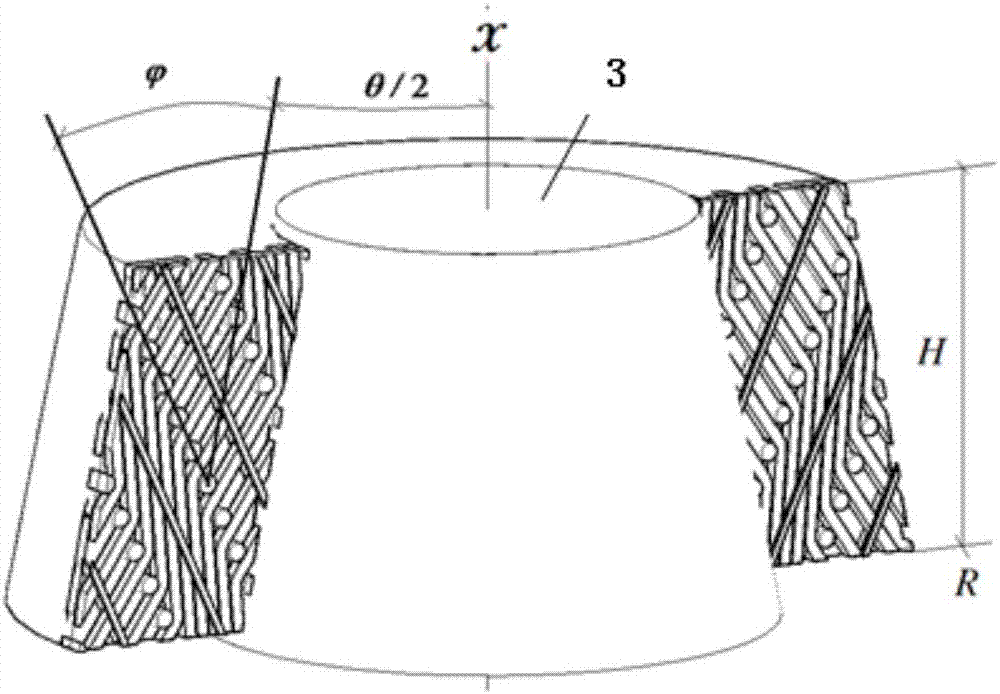

Metal rubber fabricated part and preparation thereof, and preparation method of metal rubber ring

PendingCN110345185AMeet preparationIncrease dampingElastic dampersShock absorbersPolymer scienceMetal rubber

The invention discloses a metal rubber fabricated part and a method thereof, and a preparation method of a metal rubber ring. The metal rubber fabricated part comprises a core body and a coating body,wherein the core body comprises a plurality of O-type weaving layers; each O-type weaving layer comprises a plurality of O-type structures formed by winding metal wires; the adjacent O-type structures of the adjacent layers incompletely coincide; the coating body coats the outer part of the core body, and comprises a plurality of first diagonal type weaving layers; each first diagonal type weaving layer is formed by winding metal wires in the same inclining direction; and the metal wires between the adjacent first diagonal type weaving layers form a first X-type structure. The metal rubber fabricated part is not filled with a die or a weaving process ruler, so that the preparation of the large metal rubber fabricated part is met. The invention also provides the preparation of the metal rubber ring. A metal rubber blank part is formed by winding the meal rubber fabricated part on a core shaft and weaving the metal rubber fabricated part, and is subjected to compression moulding to formthe metal rubber ring. Through the adoption of the method, layering and cracking of metal rubber can be avoided.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD

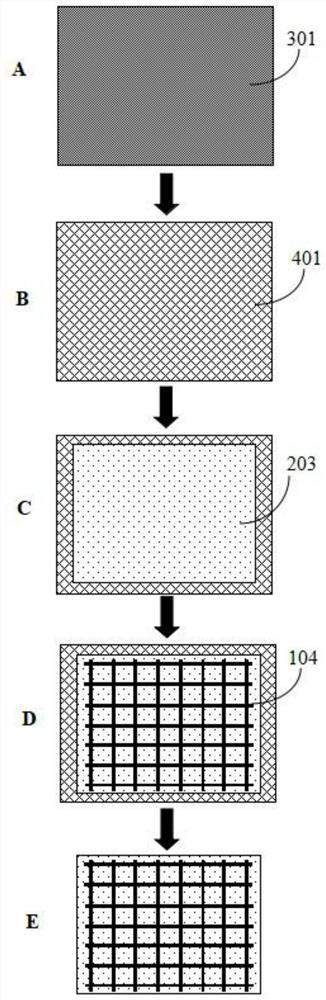

Preparation method of graphene transparent conductive film with superfine conductive pattern

InactiveCN112017807AImprove performanceIncrease the areaConductive layers on insulating-supportsSolid-state devicesParyleneThin membrane

The invention provides a preparation method of a graphene transparent conductive film with a superfine conductive pattern. The preparation method comprises the following steps of S1, preparing a planar glass substrate, S2, preparing a parylene (parylene) film on the surface of the planar glass substrate to serve as a release layer of the conductive film, S3, preparing a layer of polyimide (PI) film on the surface of the parylene film, S4, preparing graphene on the surface of the transparent insulating film and forming a graphene fine pattern by adopting a laser-induced graphene (LIG) technology of a short-wavelength laser light source, and S5, stripping the polyimide transparent insulating film from the surface of the planar glass to obtain the superfine flexible graphene transparent conductive film.

Owner:安徽宇航派蒙健康科技股份有限公司

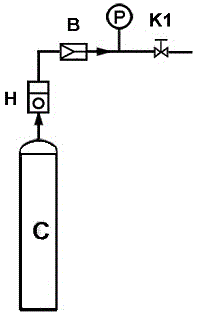

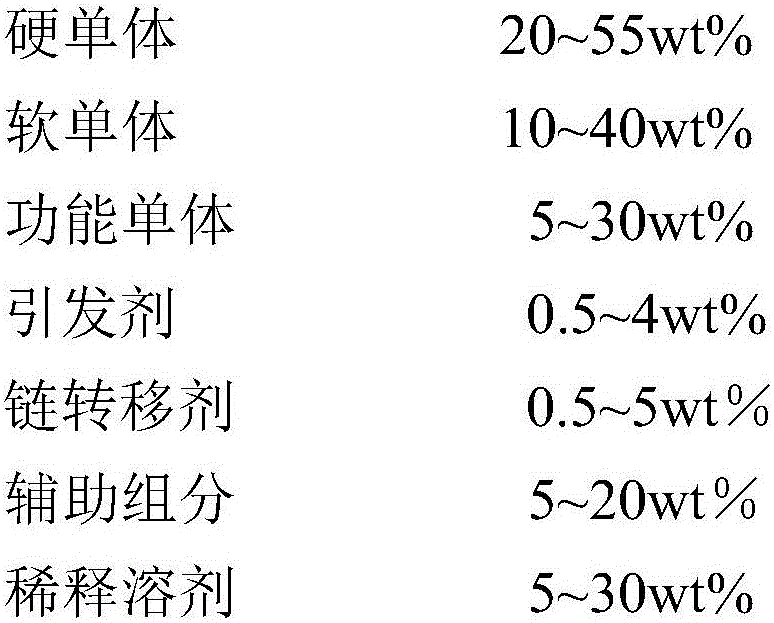

Device for preparing ultrafine particles using supercritical fluid

InactiveCN103521128BPreparation to meetLarge adjustment rangeSolution crystallizationMaterial granulationRapid expansionSupercritical fluid extraction

The invention discloses a device for preparing ultrafine particles by using supercritical fluid. By selecting and controlling the opening and closing of a series of auxiliary valves in the equipment assembly, a series of device units for preparing ultrafine particles by using supercritical fluid are formed. The assembly can realize five functions including supercritical fluid extraction technology, supercritical anti-solvent particle preparation technology, supercritical solution rapid expansion particle preparation technology, supercritical fluid enhanced solution diffusion technology, supercritical fluid assisted microencapsulation technology, etc. It can meet the requirements of material extraction, preparation of organic micro / nano materials, and preparation of inorganic micro / nano materials. The equipment has the advantages of easy operation, wide adjustable range of equipment experimental parameters, strong stability, and high production efficiency. It has great application potential in the field of material preparation and is extremely suitable for experimental research in universities and research institutes, as well as small tests in factories. It is required for proofing and saves a lot of equipment purchase expenses for users.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

