Preparation method of quantum dot, quantum dot/UV glue solution and quantum dot doped optical fiber

A technology of quantum dots and colloid solution, which is applied in the field of nanomaterials and optical communications, can solve the problems of toxicity and high material cost, and achieve the effects of less impurity, high dispersion and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] Specifically, the quantum dot preparation method provided in the embodiment of the present invention includes the following steps:

[0050] 1) According to Cu(CH 3 COO) 2 : Zn(CH 3 COO) 2 =(1~10): 1, Zn(CH 3 COO) 2 : SnCl 2 =1:(1~5) molar ratio Weigh reagents, add to 10~100mL of octadecene (Octadecene, ODE), under vacuum or inert gas atmosphere, heat the solution to 100~150°C, stir evenly, until the metal salt is completely dissolved;

[0051] 2) Add 0.5-5mL of dodecanethiol (DDT), and keep warm at 100-150°C for more than 10 minutes;

[0052] 3) Add 0.2-2mL oleic acid (Oleic acid, OA), and keep warm at 100-150°C for more than 10 minutes to remove water and dissolved oxygen in the solution;

[0053] 4) Rapidly raise the temperature to a reaction temperature of 200-300°C and keep it warm for 2-50 minutes to obtain a dark brown liquid;

[0054] 5) After the product solution is cooled to room temperature, vigorously mix and shake according to the volume ratio of pr...

