Blood capillary network and making method thereof

A capillary and vascular endothelium technology, applied in the field of capillary network and its preparation, can solve the problems of inability to directly print micro-nano blood vessels, inability to accurately obtain two-dimensional and three-dimensional micro-nano structures of artificial blood vessels, and overcome important obstacles. , the effect of reducing energy consumption cost and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

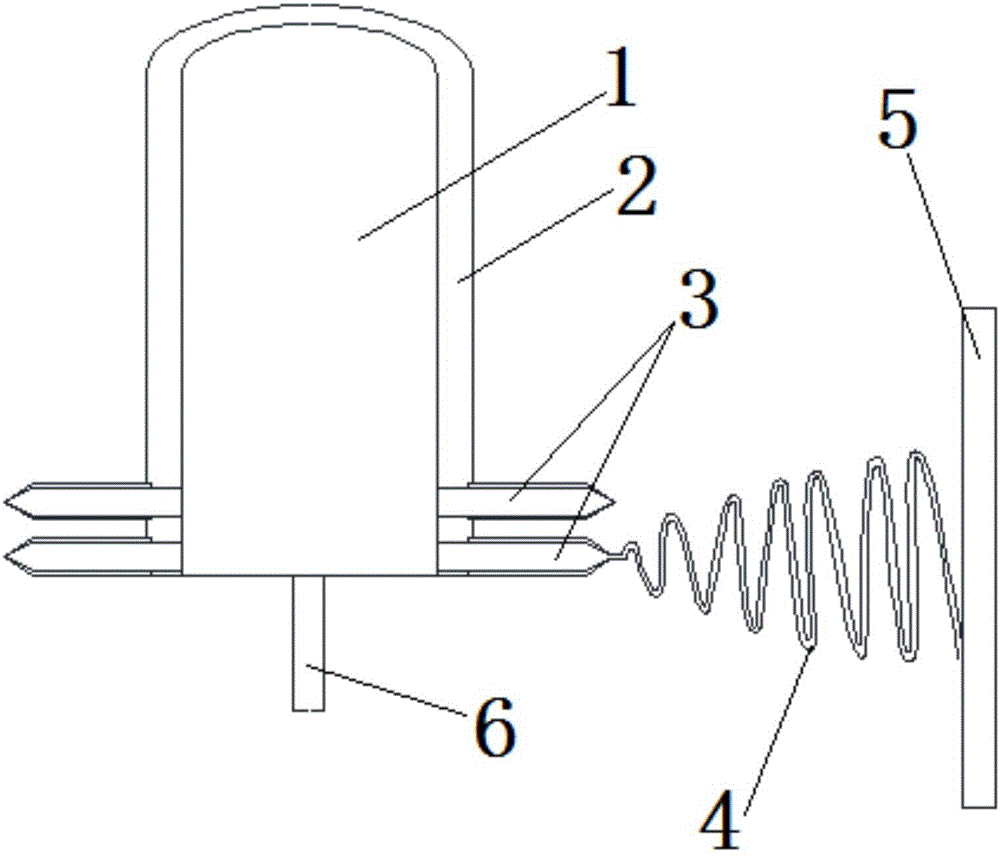

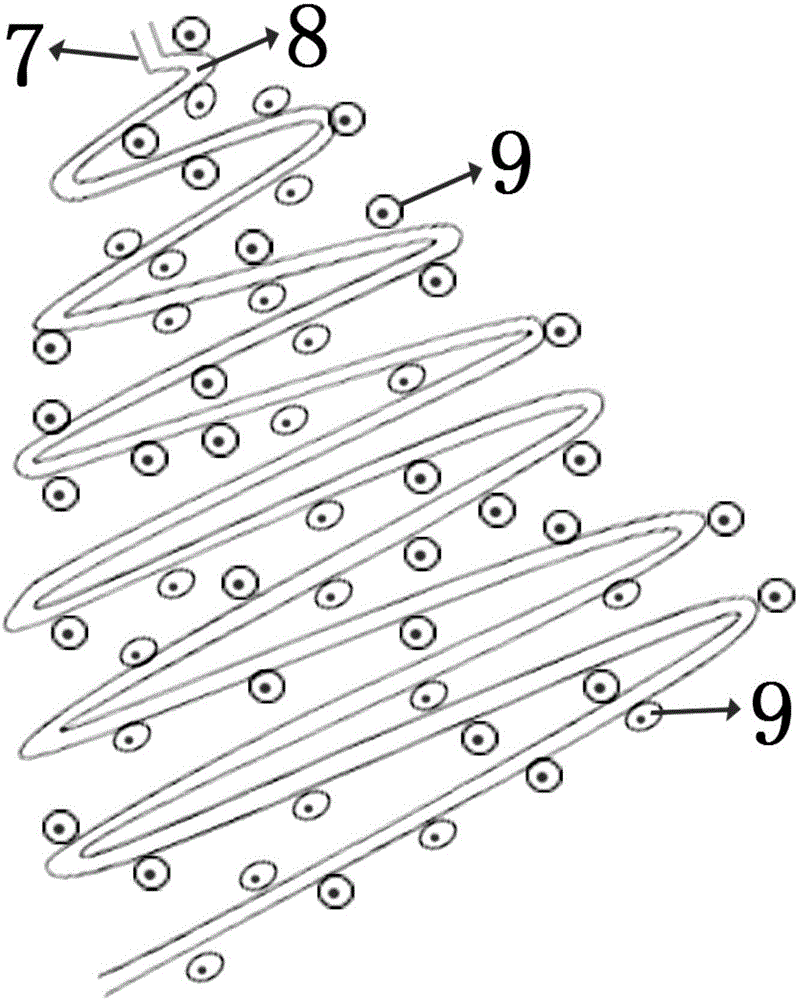

[0038] The present invention provides a method for preparing a capillary network. A soluble three-dimensional spinning net 4 is prepared by a centrifugal spinning method, and animal cells 9 are cultivated on the obtained soluble three-dimensional spinning net 4. The silk screen 4 grows and proliferates, and after the soluble three-dimensional spinning screen 4 is completely dissolved, a capillary network is obtained.

[0039] In view of the many problems existing in the prior art, the present invention uses a specific method to prepare a capillary network by means of centrifugal spinning. Centrifugal spinning is a high-efficiency and low-consumption micro-nanofiber preparation technology, and its principle is that polymer melt Or the solution is stretched into fibers under the action of centrifugal force after being thrown out from the spinneret hole. In this process, the centrifugal force plays an important role, and it has a certain compaction effect on the polymer melt or s...

Embodiment 1

[0070] A method for preparing a capillary network, comprising the steps of:

[0071] 1) Melt 50g of Tanghuatang and sterilize it under high pressure, then store it in a solution state for later use;