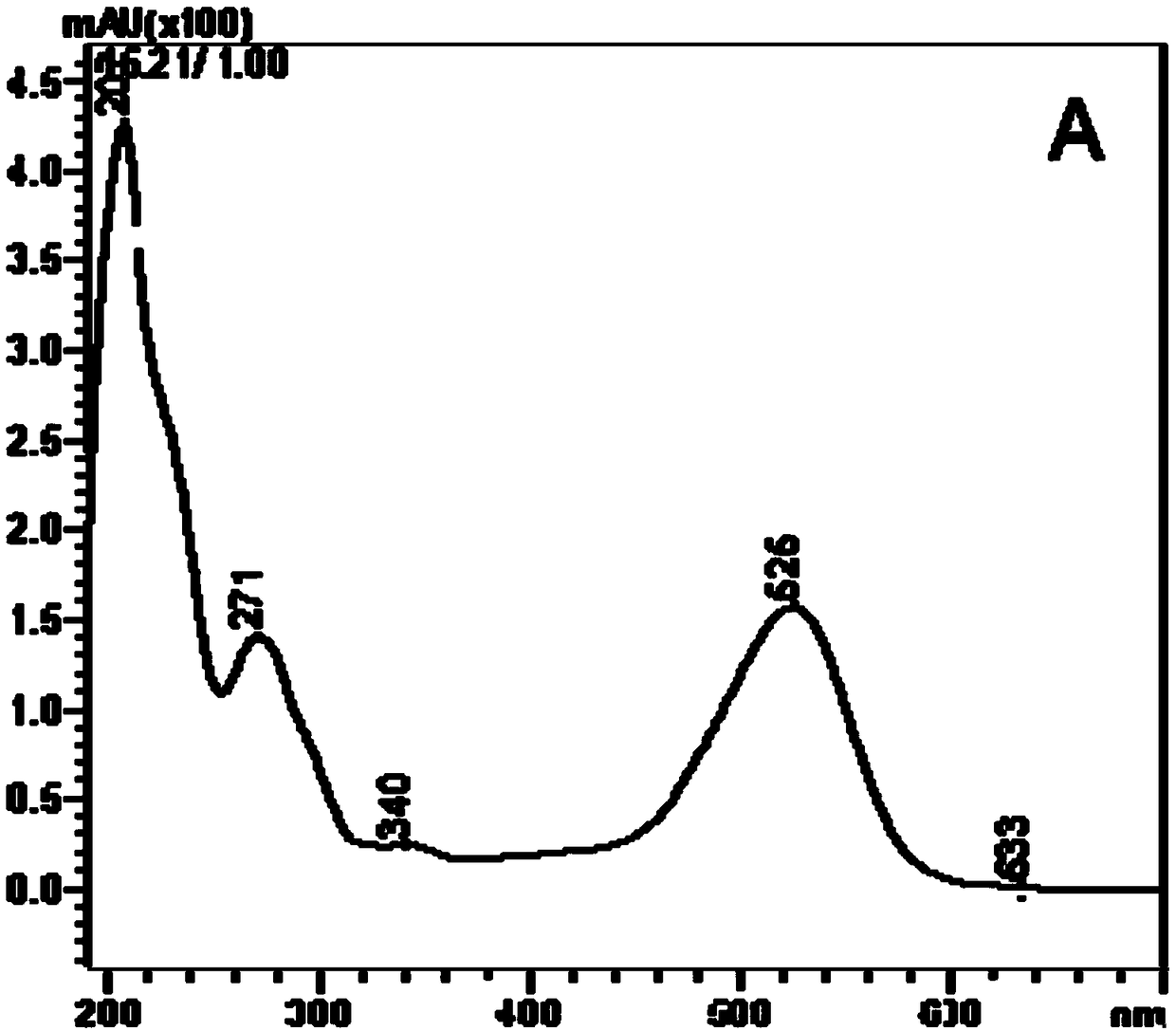

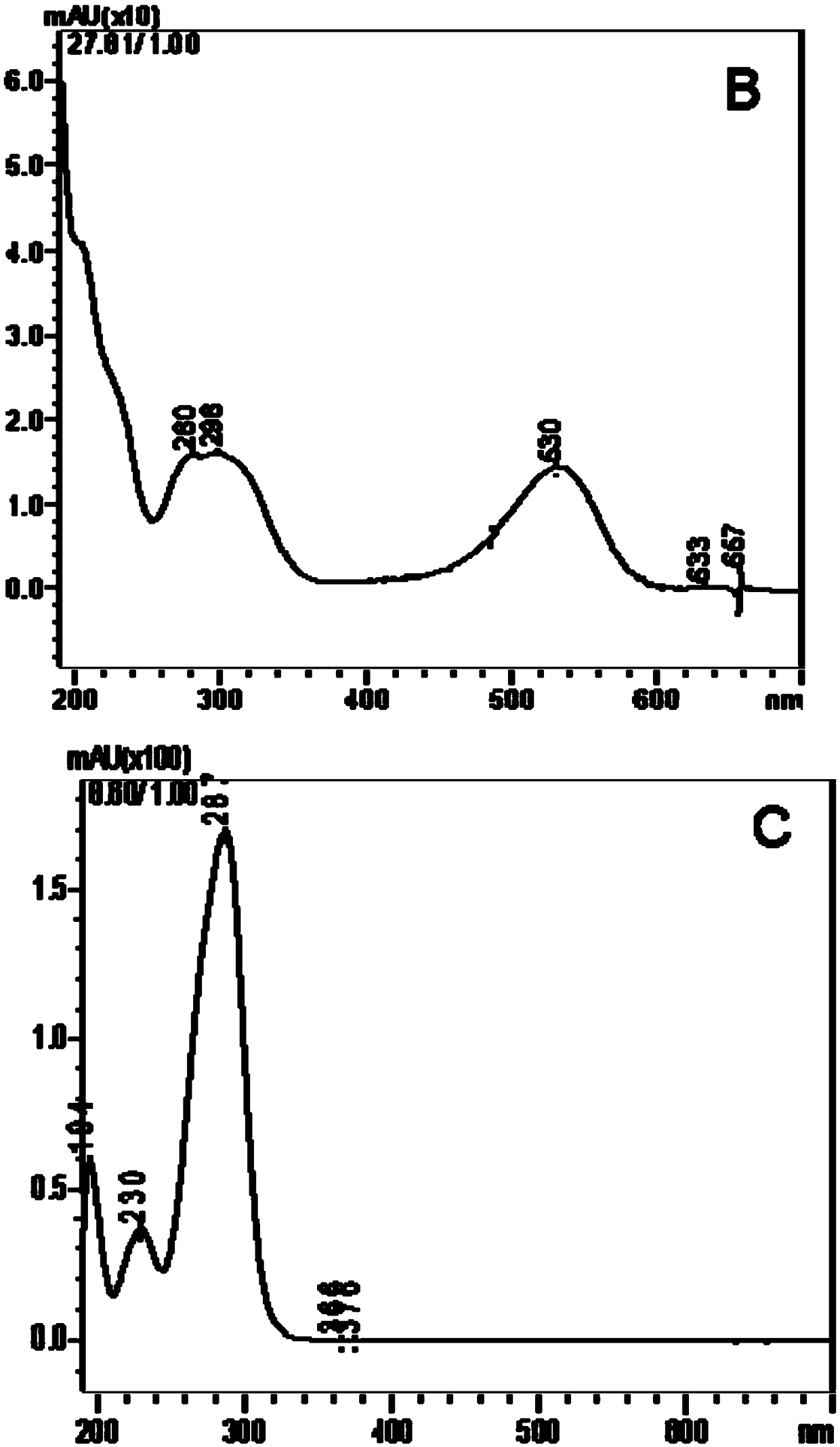

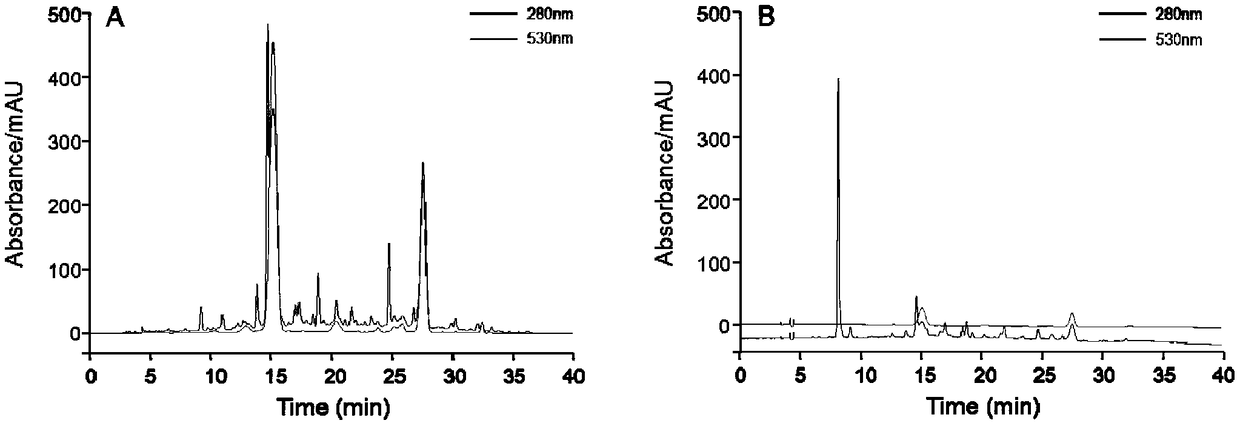

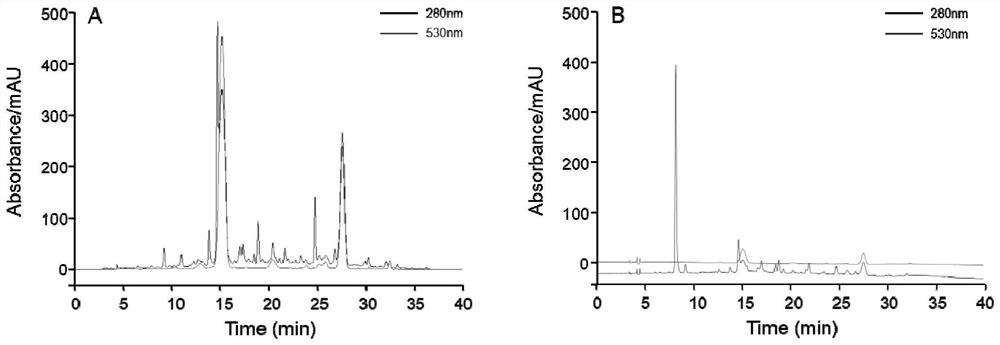

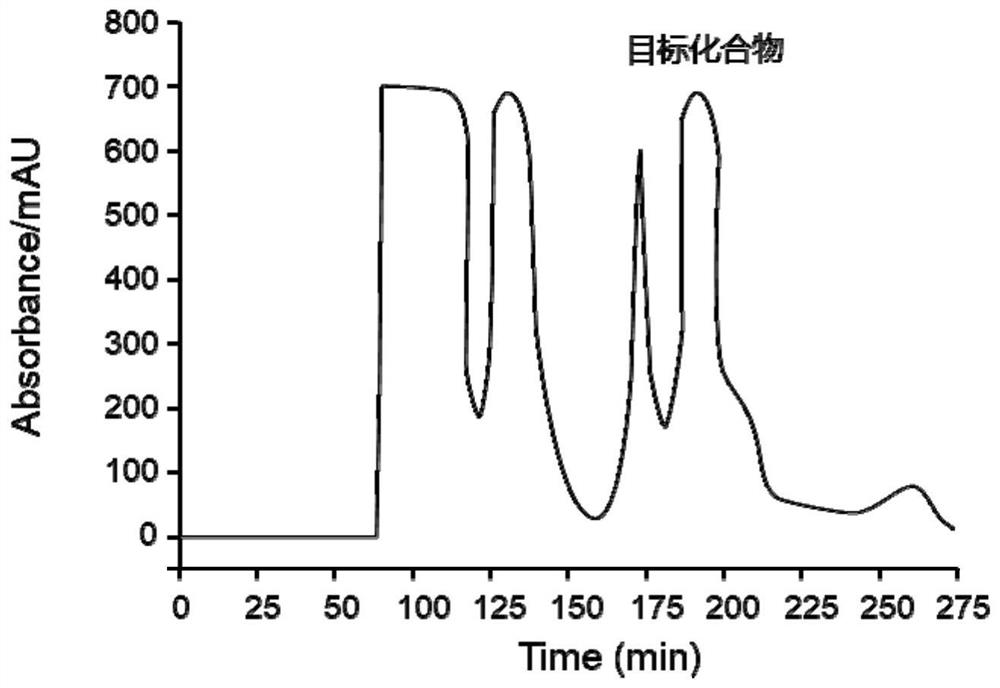

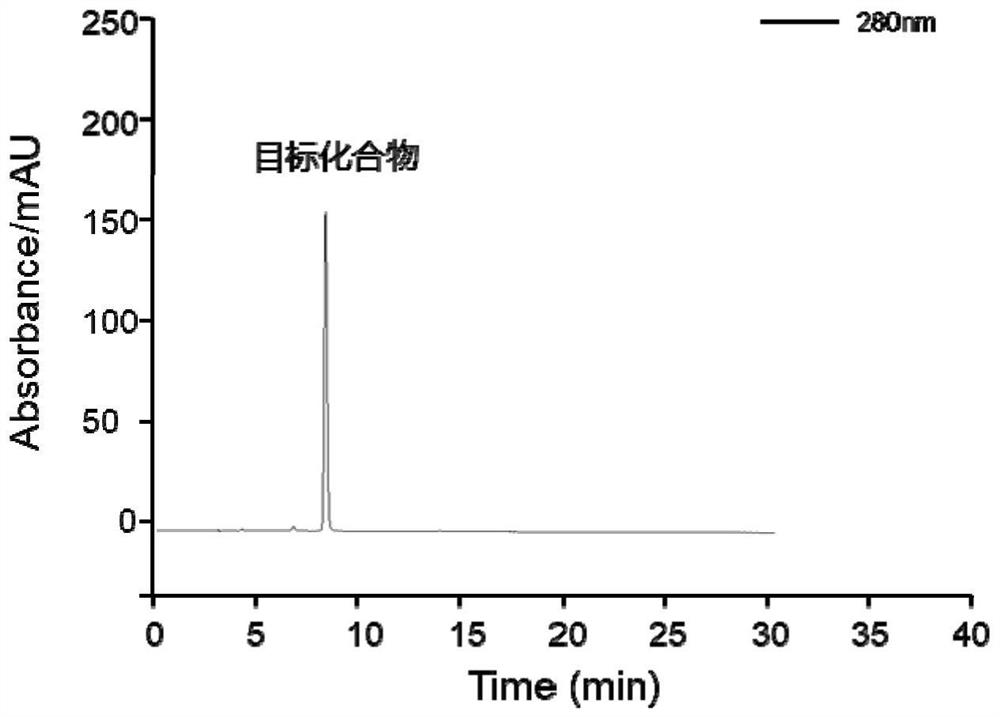

Method for preparing caftaric acid standard product from vitis davidii juice

ActiveCN109020815APreparation to meetLarge amount of preparationOrganic compound preparationCarboxylic acid esters separation/purificationChromatographic separationFreeze-drying

