Preparation method and application of ethyl silicon oil

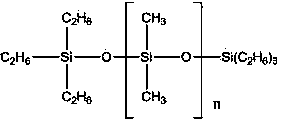

A technology of ethyl silicone oil and ethyl cyclosiloxane, which is used in pharmaceutical formulations, cosmetic preparations, cosmetic preparations, etc., can solve the problems of high residual acid value of ethyl silicone oil and cannot be used in cosmetics, etc., and achieves molecular weight The effect of uniform distribution, controllable viscosity and low acid value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 350Kg hexaethylcyclotrisiloxane, 5Kg hexaethyldisiloxane, 1.75Kg cerium magnesium phosphotungstate (Mg 0.5 Cs 1.5 h 0.5 PW 12 o 40 ) stirring, the temperature is controlled at 40°C, ring-opening polymerization is carried out for 4-6 hours, the catalyst is removed by filtration, the temperature is raised to 180°C, and the low molecular weight is removed by controlling the vacuum degree above -0.095MPa to obtain clear and transparent ethyl silicone oil 1.

[0023] The single-pass conversion rate of ethyl silicone oil 1 is 85.62%, and the viscosity is 100mm 2 / s (25°C).

Embodiment 2

[0025] Add 350Kg hexaethylcyclotrisiloxane, 6Kg hexaethyldisiloxane, 1.75Kg cerium aluminum phosphotungstate (Al 0.5 C 0.5 PW 12 o 40 ) stirring, the temperature is controlled at 70°C, ring-opening polymerization for 4-6h, the catalyst is removed by filtration, the temperature is raised to 200°C, and the low molecular weight is removed by controlling the vacuum degree above -0.095MPa to obtain clear and transparent ethyl silicone oil 2.

[0026] The single-pass conversion rate of ethyl silicone oil 2 is 86.73%, and the viscosity is 75mm 2 / s (25°C).

Embodiment 3

[0028] Add 350Kg octaethylcyclotetrasiloxane, 4Kg hexaethyldisiloxane, 4Kg cerium aluminum phosphotungstate (Al 0.1 Cs 2.2 h 0.5 PW 12 o 40 ) stirring, the temperature was controlled at 100°C, ring-opening polymerization was carried out for 2-3 hours, the catalyst was removed by filtration, the temperature was raised to 150°C, and the low molecular weight was removed by controlling the vacuum degree above -0.095MPa to obtain clear and transparent ethyl silicone oil 3.

[0029] The single-pass conversion rate of ethyl silicone oil 3 is 84.58%, and the viscosity is 300mm 2 / s (25°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com