[0072] 2) Dissolve 5g of medical-grade polyvinyl alcohol in 50mL of ultrapure water to prepare a solution with a concentration of 10% by mass, and let it stand at 4°C after sterilization; then add vascular endothelial growth factor and alkaline The fibroblast growth factor is fully mixed with the resulting solution;

[0073] 3) Pour the solution obtained in step 1 and step 2 into a sterile high-speed rotating coaxial centrifugal spinning machine (sterilized) with two liquid storage cylinders inside and outside, respectively, to carry out coaxial centrifugal spinning; coaxial spinning The process conditions are: the inner cylinder solution is the shaft core material, the outer cylinder solution is the shaft shell material, the centrifugal speed is 3000r / min, the diameter of the c...

Embodiment 2

[0075] A method for preparing a capillary network, comprising the steps of:

[0076] 1) Melt 50g of white granulated sugar and sterilize it under high pressure, then save it in solution state for later use;

[0077]2) Dissolve 5g of medical-grade polyvinyl alcohol and 2.5g of medical-grade polyethylene glycol in 50mL of ultrapure water, sterilize the resulting solution and let stand at 4°C; then mix vascular endothelial growth factor and alkaline The fibroblast growth factor is fully mixed with the resulting solution;

[0078] 3) Pour the solution obtained in step 1 and step 2 into a sterile high-speed rotating coaxial centrifugal spinning machine (sterilized) with two liquid storage cylinders inside and outside, respectively, to carry out coaxial centrifugal spinning; coaxial spinning The process conditions are: the inner cylinder solution is the shaft core material, the outer cylinder solution is the shaft shell material, the centrifugal speed is 4500r / min, the coaxial nozz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com