The invention discloses a method for separating and preparing a caftaric acid standard product in a vitis davidii juice by using high-speed countercurrent chromatography. The method comprises the following steps: enriching the vitis davidii juice by using macroporous adsorption resin, eluting the material with ethanol, performing freeze-drying to obtain a crude sample, and performing high-speed countercurrent separation on the crude sample through solvent system water. The invention establishes the method for separating a polyphenol monomer in the vitis davidii juice by the high-speed countercurrent chromatography, and the method identifies the seperated monomer as caftaric acid by the methods such as HPLC-MS and nuclear magnetic resonance. The caftaric acid has an important pharmacological function, and its standard product is expensive, and the caftaric acid prepared by the method of the present invention has a purity of 95.8% and a calculated yield of 61.99 mg / L. The method of the high-purity standard product prepared can satisfy the large-scale preparation of caftaric acid of vitis davidii.

Owner:HUNAN AGRICULTURAL UNIV

Preparation method of quantum dot, quantum dot/UV glue solution and quantum dot doped optical fiber

ActiveCN110408391AAchieving controllable synthesisGood dispersionMaterial nanotechnologyTin compoundsThermal decomposition methodQuantum dot

The invention discloses a preparation method of a quantum dot, a quantum dot / UV glue solution and a quantum dot doped optical fiber, and belongs to the technical field of nano materials and optical communication. According to the preparation method of a quantum dot, the Cu2ZnSnS4 quantum dot is prepared by a thermal decomposition method, and the controllable synthesis of quantum dot structure andsize can be realized, and the product has high dispersibility and uniformity and has few impurity phases. The technical problem that the pure-phase Cu2ZnSnS4 quantum dot is difficult to synthesize issolved, the quantum dot obtained can be directly used for preparing the quantum dot doped optical fiber, and great industrial value is achieved.

Owner:ZHONGTIAN TECH FIBER OPTICS +2

Blood capillary network and making method thereof

ActiveCN106620877AImprove securityOvercoming important barriers to clinical entryFilament/thread formingProsthesisCapillary networkLiver and kidney

The invention provides a blood capillary network and a making method thereof. A soluble three-dimensional spinning network is made by adopting a centrifugal spinning method, animal cells are cultured on the soluble three-dimensional spinning network and grow and proliferate along the soluble three-dimensional spinning network, and the blood capillary network is obtained after the soluble three-dimensional spinning network is completely dissolved. A high-voltage electrostatic field and a large number of molds are not needed, a centrifugal force is only utilized as the power for producing the soluble three-dimensional spinning network, the production yield is greatly improved, the energy consumption cost is greatly reduced, the safety of production operation is improved, the demand for large-scale production of the three-dimensional spinning network of engineering-oriented tissues is met, and the important clinical obstacle of tissue engineering structures are also overcome. The blood capillary network is low in preparation cost, and required three-dimensional blood capillary networks can be provided for establishment of full and effective blood capillary network systems of thick engineering-oriented tissues or organs such as the liver and kidney.

Owner:叶川 +5

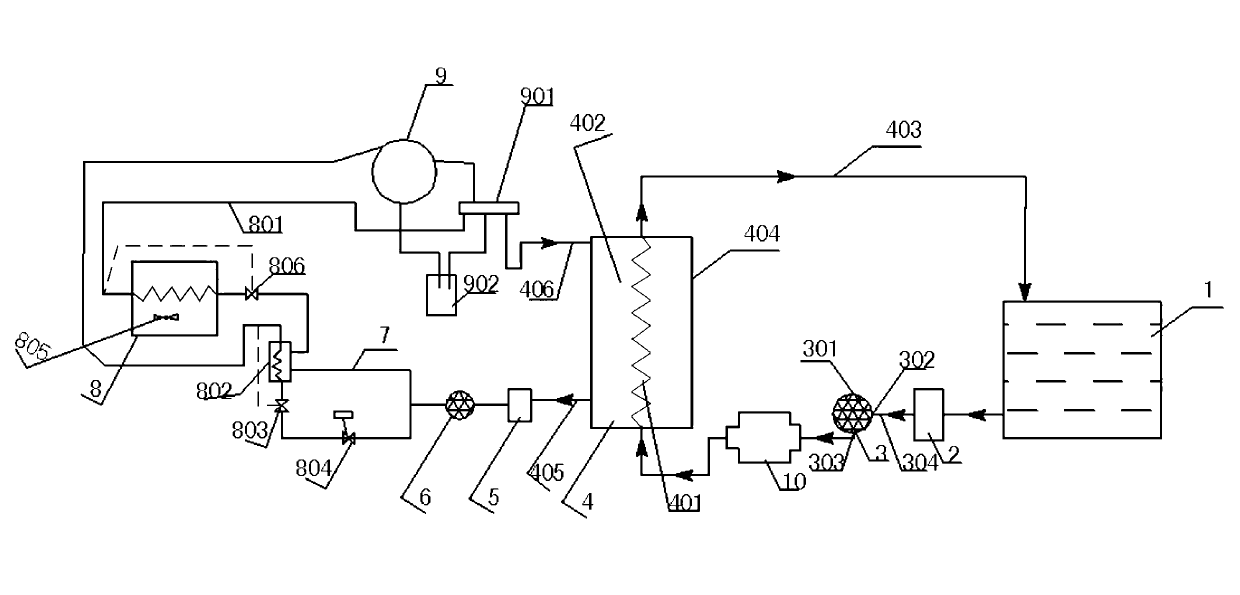

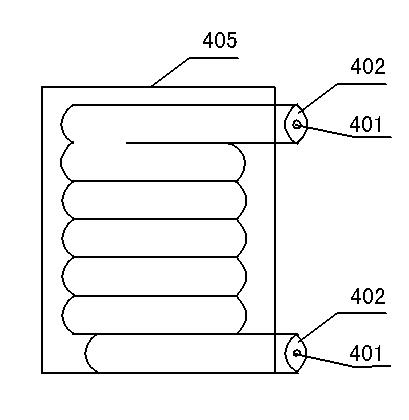

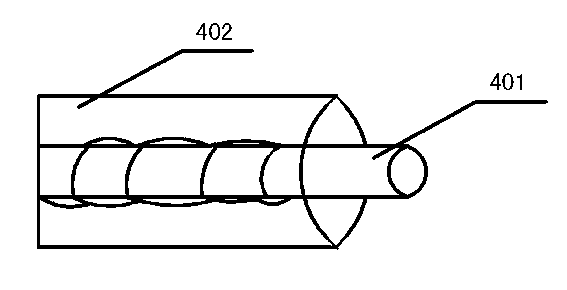

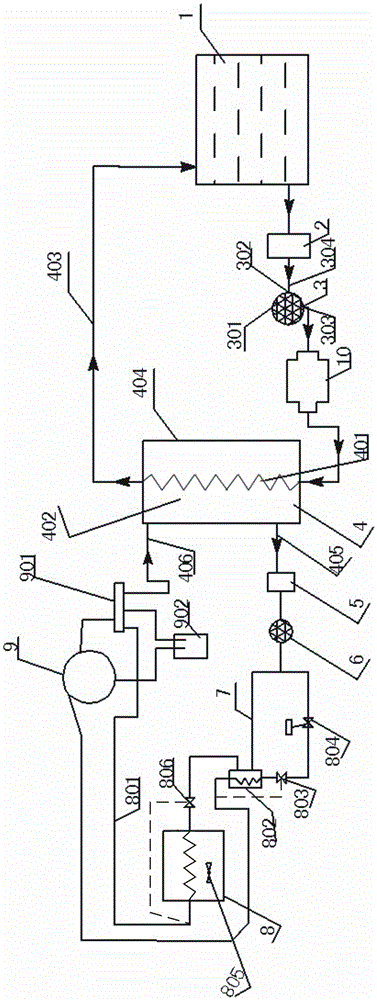

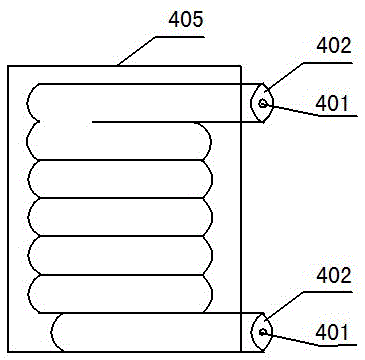

Preparation method for industrial high-temperature hot water

ActiveCN103307744AThe production is largePreparation to meetFluid heatersManufacturing cost reductionWater use

The invention provides a preparation method for industrial high-temperature hot water. A hot water exchange circulation system, an air exchange heating circulation system and a high-temperature water heating pool for cleaning workpieces together achieve circulatory heating of high-temperature hot water, so that preparation of high-temperature hot water used for cleaning machine components in the machine manufacturing industry, the bearing manufacturing industry and other processing procedures is realized to solve the irresolvable technical problems existing in conventional steam boiler heating and electrical heating, energy saving and environmental protection are achieved, the manufacturing cost is lowered and the production quality and the environmental quality are improved.

