A device for preparing ultra-fine auxiliary gates by extrusion for crystalline silicon cells

A crystalline silicon cell, extrusion technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of difficult to control the aspect ratio of screen printing, difficulty in online monitoring and maintenance, and the waste rate of silver paste. Achieve the effect of improving photoelectric conversion efficiency, solving maintenance and large-scale production, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

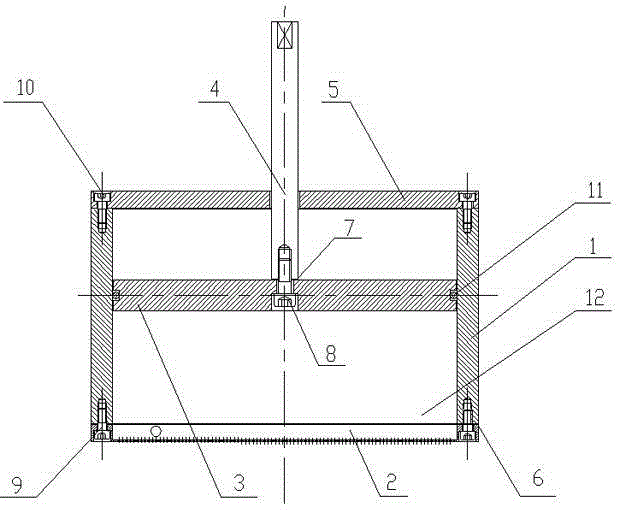

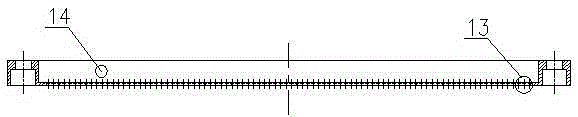

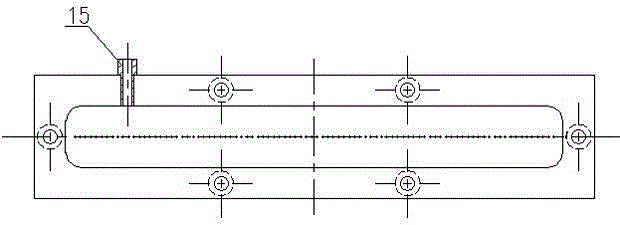

[0023] A crystalline silicon battery extrusion method to prepare ultra-fine auxiliary gate device, such as Figure 1-Figure 4 As shown, including nozzle cylinder, nozzle, piston, piston rod, nozzle end cap, first sealing ring, second sealing ring, hexagon socket screw, O-ring, silver paste, nozzle, threaded hole and external threaded pipe connector.

[0024] Such as figure 1 As shown, the spray head 2 is fixedly connected with the spray head cylinder 1 through the hexagon socket head cap screw 9 , and the first sealing ring is installed between the spray head 2 and the spray head cylinder 1 . The piston 3 is fixedly connected with the piston rod 4 through a hexagon socket head cap screw 8 , and the second sealing ring is installed between the piston 3 and the piston rod 4 . The spray head end cover 5 is fixedly connected with the spray head cylinder 1 through a hexagon socket head cap screw 10 . The O-shaped first sealing ring 1 is installed in the groove of the piston 3 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com