Soft magnetic alloy component hot extrusion die and preparation method thereof

A soft magnetic alloy and component technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of reducing the quality of finished products, magnetic attenuation, grain structure fracture, etc. The effect of magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with embodiment and accompanying drawing.

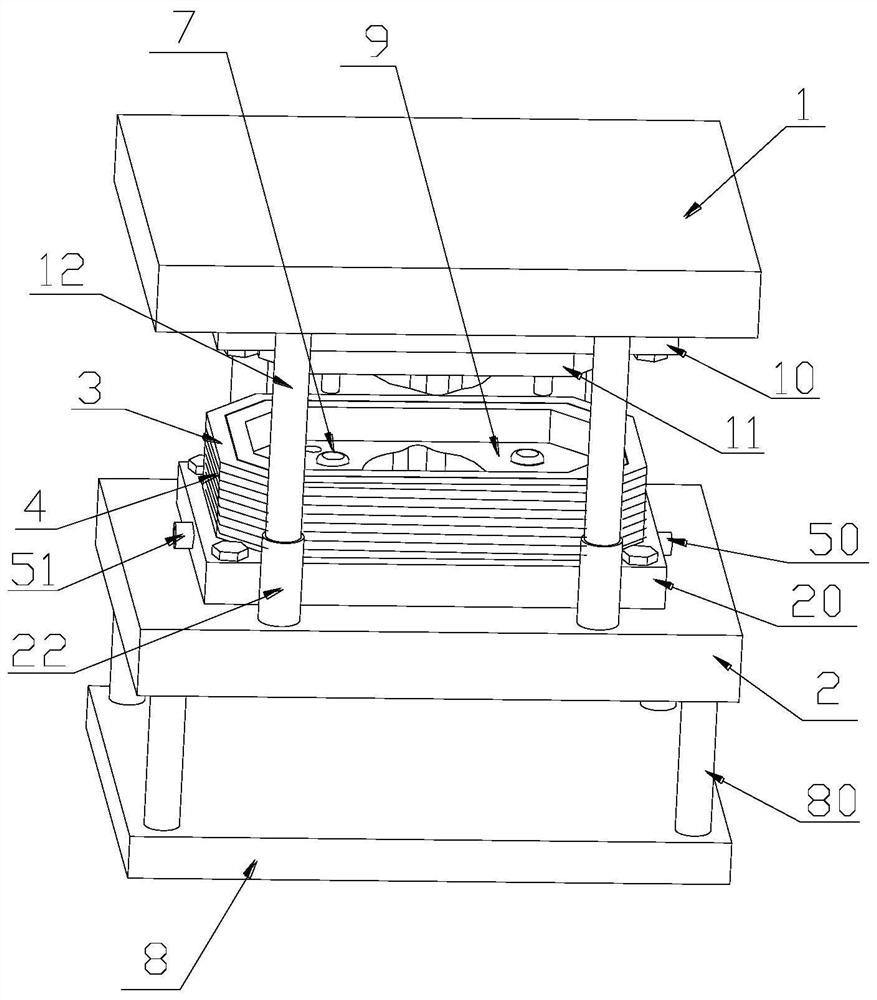

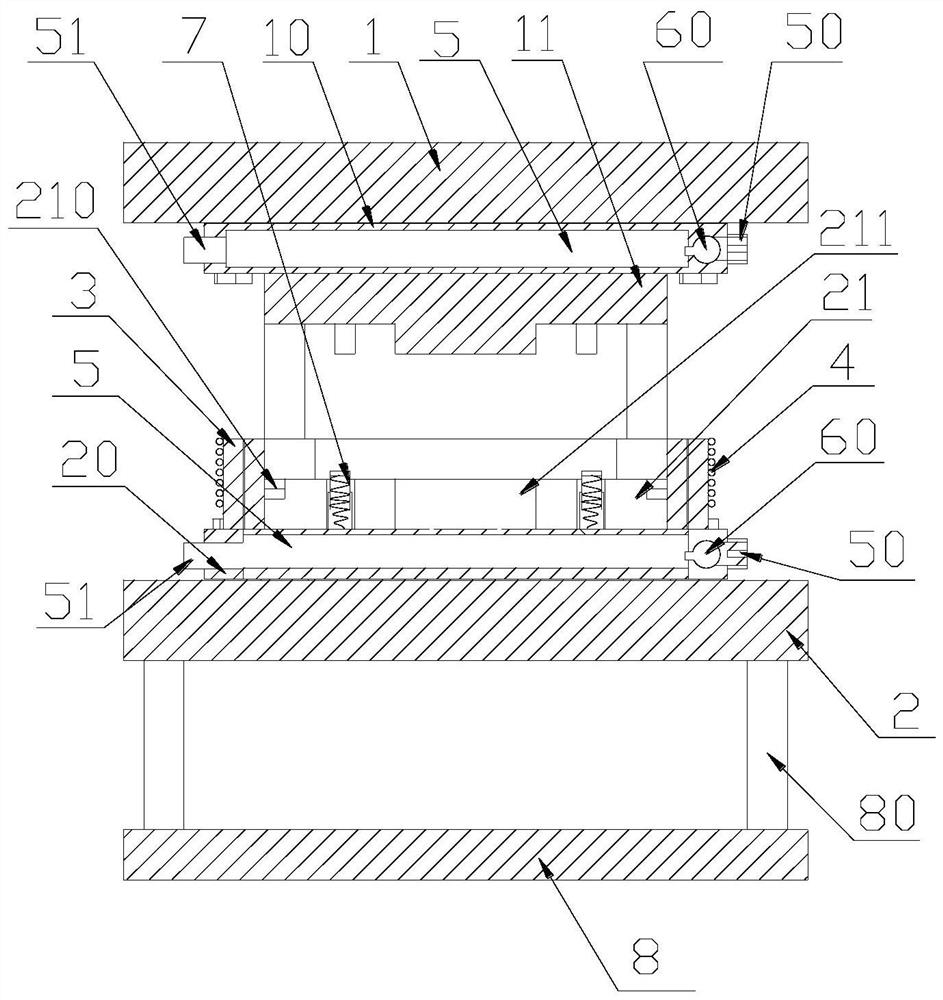

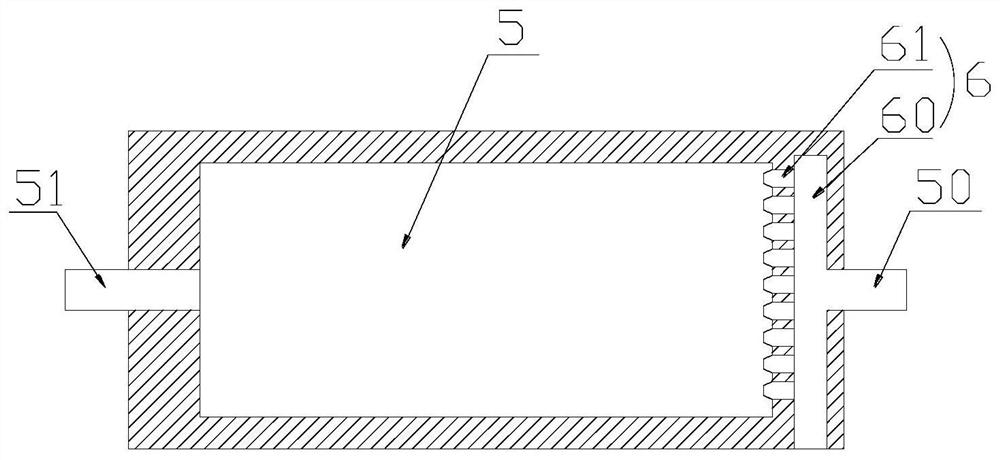

[0033] refer to Figure 1 to Figure 5 The shown soft magnetic alloy element hot stamping die and its preparation method, wherein the mold mainly includes an upper mold base 1 and a lower mold base 2, and the upper mold base 1 and the lower mold base 2 are respectively fixed with a punch and a die, And the punch and the die match each other, wherein the punch mainly includes an upper mold body 10 and an upper mold core 11 fixed on the upper mold body 10, the upper mold core 11 is arranged vertically downward, and the concave mold mainly includes The lower mold body 20, and the lower mold core 21 fixed in the lower mold body 20, as shown in the figure, the lower mold body 20 mainly includes an annular part that encloses the space suitable for the lower mold core 21, and the annular part is vertically arranged , and a support portion at the bottom of the annula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| magnetic permeability | aaaaa | aaaaa |

| coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com