Owner:DONGGUAN HOTWHEELS ENERGY TECH

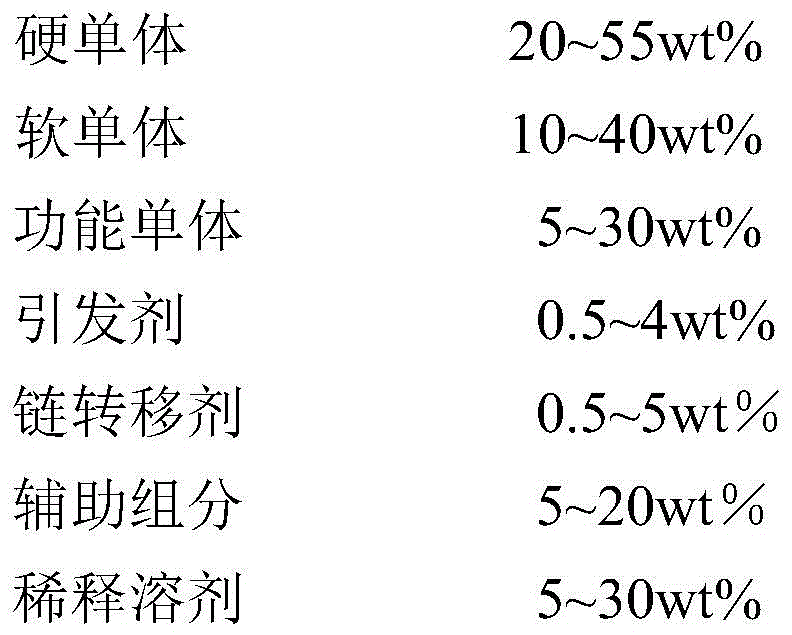

A kind of preparation method of solid acrylic resin

The invention relates to a preparation method of an acrylic resin used in the paint and printing ink industry, in particular to a preparation method of a solid acrylic resin. Add hard monomers, soft monomers, functional monomers, initiators, chain transfer agents and auxiliary components into the reactor for polymerization; when the total conversion rate of the above-mentioned monomers in the reactor is 40-50% When starting to drop the diluted solvent into the reactor gradually to reduce the viscosity until the total conversion rate of the above-mentioned monomers reaches 70-80%, the resulting dilution is discharged from the reactor into the storage tank; then The dilution is continuously poured into the tubular reactor from the storage tank to carry out the polymerization reaction; the reaction product enters the devolatilization tower after coming out of the tubular reactor, and the solid acrylic resin after removing the diluted solvent is discharged from the devolatilization tower. The lower portion was discharged to obtain a solid acrylic resin. The invention overcomes the disadvantages that bulk polymerization is easy to produce detonation phenomenon and the polymerization temperature is difficult to control, and improves the utilization efficiency of equipment.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Pig fermented feed and preparation method thereof

InactiveCN110200159AOptimized formulaEfficient production processFood processingAnimal feeding stuffDiseaseLean meat

The invention discloses a pig fermented feed and a preparation method thereof. The pig fermented feed comprises the following components in parts by mass: 30-50 parts of broussonetia papyrifera leaves, 10-30 parts of cake dregs, 8-12 parts of corn, 3-7 parts of green bran, 3-7 parts of wheat middling, 10-20 parts of wheat bran and a EM bacteria solution leavening agent. The sum of water in the EMbacteria solution leavening agent and water in the broussonetia papyrifera leaves accounts for 25%-35% of the total weight of the raw materials, the total part of the broussonetia papyrifera leaves and the cake dregs is 60 parts by mass, and the mass concentration of the EM bacteria solution leavening agent is 1%-10%. Pigs fed by the pig fermented feed disclosed by the invention are fast in growth, strong in disease resistance, short in feeding period and high in growth speed, and also have the characteristics of high slaughter rate and high lean meat rate.

Owner:江苏黑钻生物科技有限公司

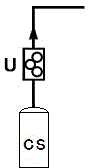

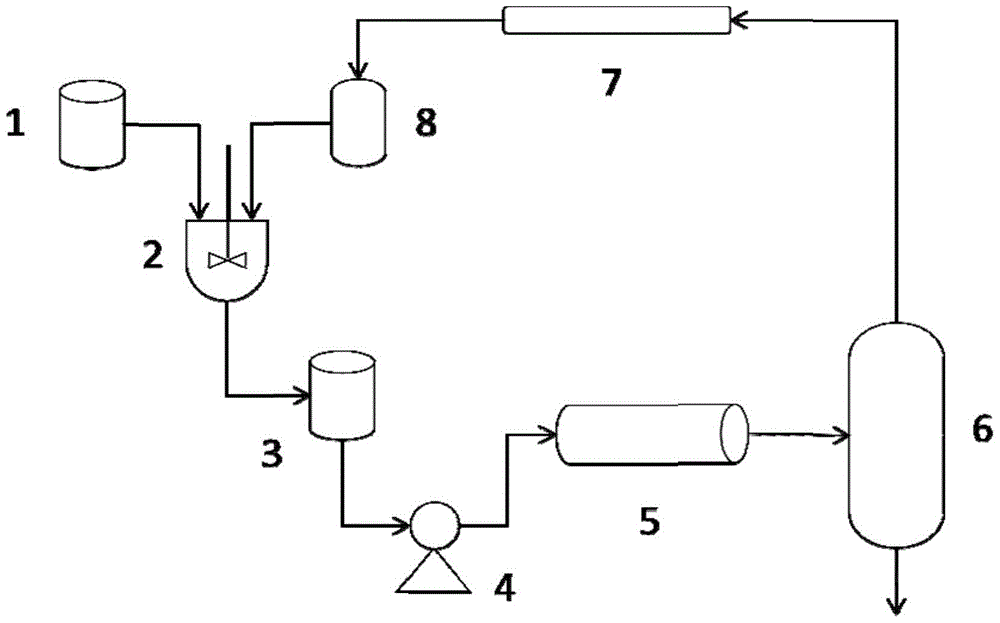

Apparatus and method for preparing nanomaterials by supercritical-solvothermal combination

InactiveCN103623746BPreparation to meetSimple and fast operationMaterial nanotechnologyPressure vessels for chemical processCarbon dioxide cylinderEngineering

The invention discloses a supercritical-solvent heat combined device and a method for preparing a nanometer material. The device comprises a carbon dioxide steel bottle, a carbon dioxide cooler, a carbon dioxide pump, an entrainer accommodator, an entrainer pump, a first valve, a second valve, a third valve, a secondary reactor, a fourth valve, a main reactor, a fifth valve and a separator. The device can realize a plurality of supercritical-solvent heat combined preparation methods, and can satisfy the preparation of the nanometer material and the demands of controlling such crystal growth behaviors as crystal transfer, grain size and morphology evolution of an inorganic nanometer material through splicing pipelines and modules and adjusting such conditions or parameters as valve switch combinations, raw material placing mode and entrainer entering mode. The device has such advantages as simplicity and convenience for operation, wide adjusting range of experimental parameters, strong stability and high productivity, has huge application potential in the research, preparation and application fields of the nanometer material, and has wider industrialization foreground.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

High-strength high-plasticity heat-resistant magnesium alloy component and preparation method thereof

The invention provides a high-strength high-plasticity heat-resistant magnesium alloy component and a preparation method thereof, the high-strength high-plasticity heat-resistant magnesium alloy component comprises the following components: 5.0-9.0% of Gd, 2.0-6.0% of Y, 0.1-0.5% of Zn, 0.3-1.0% of Zr, and the balance of Mg and inevitable impurities, and the sum of the mass percent of rare earth elements Gd and Y in the component composition is 8-12%; the preparation method comprises the steps of alloy smelting, homogenization treatment, strong plastic deformation, hot forming and warm deformation, specifically, an obtained formed part is heated at the temperature of 200-250 DEG C, heat preservation is conducted for 2 h, then the formed part is put into a mold preheated at the temperature of 200 DEG C, the deformation amount is controlled to be 3-10%, and heat treatment is conducted. The prepared magnesium alloy component is fine in grain, the tensile strength at the room temperature is larger than or equal to 428 MPa, the percentage elongation after fracture is larger than or equal to 12%, the tensile strength at the temperature of 200 DEG C is larger than or equal to 358 MPa, the percentage elongation after fracture is larger than or equal to 13%, the magnesium alloy component can widely replace 2A12 and other medium-strength aluminum alloys, and the application range of the magnesium alloy can be further expanded.

Owner:中国兵器装备集团西南技术工程研究所

A sic whisker with c-alpo 4 Preparation method of powder synergistically modified mullite coating

Owner:CENT SOUTH UNIV

A kind of method of preparing caffeoyl tartaric acid standard substance from thorn grape juice

ActiveCN109020815BPreparation to meetLarge amount of preparationOrganic compound preparationCarboxylic acid esters separation/purificationBiotechnologyChromatographic separation

The invention discloses a method for separating and preparing a caftaric acid standard product in a vitis davidii juice by using high-speed countercurrent chromatography. The method comprises the following steps: enriching the vitis davidii juice by using macroporous adsorption resin, eluting the material with ethanol, performing freeze-drying to obtain a crude sample, and performing high-speed countercurrent separation on the crude sample through solvent system water. The invention establishes the method for separating a polyphenol monomer in the vitis davidii juice by the high-speed countercurrent chromatography, and the method identifies the seperated monomer as caftaric acid by the methods such as HPLC-MS and nuclear magnetic resonance. The caftaric acid has an important pharmacological function, and its standard product is expensive, and the caftaric acid prepared by the method of the present invention has a purity of 95.8% and a calculated yield of 61.99 mg / L. The method of the high-purity standard product prepared can satisfy the large-scale preparation of caftaric acid of vitis davidii.

Owner:HUNAN AGRICULTURAL UNIV

Preparation method of high temperature hot water for industrial use

ActiveCN103307744BThe production is largePreparation to meetFluid heatersWater useManufacturing cost reduction

The invention provides a preparation method for industrial high-temperature hot water. A hot water exchange circulation system, an air exchange heating circulation system and a high-temperature water heating pool for cleaning workpieces together achieve circulatory heating of high-temperature hot water, so that preparation of high-temperature hot water used for cleaning machine components in the machine manufacturing industry, the bearing manufacturing industry and other processing procedures is realized to solve the irresolvable technical problems existing in conventional steam boiler heating and electrical heating, energy saving and environmental protection are achieved, the manufacturing cost is lowered and the production quality and the environmental quality are improved.