Embodiment 1

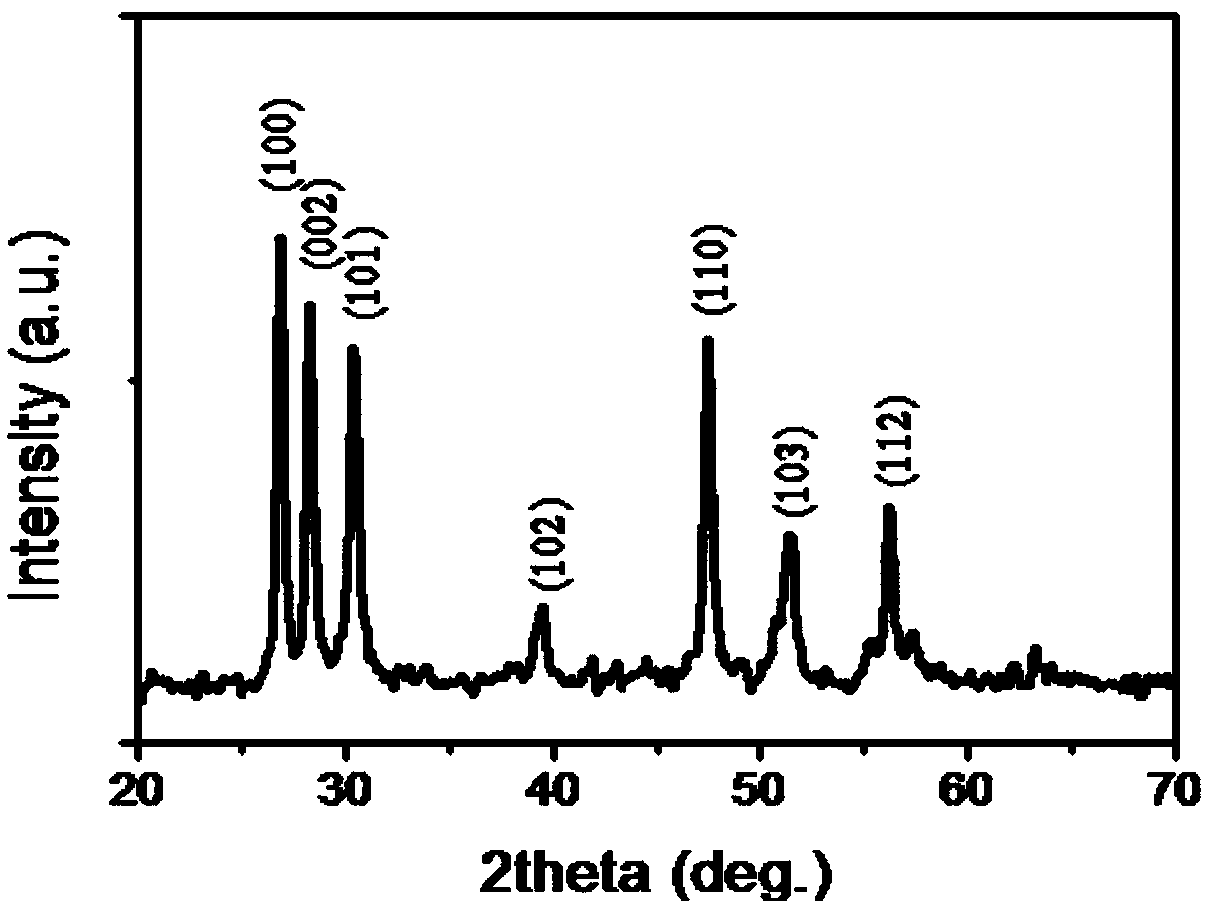

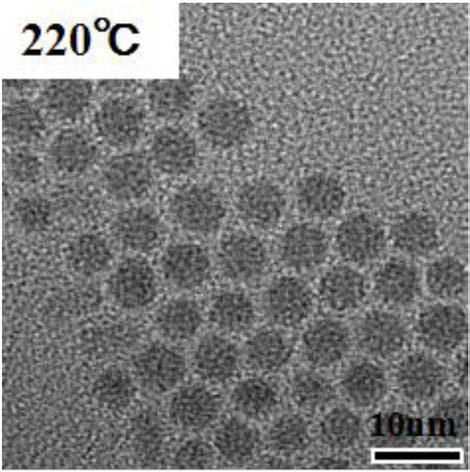

[0058] Take analytically pure 1mmol Cu(CH 3 COO) 2 , 0.5mmol Zn(CH 3 COO) 2 , 0.5mmol SnCl 2 And 20mL ODE was placed in a three-necked flask, stirred evenly at 120°C under vacuum until the metal salt was completely dissolved; 1mL DDT was added, and kept at 120°C for 10min; then 0.5mL OA was added, and the solution was heated to 120°C for 10min; quickly heated to Reaction temperature 220°C, keep warm for 20min, wait for the product solution to cool to room temperature, vigorously mix and shake according to the volume ratio of product solution: methanol = 1:3, centrifuge at 6000-8000rmp, and obtain 3.6nm Cu after centrifugal purification 2 ZnSnS 4 quantum dots. figure 2 It is the Cu prepared by the quantum dot-doped optical fiber preparation method provided by the embodiment of the present invention 2 ZnSnS 4 The transmission electron microscope figure of quantum dot, the Cu that this embodiment obtains 2 ZnSnS 4 Quantum dot transmission electron microscope picture as ...

Embodiment 2

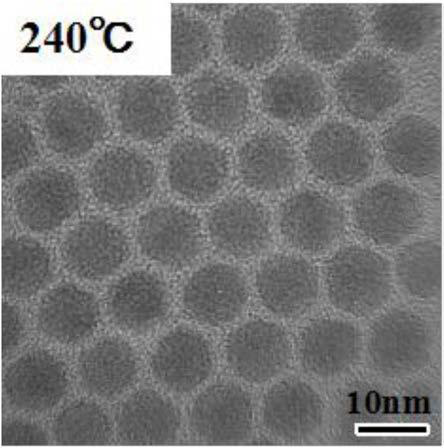

[0060] In this example, except that the reaction temperature was 240°C, the temperature was kept for 20 minutes, and 5.3nm Cu was obtained after centrifugal purification. 2 ZnSnS 4 Quantum dots, other reaction conditions and implementation process are the same as in Example 1. image 3 It is the Cu prepared by the quantum dot-doped optical fiber preparation method provided by the embodiment of the present invention 2 ZnSnS 4 The transmission electron microscope figure of quantum dot, the Cu that this embodiment obtains 2 ZnSnS 4 Quantum dot transmission electron microscope picture as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com