Device for preparing ultrafine particles using supercritical fluid

A technology of supercritical fluid and ultrafine particles, which is applied in the direction of granulation of raw materials, solution crystallization, chemical instruments and methods, etc., can solve problems such as unbearable for customers, single function, and difficult to reach the working state.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

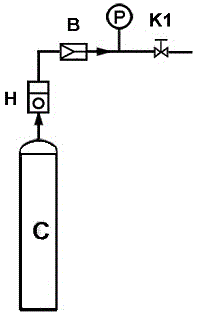

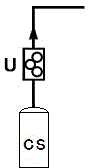

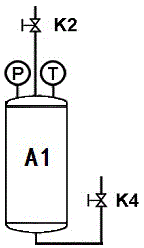

[0053] In this example, in Figure 1 to Figure 11 , the symbols of all components in the figure are as follows:

[0054] symbol illustrate C Supercritical Fluid Cylinders H fluid cooler B carbon dioxide pump CS Entrainer container U Entrainer booster pump A1 The first reactor A2 The second reactor S Splitter RN heating nozzle R mixer CL collector E1, E2, E3... Exit 1, 2, 3... K1, K2, K3... Valve 1, 2, 3... ,P pressure gauge ,T thermometer

[0055] In this example, see Figure 1 to Figure 11 , the device for preparing ultrafine particles using supercritical fluid is composed of a supercritical fluid supply device, an entrainer supply device, a reactor and a separation device as the main functional modules, and is composed of system splicing through different assembly and connection methods, and is characterized in that, By setting a series of auxiliary valves ...

Embodiment 2

[0075] This embodiment is basically the same as Embodiment 1, especially in that:

[0076] In this embodiment, for the supercritical fluid extraction unit, the seventh auxiliary valve K7 and the eighth auxiliary valve K8 are opened, and when the entrainer needs to be used, the entrainer filled in the entrainer container CS is pressurized by the entrainer The pump U is pressurized to generate high-pressure entrainer fluid, and the high-pressure entrainer fluid flows into the first pipeline between the sixth auxiliary valve K6 and the first inlet valve K2 after the pipeline where the seventh auxiliary valve K7 and the eighth auxiliary valve K8 are located. The pipeline node N1 merges with the high-pressure entrainer fluid prepared by the entrainer supply device. After the high-pressure entrainer fluid and the supercritical fluid are mixed and mixed, the fluid is controlled to enter the first reactor A1 by controlling the first inlet valve K2. Under the temperature and pressure s...

Embodiment 3

[0078] This embodiment is basically the same as the previous embodiment, and the special features are:

[0079] In this embodiment, for the supercritical solution rapid expansion particle preparation unit, the seventh auxiliary valve K7 and the eighth auxiliary valve K8 are opened, and when the entrainer needs to be used, the entrainer filled in the entrainer container CS is passed through the entrainer The agent booster pump U is pressurized to generate high-pressure entrained agent fluid, and the high-pressure entrained agent fluid flows between the sixth auxiliary valve K6 and the first inlet valve K2 after the pipelines where the seventh auxiliary valve K7 and the eighth auxiliary valve K8 are located The first pipeline node N1 of N1 merges with the high-pressure entrainer fluid prepared by the entrainer supply device. After the high-pressure entrainer fluid and the supercritical fluid are mixed and mixed, they enter the first reactor A1, and in the first reactor A1 Under ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com