Owner:DONGGUAN HOTWHEELS ENERGY TECH

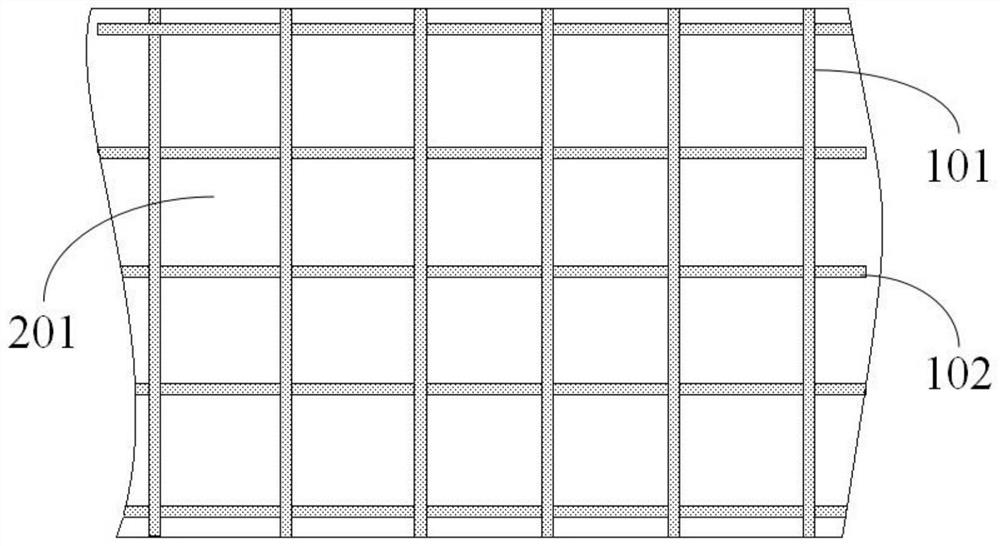

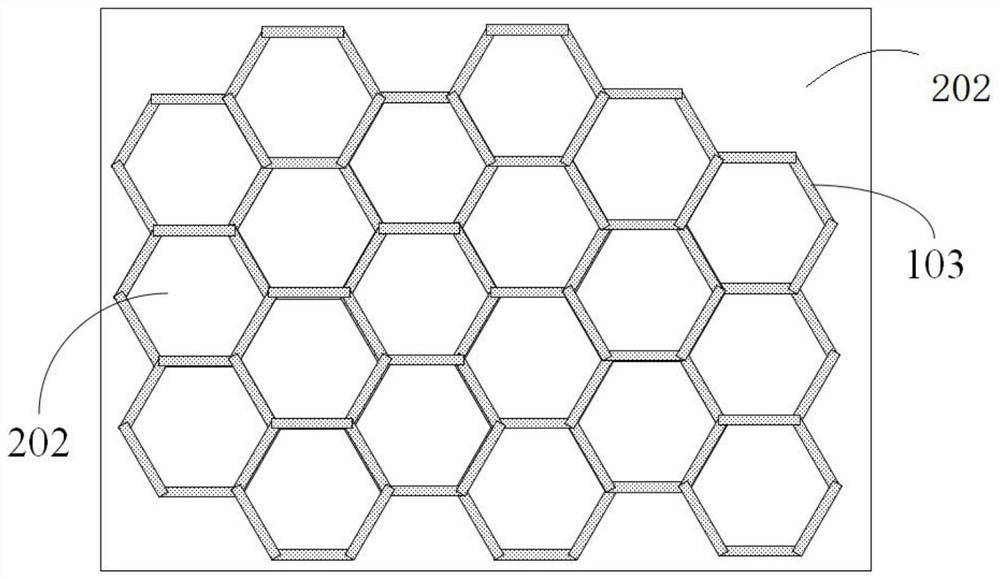

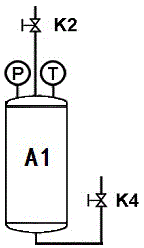

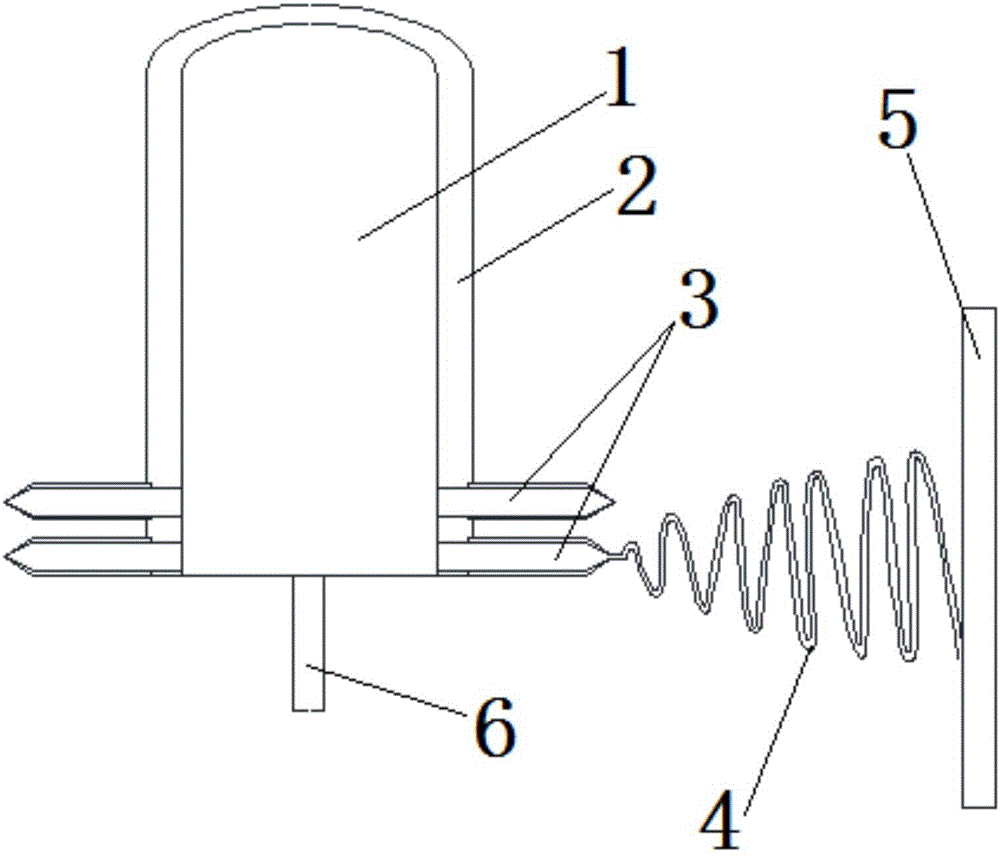

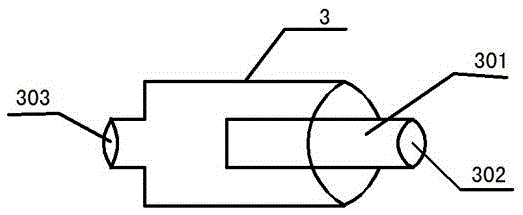

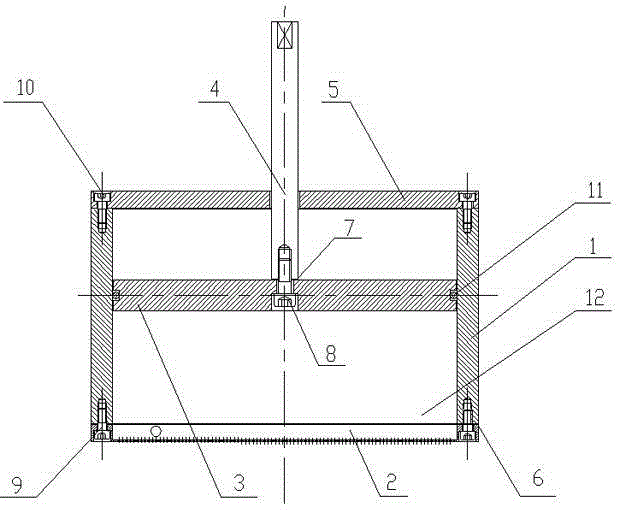

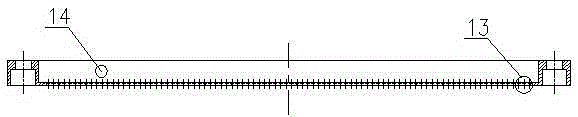

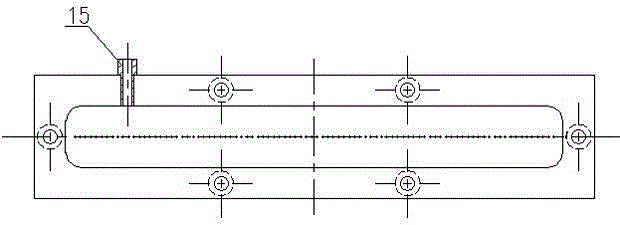

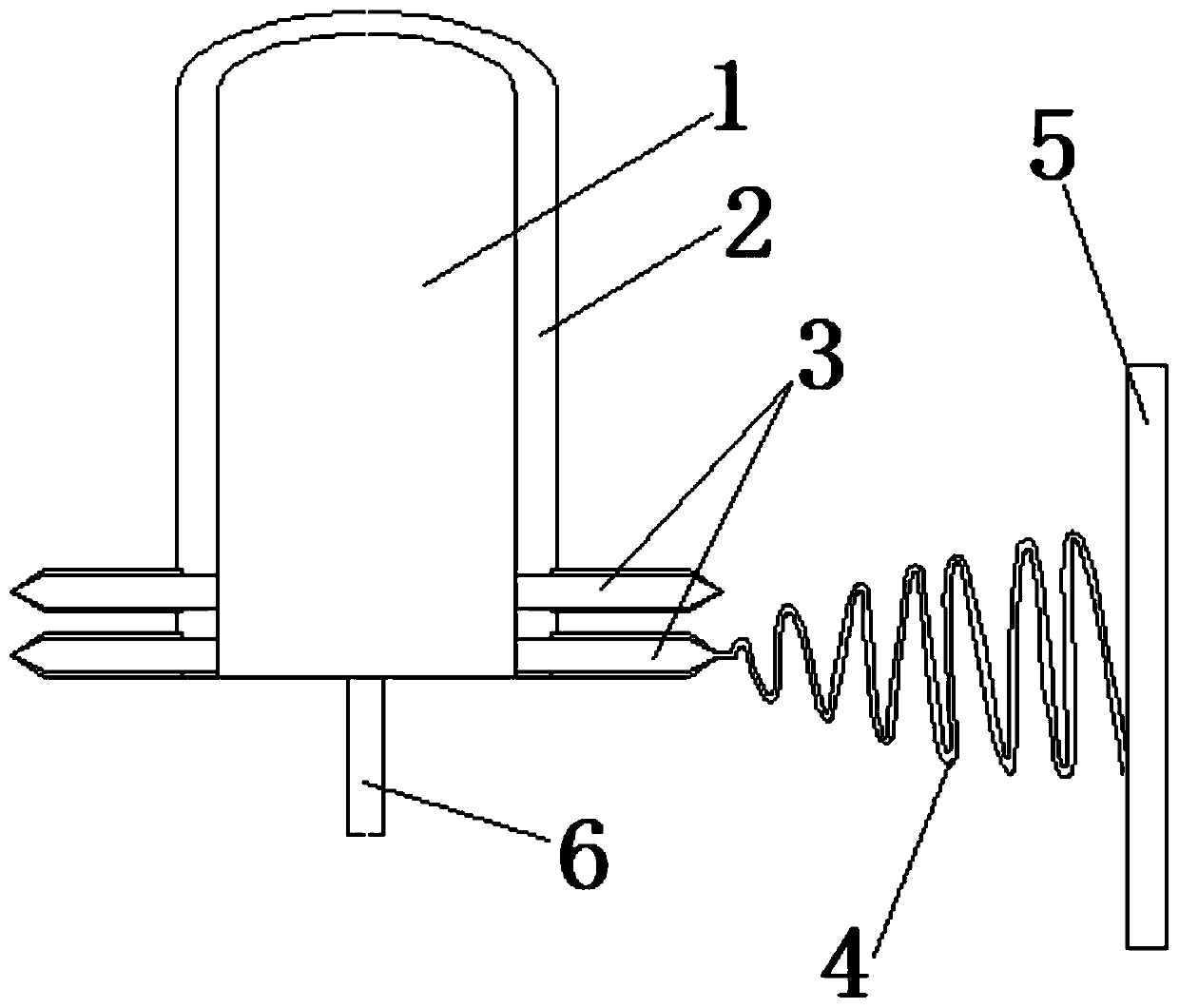

A device for preparing ultra-fine auxiliary gates by extrusion for crystalline silicon cells

InactiveCN103824897BPreparation to meetIncrease productivityFinal product manufacturePhotovoltaic energy generationInterference fitEngineering

The invention discloses a crystalline silicon cell extrusion type ultrafine auxiliary grid preparation device. The objective of the invention is to solve the problems of difficulty in height-width ratio control, silver slurry waste and high scrap rate in screen printing. The crystalline silicon cell extrusion type ultrafine auxiliary grid preparation device comprises a vertically-arranged sprayer cylinder body, a sprayer mounted at the lower end of the sprayer cylinder body, and a sprayer end cover mounted at the upper end of the sprayer cylinder body; a piston is arranged inside the sprayer cylinder body; a piston rod fixed on the upper end of the piston penetrates the sprayer end cover; the piston is in interference fit with the sprayer cylinder body; a plurality of nozzles are formed in the sprayer; and the diameter of the spraying opening of each nozzle is in a range of 20 micron to 30 micron. With the crystalline silicon cell extrusion type ultrafine auxiliary grid preparation device of the invention adopted, n auxiliary grids can be prepared at a time, wherein the n=1, 2, 3..., and therefore, photoelectric conversion efficiency can be improved, and cost can be reduced, and problems existing in maintenance and scale production can be solved, and a foundation can be laid for full automation of solar cell sheet production lines. The crystalline silicon cell extrusion type ultrafine auxiliary grid preparation device can adapt to the development direction of thinning in the future.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

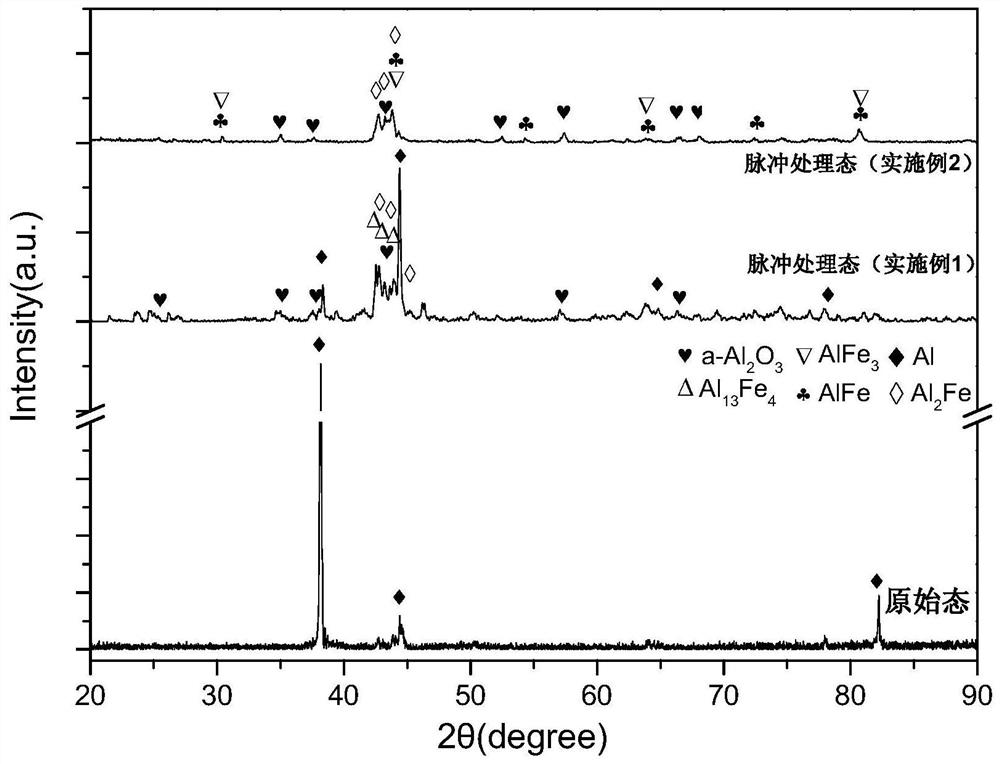

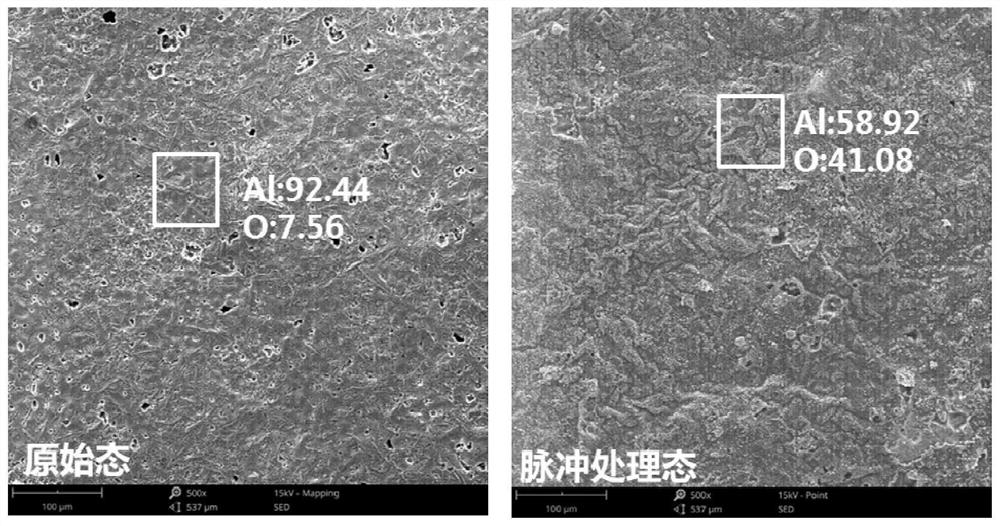

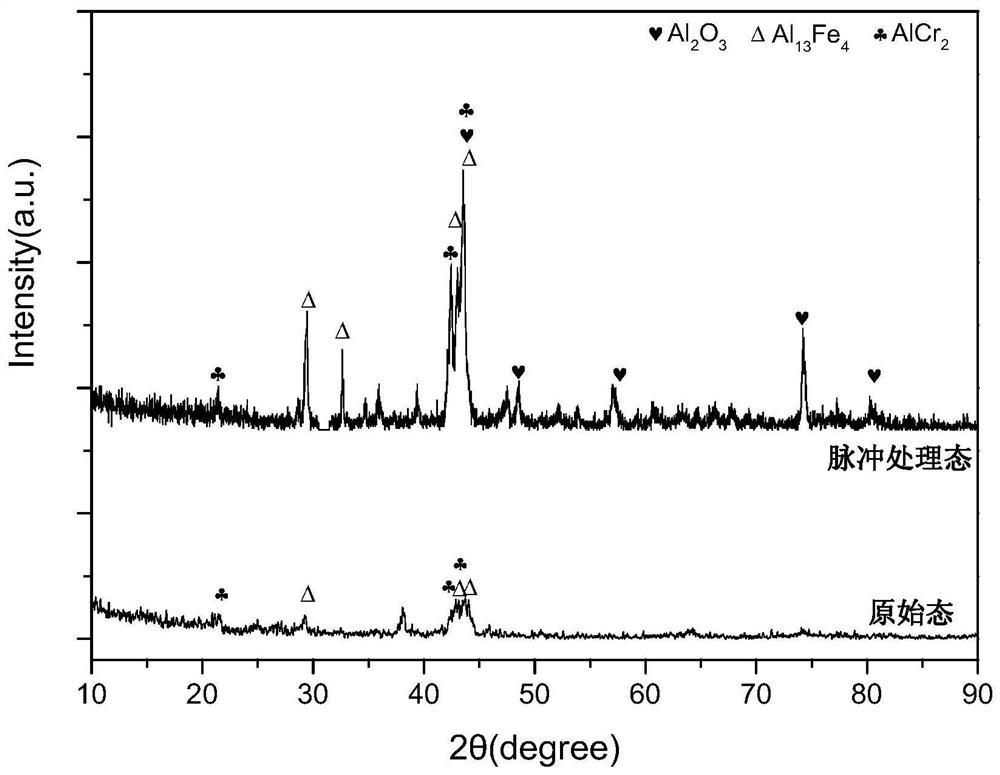

A method for rapidly preparing aluminum oxide on the surface of 316l stainless steel aluminide anti-tritium coating

ActiveCN113265609BOvercome the problem of significant performance degradationImprove efficiencyHot-dipping/immersion processesSolid state diffusion coatingSurface oxidationAluminide

The invention discloses a method for quickly preparing aluminum oxide on the surface of a 316L stainless steel aluminide tritium-resistance coating, which belongs to the technical field of coatings. The method is to connect the 316L stainless steel with aluminide tritium-resistant coating to the pulse power supply with a wire, and continue to apply the pulse current until the corresponding time, and select the appropriate pulse current processing parameter range according to the type of sample tritium-resistant coating and the size of the pulse-treated sample: frequency 500Hz~33000Hz, pulse width 1μs~100ms, current density 2A / mm 2 ~50A / mm 2 , the action time is 1min to 8h, and the Joule heat temperature rise caused by the electric pulse is 300-1200℃. Compared with the existing method of preparing a tritium-blocking oxide layer using a traditional high-temperature thermal oxidation aluminum oxide tritium-blocking coating, the present invention can realize the formation of an oxide layer on the coating surface at a lower processing temperature, and the processing required The time is short, it can meet the processing of workpieces of various sizes and shapes, the operation process is simple, and the energy consumption is low, which meets the requirements of the current industrial green development plan.

Owner:UNIV OF SCI & TECH BEIJING

A kind of capillary network and its preparation method

ActiveCN106620877BPreparation to meetWide adaptabilityFilament/thread formingProsthesisCapillary networkLiver and kidney

The invention provides a blood capillary network and a making method thereof. A soluble three-dimensional spinning network is made by adopting a centrifugal spinning method, animal cells are cultured on the soluble three-dimensional spinning network and grow and proliferate along the soluble three-dimensional spinning network, and the blood capillary network is obtained after the soluble three-dimensional spinning network is completely dissolved. A high-voltage electrostatic field and a large number of molds are not needed, a centrifugal force is only utilized as the power for producing the soluble three-dimensional spinning network, the production yield is greatly improved, the energy consumption cost is greatly reduced, the safety of production operation is improved, the demand for large-scale production of the three-dimensional spinning network of engineering-oriented tissues is met, and the important clinical obstacle of tissue engineering structures are also overcome. The blood capillary network is low in preparation cost, and required three-dimensional blood capillary networks can be provided for establishment of full and effective blood capillary network systems of thick engineering-oriented tissues or organs such as the liver and kidney.

Owner:叶川 +5

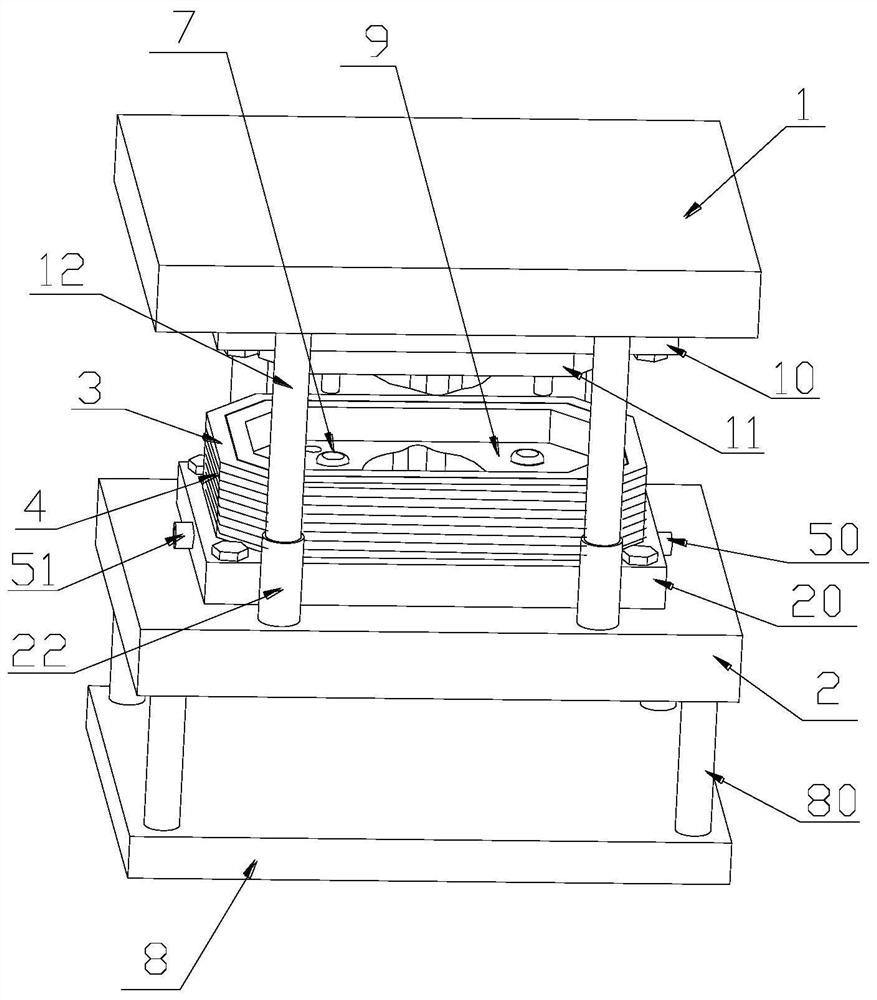

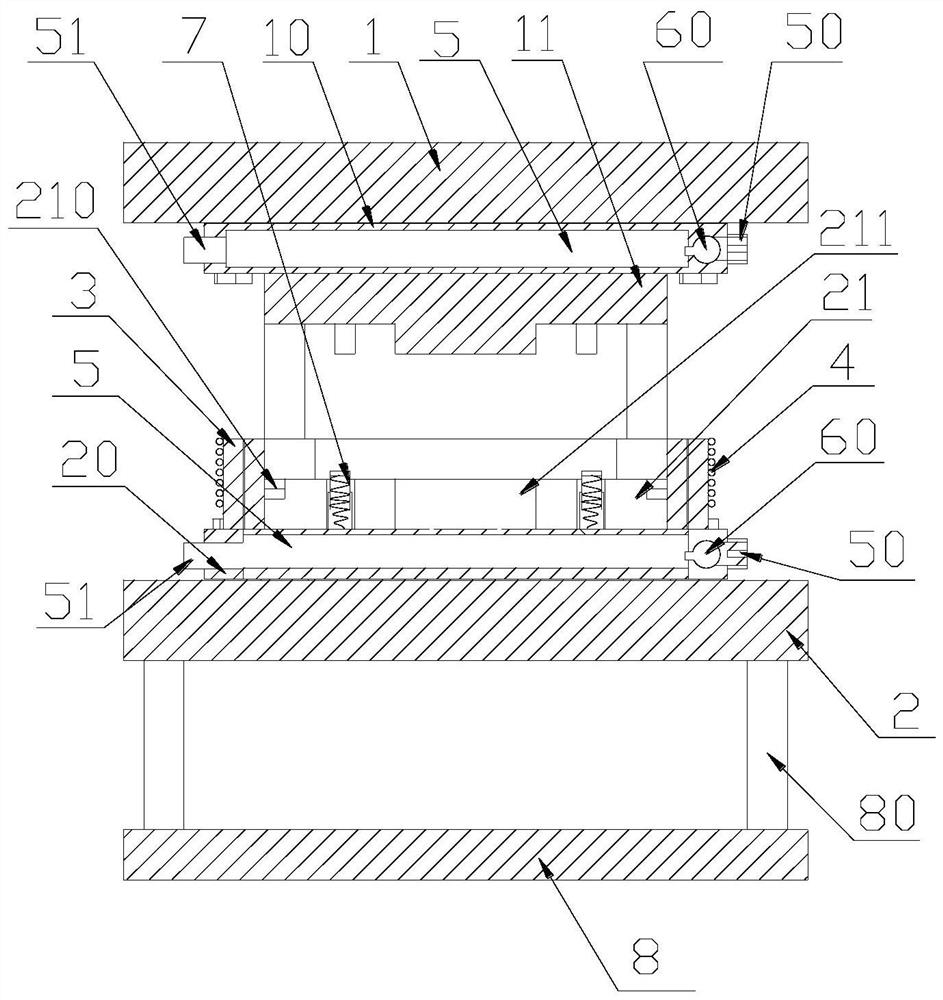

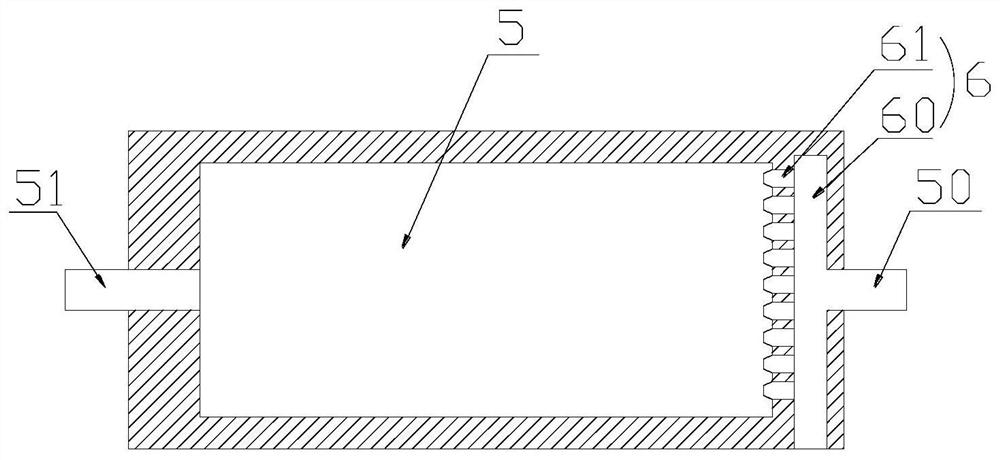

Soft magnetic alloy component hot extrusion die and preparation method thereof

The invention discloses a hot stamping mold for a soft magnetic alloy element and a preparation method thereof, wherein the mold includes an upper mold base and a lower mold base, and the upper mold base and the lower mold base are provided with mutually matching convex molds and concave molds, and the concave mold Including the lower mold body and the lower mold core, the punch includes the upper mold body and the upper mold core, the lower mold body has a graphite coating, and the outer surface of the graphite coating has an induction coil; the lower mold body corresponds to the position of the lower mold core, And there are cooling chambers in the position facing the upper mold core in the upper mold body, and the corresponding cooling chambers on the lower mold body and the upper mold body are equipped with inlets and outlets communicating with them. The preparation method mainly adopts the above-mentioned molds, through structural cooperation such as rapid heating and cooling, combined with measures such as heat preservation and pressure preservation. It can effectively increase the heating rate, cool down in time and ensure a stable cooling gradient, which can meet the preparation of complex structural components, and at the same time help to ensure the continuity of the internal grain structure of the finished soft magnetic alloy component, maintain good magnetic permeability, and improve the quality of the finished product .

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Highly compact ceramic ball of silicon carbide and preparation process thereof

The invention relates to a highly compact ceramic ball of silicon carbide and a preparation process thereof. The ceramic ball is prepared through carrying out steps of batch mixing, spray granulation, seed production, balling, and sintering on the following raw materials: 85-95% of a main material fine silicon carbide powder, 4-10% of a high char yield phenolic resin, 1-5% of a sintering aid, 1-10% of the weight percentage of the main material of a binder, and 0.5-3% of the weight percentage of the main material of a dispersant, wherein the binder is at least one of polyvinyl alcohol, dextrin, and carboxymethyl cellulose, and the dispersant is at least one of polyethylene glycolm, tetramethylammonium hydroxide, an aluminophosphate, and polyacrylic acid. According to the invention, active beneficial effects comprise that: 1, the ceramic ball of silicon carbide has the advantages of high density and stable chemical property; 2, the preparation process of the invention allows preparationof ceramic balls of silicon carbide with particle sizes of various specifications to be satisfied, so the ceramic balls with the particle size having a wide range of 1-50mm to be produced; and 3, theprocess is simple, one-time investment is less, and production expansion is easy.

Owner:HENAN XINDAXIN SCI & TECH

A kind of plastic preparation method of fiber layered structure preform

The invention discloses a molding preparation method for a tackified preform of a fiber layered-connection structure. According to the molding preparation method for the tackified preform of the fiber layered-connection structure, the tackified perform is woven according to a mold through a knitting method. The molding preparation method for the tackified preform of the fiber layered-connection structure is applicable to preparation of the tackified perform which is high in thickness, large in size and complex in shape; the molding preparation method ahs the advantages of being great in structural design performance, good in tackified perform homogeneity, excellent in mechanical property, high in fiber volume fraction, complete in block construction, continuous in yarn bundle, stable and controllable in dimension, high in preparation precision and suitable for preparing tackified perform complex in shape.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

Anti-immersion gold, anti-cracking matte white photosensitive solder resist material and preparation method thereof

ActiveCN105137716BGood attack performancePreparation to meetPhotosensitive materials for photomechanical apparatusResistLight sensing

The invention discloses a matt-white immersion-gold-resistant, anti-cracking and light-sensing solder mask material and a preparation method thereof. The matt-white immersion-gold-resistant, anti-cracking and light-sensing solder mask material mainly comprises a main agent and a curing agent, wherein the main agent comprises acrylic resin with a special function, acrylic resin, a photoinitiator, a dispersing agent, dibasic ester, fumed silica, barium sulfate, titanium dioxide and an antifoaming agent; the curing agent comprises thermocuring resin, a curing additive, melamine, a photocuring monomer, triglycidyl isocyanurate, titanium dioxide and dibasic ester. The prepared matt-white light-sensing solder mask material has high immersion gold resistance and yellowing resistance, and is more stable and reliable during normal technology use of a PCB (printed circuit board).

Owner:江门市阪桥电子材料有限公司

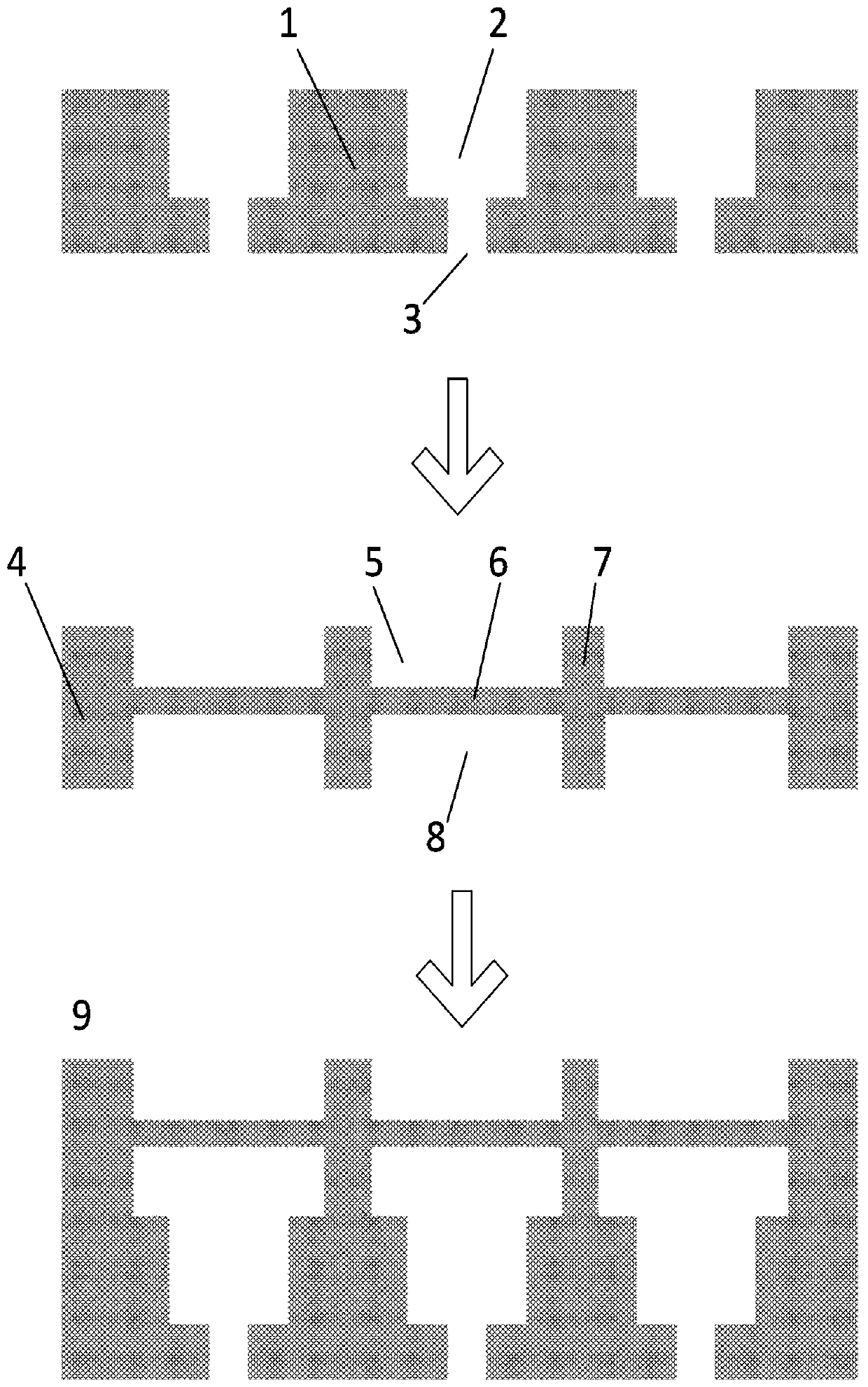

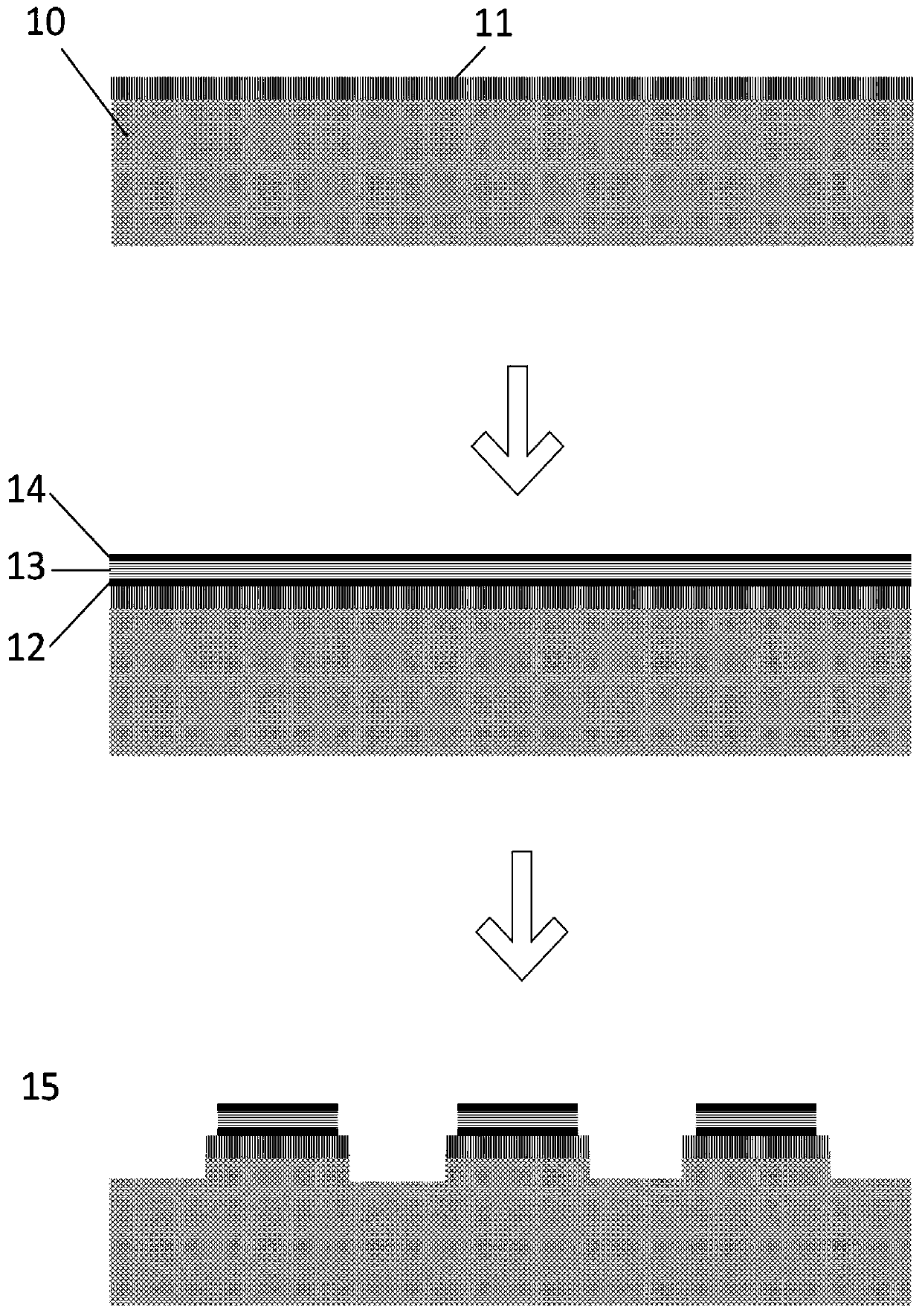

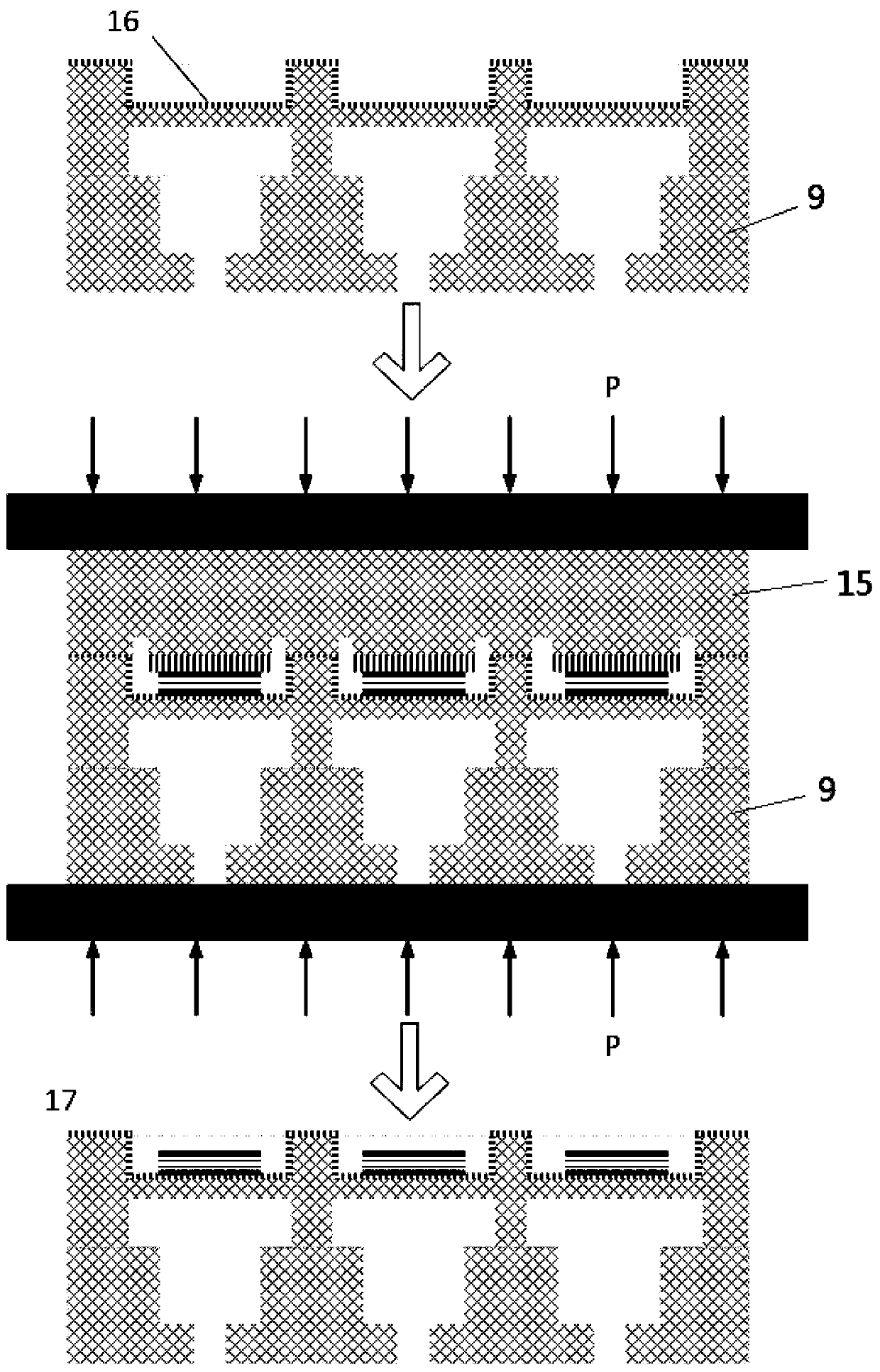

Transfer printing and manufacturing method of beam film type piezoelectric array printing head

ActiveCN110588177AStrong process compatibilityAvoid restrictionsPrintingEngineeringTransfer printing

A transfer printing and manufacturing method of a beam film type piezoelectric array printing head includes the steps of preparing a beam film type piezoelectric array printing head liquid channel plate, meanwhile independently preparing a beam film type piezoelectric array printing head piezoelectric driving plate, and combining a piezoelectric driving structure on the beam film type piezoelectric array printing head piezoelectric driving plate with the beam film type piezoelectric array printing head liquid channel plate through a transfer printing mode to form the complete beam film type piezoelectric array printing head. The method is high in technological compatibility and low in cost, and the beam film type piezoelectric array printing head with wide structure applicability is manufactured.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com